Quick update,

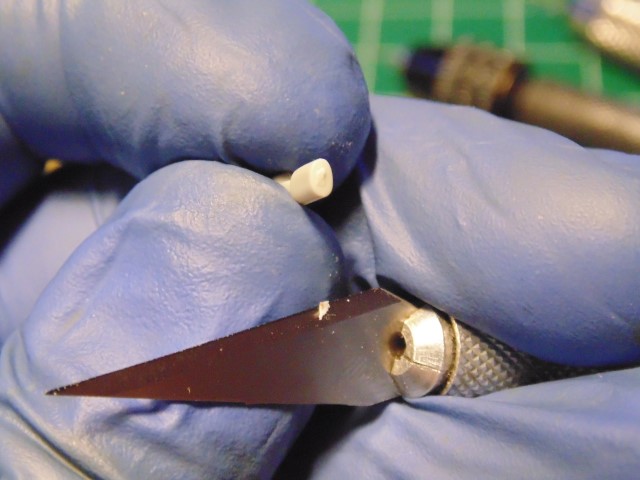

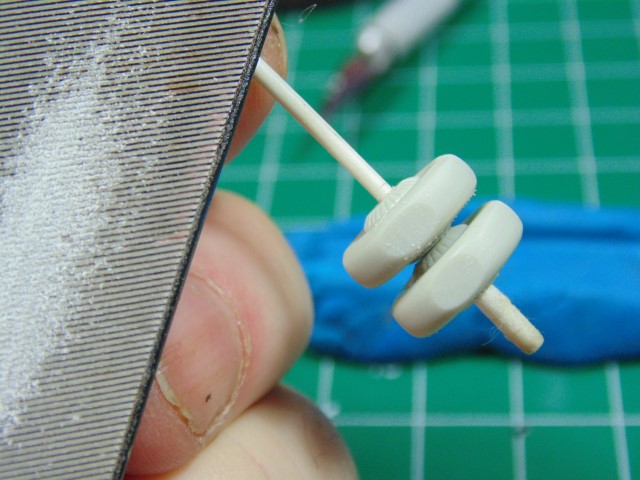

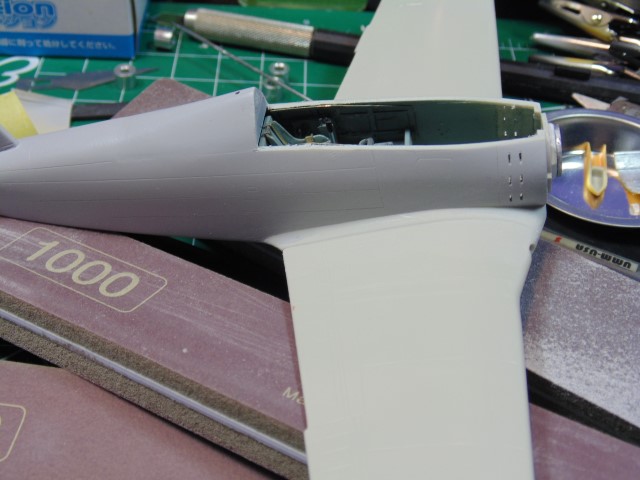

The “massaged” cowl parts need to be carefully assembled in order to find out the exact amount to sand down the resin engine cylinder tops.

I removed my Barnes Kilt and sprung for a decent brush (yeah scots are known to be frugal). This Martha Kolinski AK unit will dark feathering the panel lines ever so slightly, yet will definitely be noticed. The quality of this brush is (insert expletive here) tremendous.

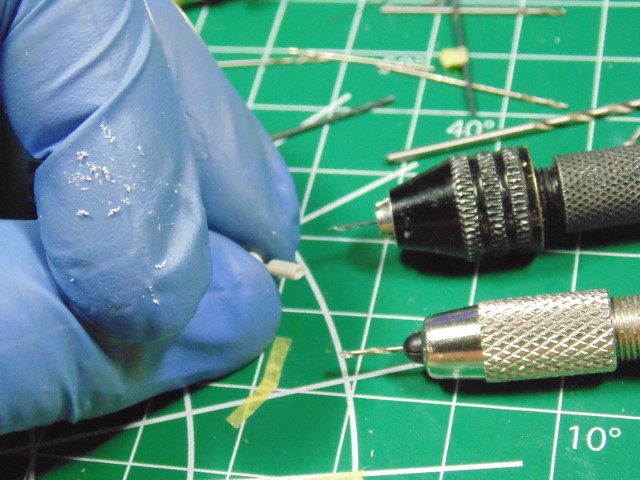

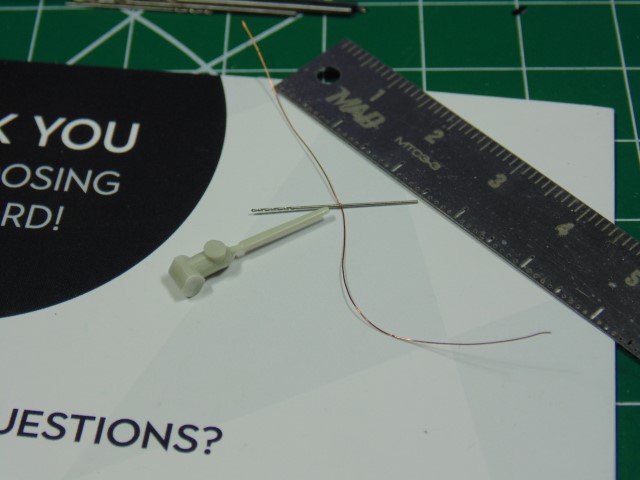

The bottom intake part is messy. It was gently cleaned up with reaming tools and painted where the owner will be able see the interior. I’ll be adding a grease pigment 502 wash later. Also the panel lines were rescribed due to being really soft. I added a demarcation line for the back segment which have the under-body color.

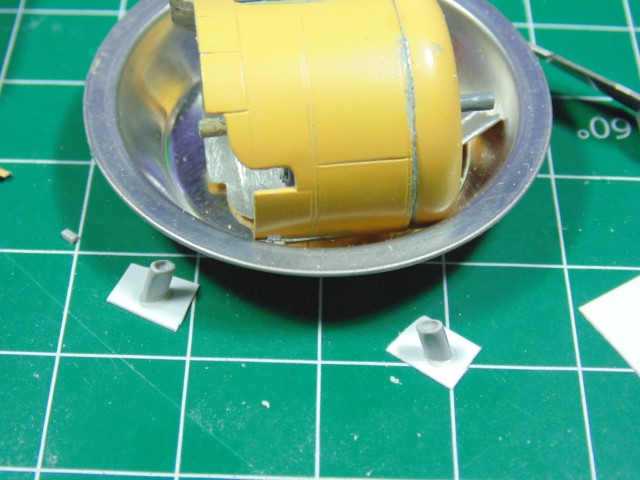

Naturally, the insides of all the cowl parts were first primed then sprayed with aluminum. It will barely be noticed, yet worth the few hours since it’s going to a nice home.

After the interior color was fully hardened some poster tac held the parts on AK sticks. Remember, all the plastic was removed from the inside for the engine fitment. I use 6 different brands of lacquer paint, but AK RLM 79 (1941) has that eased off yellow which is perfect for Italian WWII replication tones, in my opinion.

Still a ways to go on this one, however progress is progress. Huge thanks to Sunward Hobbies for sending my tools so quickly in order to get this update to you. God bless.