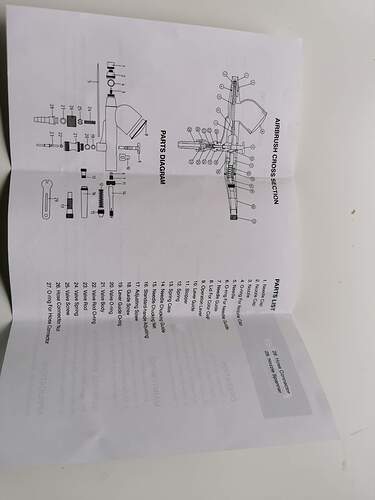

As recommended above, you’ll start at the rear with the nut that holds the needle and work your way forward to the tip.

A suggestion is lay the parts out in the order that you remove them and in the same general orientation that they had in the airbrush. Reassembly will generally be in the reverse order of disassembly, so, if the parts are laid out in a line, you’ll just start reassembly with the last piece removed. Keeping the parts oriented in the same way they were in the airbrush will help you get them oriented correctly during reassembly (if you forget how they go).

Note that the trigger (button you press to spray) and its bearing will likely drop out once the needle has been removed. Pay close attention to the orientation of these parts. The bearing will probably have a curved side that has to be correctly installed. It can likely be installed backwards, so be aware of it.

You don’t need to disassemble the air valve that the trigger presses down on (where the hose connects to the airbrush).

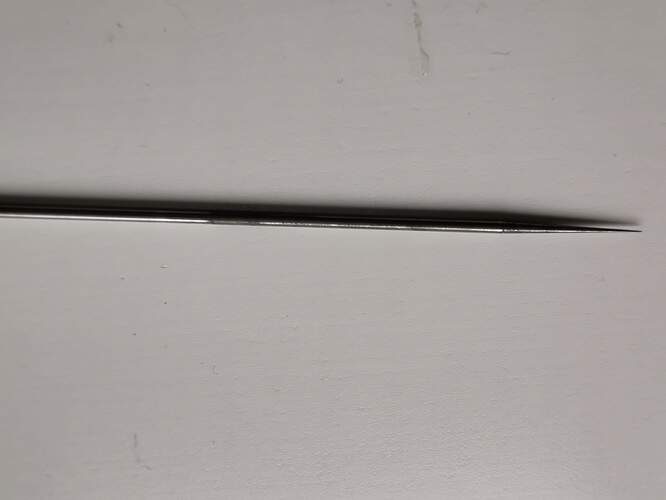

When you reinstall the needle (after reassembling the tip), gently push it all the way forward (to close the paint tip), then tighten its locking nut at the rear of the handle. The needle should fit in the paint tip to close it, but it needs NO FORCE to do this.

You want to be sure that when the return spring has pushed the trigger all the way forward, that the needle has also moved to close the paint tip. However, you don’t want any forward pressure on the needle in the tip as it sits closed. It should be in a neutral position, but closed. The return spring should only exert pressure on the needle as the trigger is pulled to the rear.

Your brush might have a stop or adjustment to limit the amount of paint that can flow (it will stop the trigger from moving to the rear at a point that you chose). If your airbrush has this feature, you should open it up fully before you disassemble it. This makes it easier to be sure all of the adjustments work and the needle has full range of motion once the airbrush has been reassembled. (With practice and experience you will not need to do this later. The orientation of the parts and their range of movement will become understandable.)

If you remove the locking nut for the needle, and it does not want to pull out easily to the rear, then consider adding a few drops of lacquer thinner (cellulose thinners) into the paint cup and allow it to soak for a few minutes. A ring of dried paint around the need where it enters the paint cup can damage the o-ring air seal as you pull the needle out. Take care here. If it has been a while since you cleaned the airbrush well, you might have some trouble with this.

(This is one of those areas that you should clean routinely. The needle should slip out easily every time you disassemble it. If it does not, then you need to clean more often.)

Consider using a very small brush of the kind sold for flossing between your teeth to clean out the paint channel between the tip and the paint cup. Again, lacquer thinner can help to soften up old, dried paint collected in the this area.

(Again, this is an area that can cause problems unless cleaned regularly. No matter how much thinners you spray through the brush after painting, paint will build up in this channel. When it does, it will block the flow of paint.)

If your paint tip is clogged with dried paint, consider soaking it in lacquer thinners. This may take some time. If you cannot get all the paint out of it, you can carve / whittle / trim a wooden cocktail stick (wooden tooth pick) down to a very fine, thin point and use that to clean out the paint tip. IF YOU DO THIS, be VERY careful. This is the tip that you mention you split on your old airbrush. If you force the cocktail stick into it, you can do the same damage again.

However, a trimmed down wooden cocktail stick is better than trying to use a piece of wire or a sewing needle for this same purpose.

(Again, the paint tip is an area that is prone to clogging unless it is cleaned periodically.)