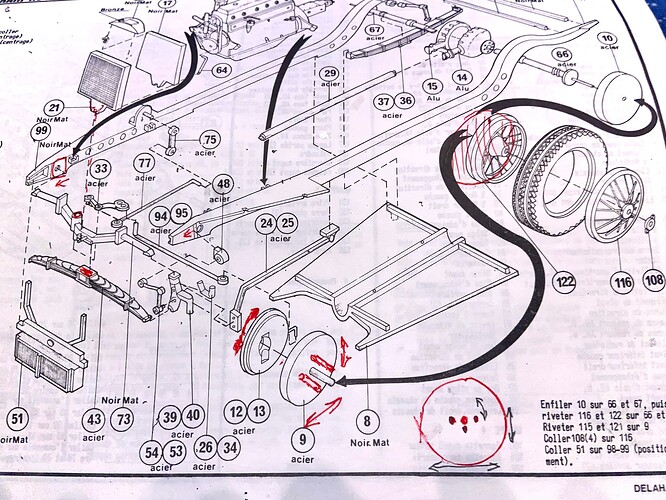

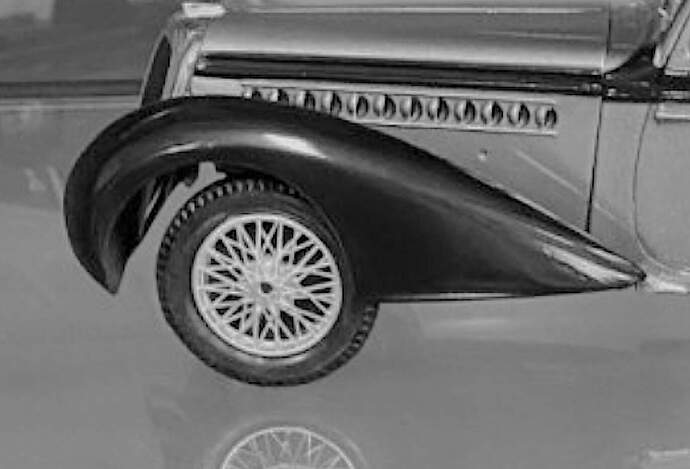

This 1/24 Heller Dehalaye 135 kit is on my ‘pre bench’. It is known for one specific build issue, the front wheels are not centered in the wheel arch. Also imho,

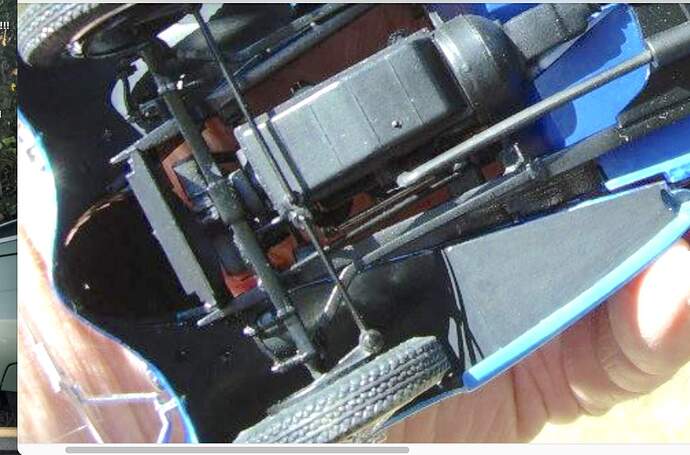

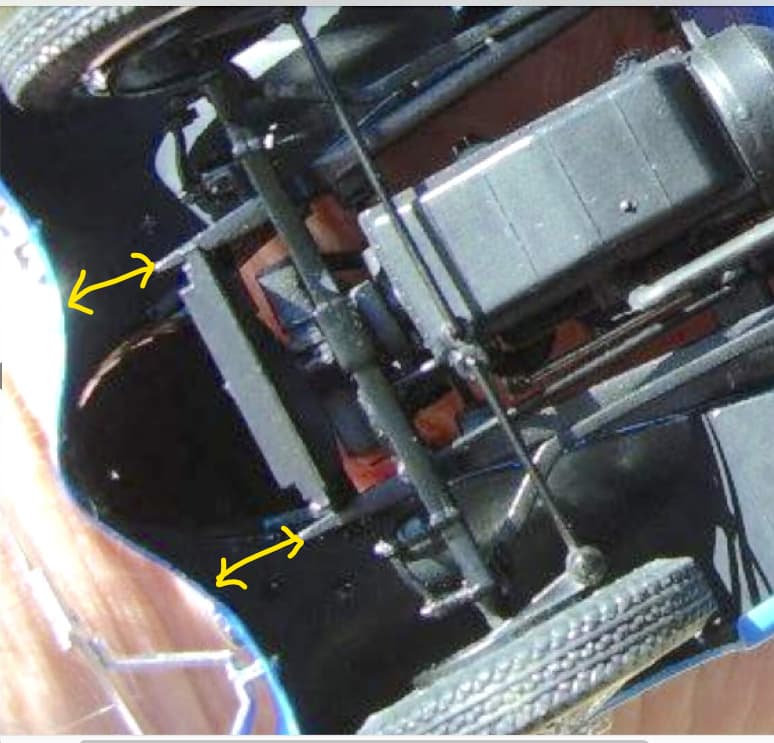

the entire chassis sits too high (I’m suspecting by 1-2 mm?) and the rear wheels in particular sit a bit too ‘recessed? Aka the stance needs work. I haven’t looked yet at how to correct this chassis height and probably because I haven’t, I don’t think that will be as challenging as the front wheel/axle reposition? First solutions that come to mind on this are:

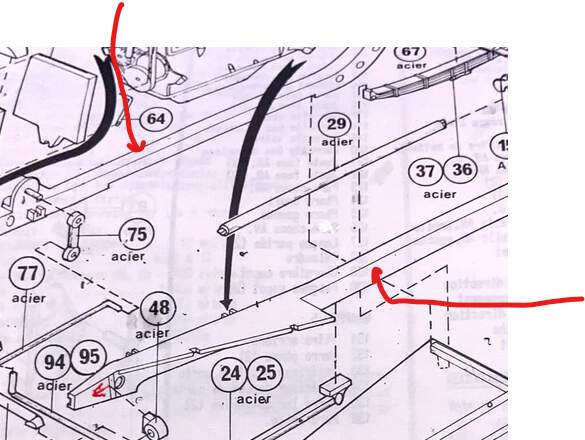

- lengthening the chassis at the front cross

member / axle

(this looks direct and perhaps inviting until you start building the front end steering and engine install and I think the problems in the reposition multiply?)

-

relocating the front axle forward

(I did this once on another build, using sliding styrene tubes. It facilitated positioning the axle easily, but this vintage chassis on frame design presents problems hiding this fix?)

(also the parts here are small and delicate with small attachment points, especially in contrast to the 1/8 Pocher kits I build?) -

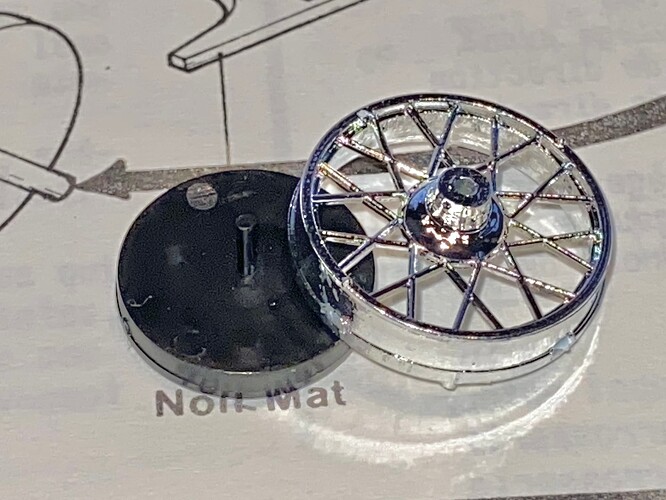

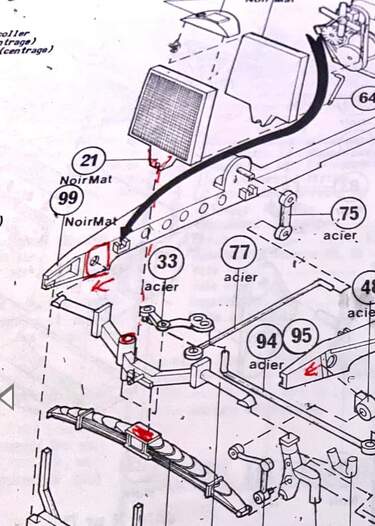

Even using upgraded PE wire wheels as I will here, the kit ‘axle brake plate (P9) with ‘post’, fits into the completed 2 piece wire wheel (P122-116). My current idea is to add a few ‘off center’ holes in the’”axle brake plate” (P9) to allow me to cut the kit post off and via trial and error of fitting interference fit new positionable posts into “axle brake plate” (P9)? That means converting the front axle geometry from concentric to an elliptical movement as the wheel is turned? I think this will, in a perfect world, both move the wheel on the X & Y axis: both ‘re centering’ and lowering the axle center? By positioning these ‘holes’ at varied distances from center,I hope to find a better wheel position? The issue then is how to address looking thru the wire wheel to see the off center backing plate (P13). My fix is to cut a thin circle from stock as a backing disc behind the wire wheels?

Any comments appreciated from anyone smoking something different……? Thanks

Clarence Novak