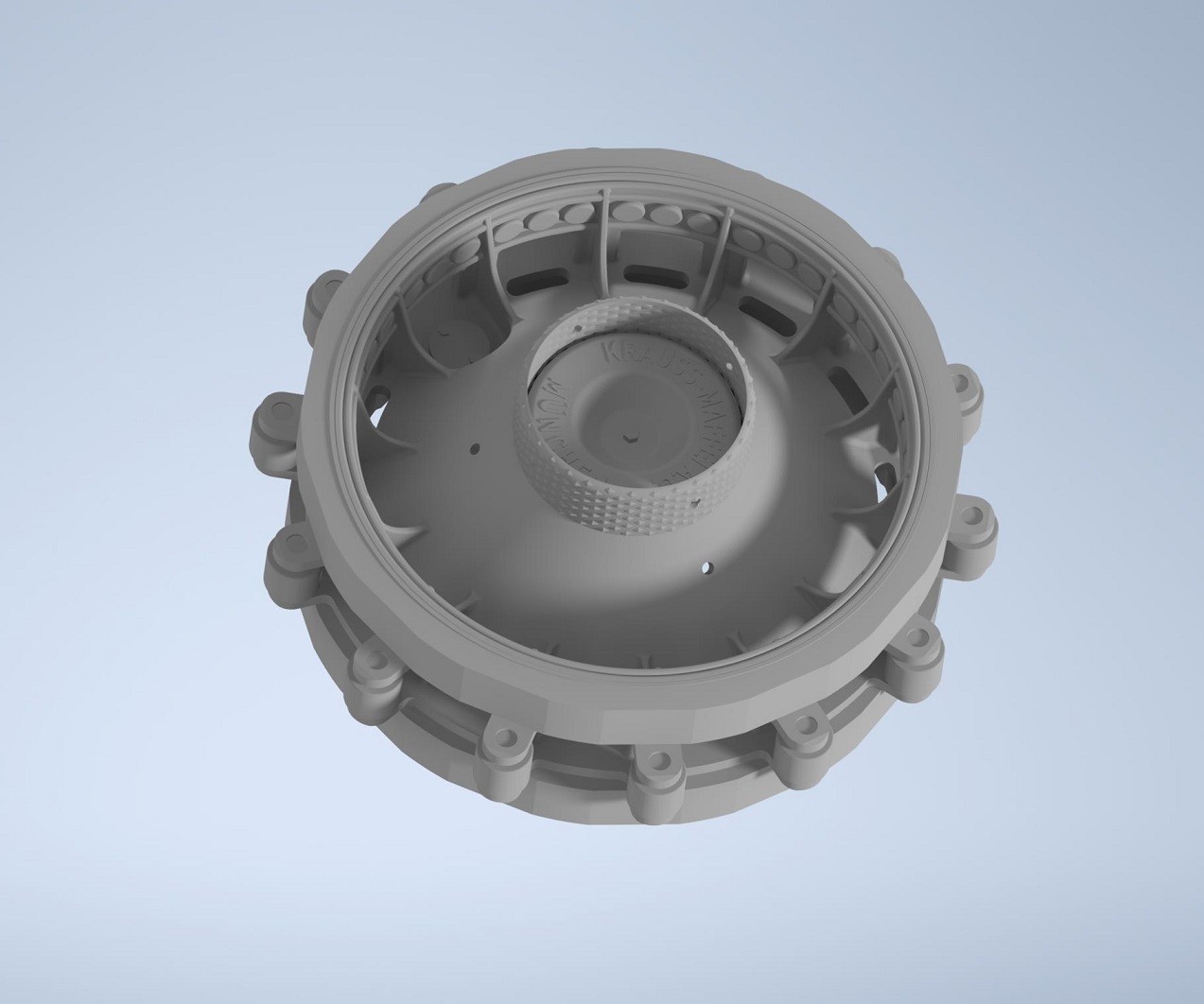

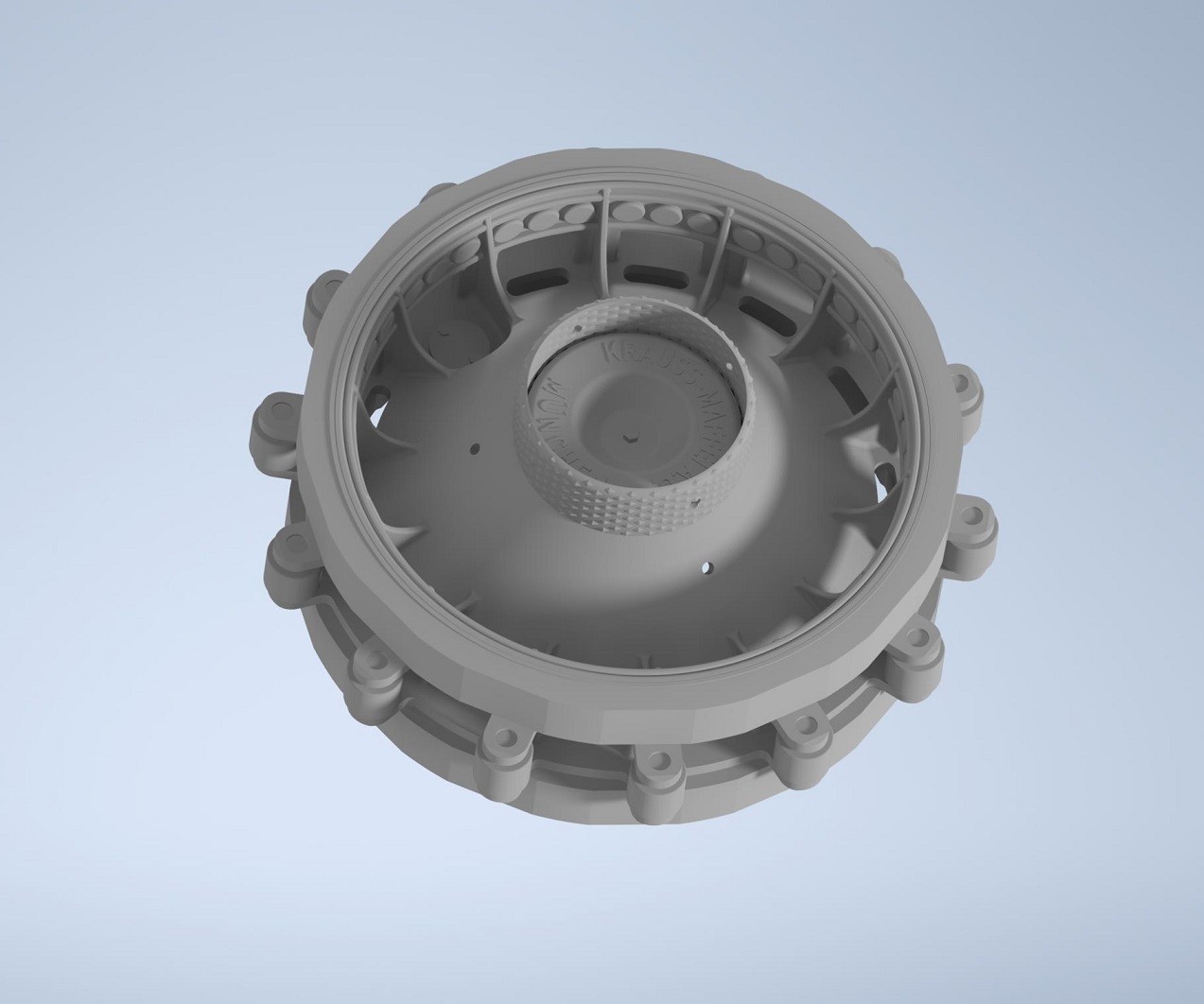

New designs from HomeBrewParts for Dragon Sdkfz7/1 - 7/2 armored cab halftracks,

This is partial text from the full article (usually with photos) at https://armorama.com/news/homebrewparts-sd-kfz--7-detail-sets

New designs from HomeBrewParts for Dragon Sdkfz7/1 - 7/2 armored cab halftracks,

Not that these aren’t nice when removed from printing gates and really cleaned up but I have no desire to have to be that careful and take all that time when I can get something on another medium just as nice. There is a company that makes printed tracks for the M 18 hellcat from Tamiya that come cleaned up.

Some of these items look great…. I would certainly be interested in purchasing, but I believe it’s the model files that are for sale… and you have to print them yourself? Which is a pity… as I don’t have a 3D printer!

Correct, they sell the file for you to print. Nowadays it is not that hard to find a friend who has one or get a printing service in your town.

As for the printing supports, trees, if correctly designed they are quite easy to clean. Most of them simply snap off leaving very little behind if any. This is not like traditional resin, I prefer removing a bunch of 3D supports than a casting block from resin.

Additionally, the cost of the designs is much lower, and you can print them unlimited times.

this are only the files you have them print by yourself so it depends how good your printer will print this stuff and there is no company behind it that sends you the ready made Item.But you have to try print it without supports ![]()

You can’t print it without supports, it would simply fail to print. You’d need a slicer program like Chitubox or Lychee to make supports and then slice the file so the printer can read and print the part. I honestly don’t see the benefit over purchasing pre-printed and processed parts from people like myself, James, or any number of other vendors other than cost. Yes, it’s more expensive, but it comes with the convenience of not having to buy a 3D printer, learn to use a 3D printer, learn to use slicer software, learn how to effectively print using that slicer software, reprint failed prints, then take the time to clean up the print that finally succeeded. This guy makes some amazing looking models. I think if he sold the prints directly he’d do pretty well.

Most printing service will clean up 90% of the pins for you, it is the least of their problem in the 3d printing business. Filament is easier to print, but it can’t get to the detail level that we are used to. 3D printing with resin has a very steep curve to learn and upfront price. Unless you plan on making a business related or extreme dedication, it is not viable.

I know this was ironic addition for this comment.Infact sometimes it is possible if the parts lay on the plate