@twong, thanks. As for the lift kits and fitting the tires, neither was all that straight forward, but, as it turns out, I’m a bit of a 4x4 nut, so likely overworked the process to get what I wanted.

First up, the Chevy:

I did a lot of work on the Chevy, so I figured why not do the same on the suspension?

For the chassis and body, it was shortened about 14 scale inches to allow for the scratch built step side bed, so plenty going on.

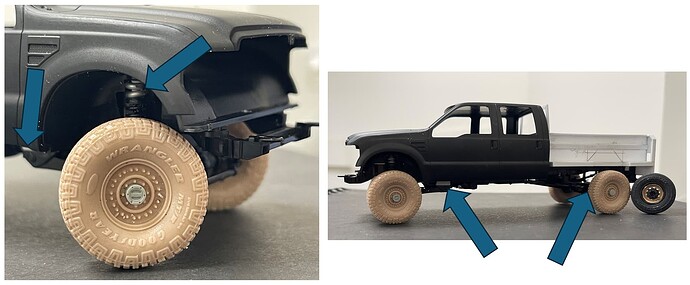

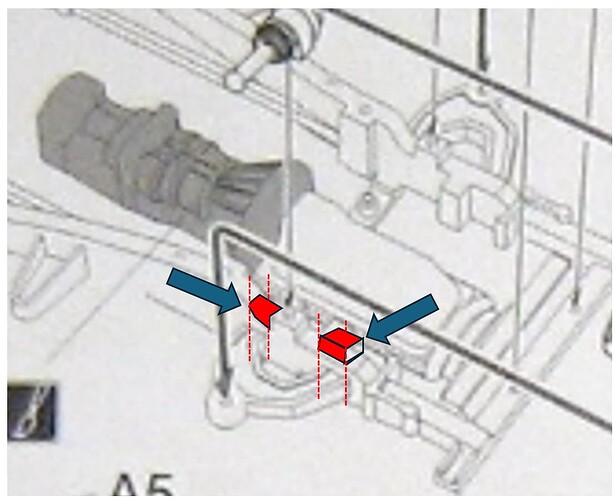

In the rear, I added spacer blocks, but cut them at a slight angle, to clock the differential to slope upward, in order to keep the driveline at a respectable angle toward the transfer case. The block in the rear goes between the leaf pack and axle, where the blue arrow on the left is pointing.

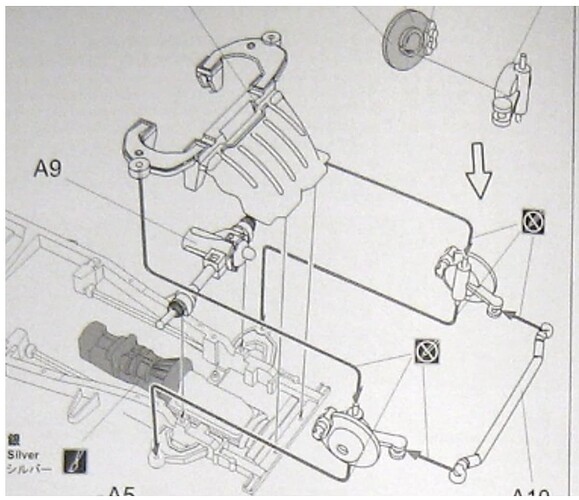

The front was a bit more complicated, as using blocks for the front lift is structurally unsound (in real life, the shear associated with steering when moving can result in the blocks popping out - not a good situation). To resolve this, I cut the kit’s front and rear shackles apart so that they could be rotated and relocated (described below) to also re-clock the differential, as shown by the two blue arrows pointing downward.

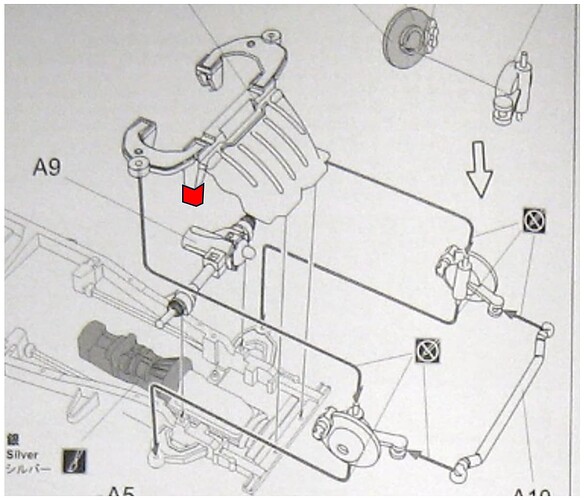

The lift itself came from re-arching the front springs. In the kit, they sag ( a lot like the real truck), but for a properly lifted front axle on springs, they are replaced with positive arch sets, like the rear. In English this means bending the leaf springs upward. This also means they get shorter. In real life this is not a problem because the replacement springs are longer, so they fit. I was not in the mood to make new leaf packs, so instead relocated the aforementioned shackles on the frame, moving both closer together keeping in mind the axle center line relative to the fender opening.

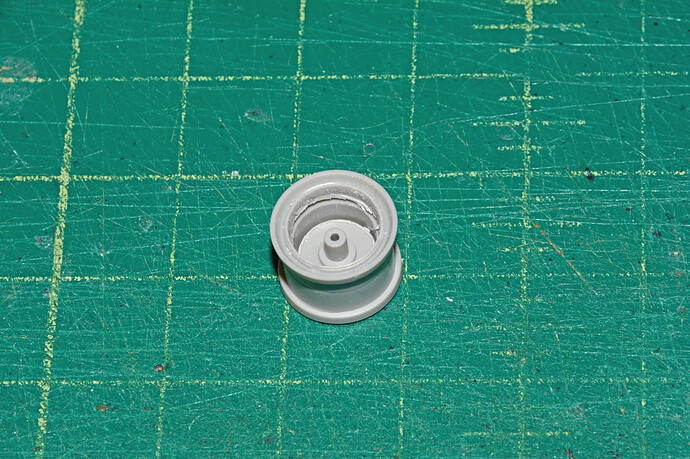

The kit allows for posable but not moveable steering - that is, you can set it left, right or centered, and as I wanted to leave it adjustable when done, I made up some relatively fussy upper and lower ball joint assemblies - in brief, horseshoes of styrene that serve as retainers for the ball joint pins provided in the kit, as shown in the picture on the right. This is not as hard per se as it sounds, but it is pretty tricky, as you want to firmly attach the horseshoe, but not get any glue on the ball joint pin.

Then, as I’ve destroyed many a drag link in my day, well, I set it up to have styrene, alu tube and thin steer rod heim joints, so it remains moveable and strong. What a treat!

Should you not want to embark on this path, you could likely get away with using front and rear blocks beween the axles and leaf springs!

And the Ford, the 37" tires would be a very tight fit, but my guess is they might work - as always, dry fit first!

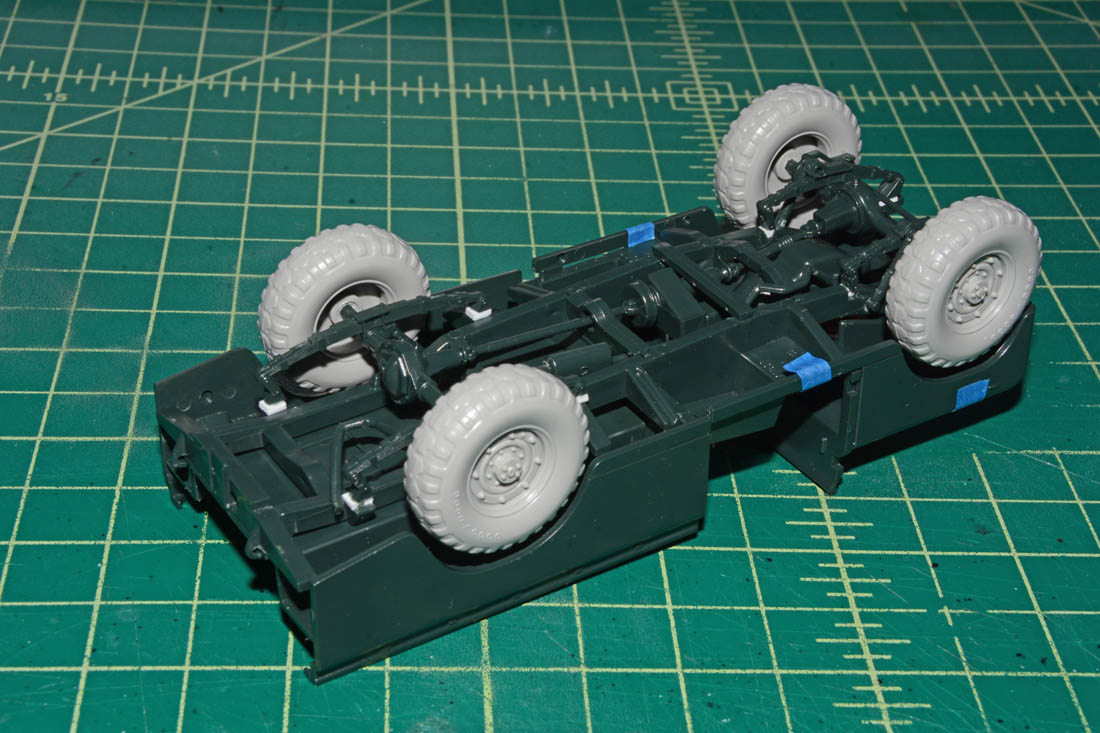

But, that’s not what I did, and instead gave it a legit lift so they’ll fit:

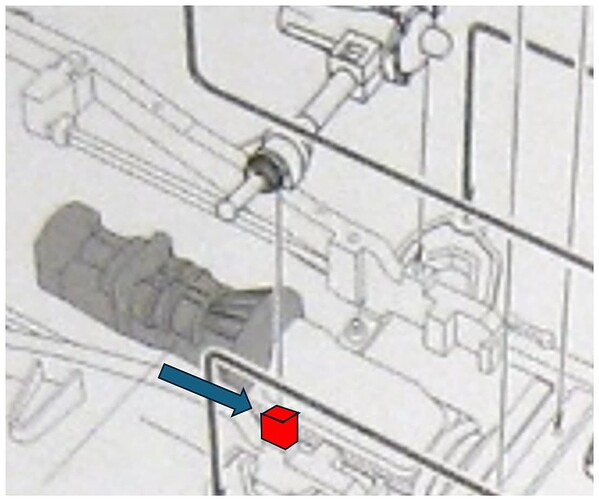

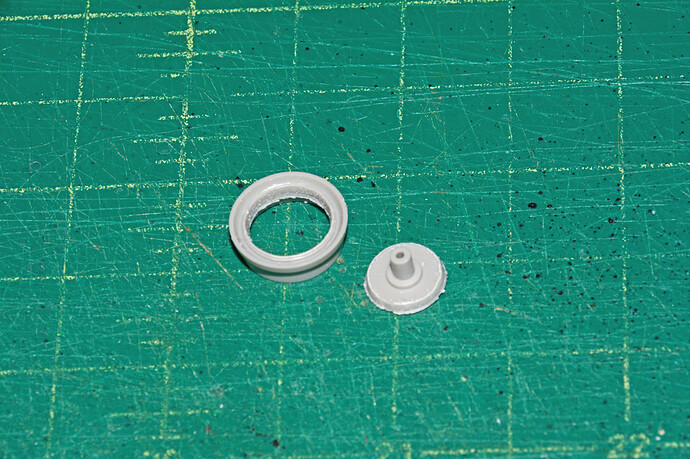

For the front, I extended the front coil spring and added a piece of styrene rod, which when combined, extend the kit provided spring parts, and the styrene adds stability and by providing a solid mounting point, and shown in the picture on the left, and called out by the arrow at the top of the coil.

By doing this you provide the lift, but this means the radius arms are too low, and you’ll get a bad angle and not much of a connecting point. To address this, I adapted the rear side of the radius arm bracket - and I’m sorry to not have a good picture of this, but below the arrow on the left side of the picture barely shows the white styrene used. You might get a better view looking at the pic on the right, and the arrow toward the front of the truck.

Finally, the rear only gets a lift block as described above, between the axle and leaf pack.

As you can see on the pic on the left I added locking front hubs, and on the rear a full floating hub. You can also see a comparison of the new tires and those from the kit - the new ones are much bigger. It looks like the kit provides a small factory tire, maybe 29"? This truck also got a loggers box, so a completely new bed.

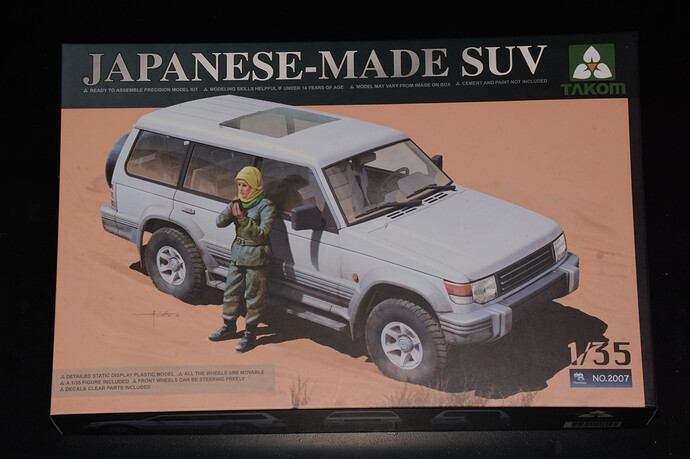

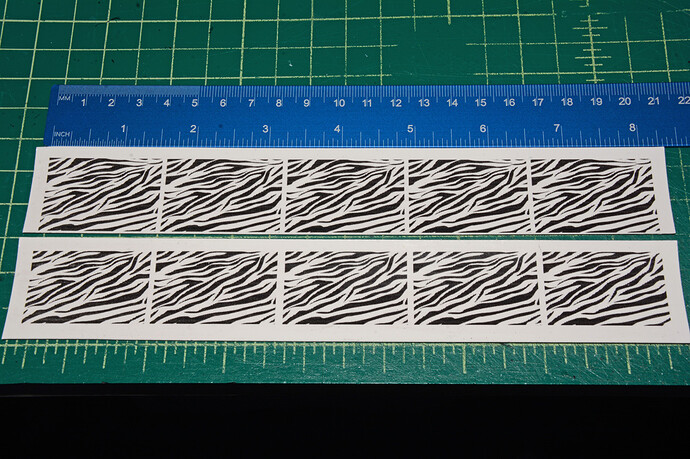

I’ve built a couple of the Toyotas too, and they also went together well - I think I added a minor lift to a land cruiser pickup, but as it’s such a small kit, did what I could to keep the conversion fairly straight forward, but did some cutting too:

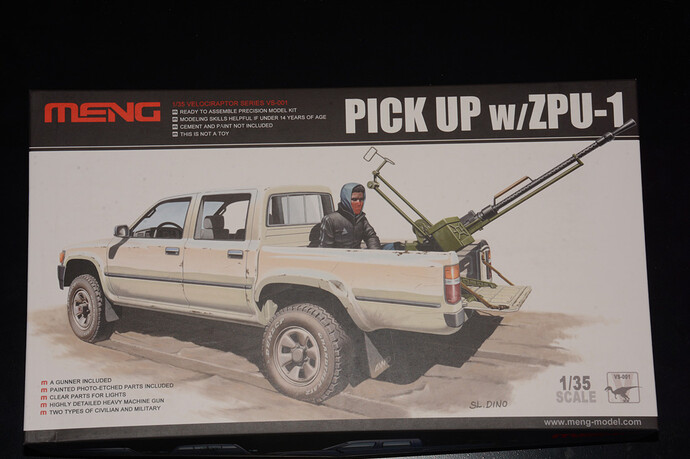

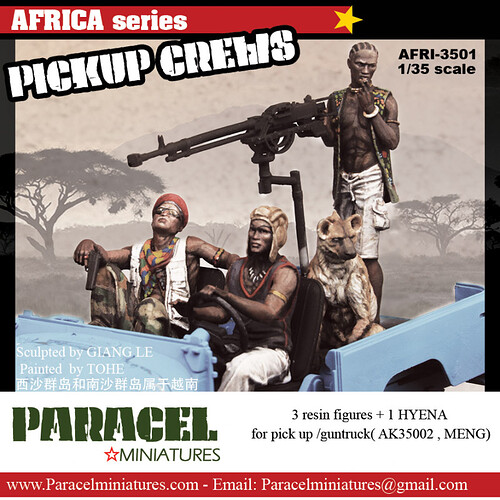

In closing, both kits (AK and Meng (2)) are very good as is, and the process described is not needed - unless, you want to convert the truck to something with more off road capability or style differences, like the step side conversion, or if you’re a truck nut too!

OK, hope some of this is of use! Looking forward to seeing your builds!

Cheers

Nick