A PAUSE THAT REFRESHES

Before continuing with the windows in the nose, HG has been occupied with

making stuff to get stuff together. Made two pairs of tweezers, two jars of clear styrene filler and did hours of polishing and fine sanding. Stuff that has to be done … One big job was washing the wings down! As mentioned some time ago, it’s IPA [Isopropylalkohol] then warm soapy water and scrub and spray with airbrush then fresh water to rinse and spray dry. Nice and clean with gloves only from now on with those parts.

He continues:

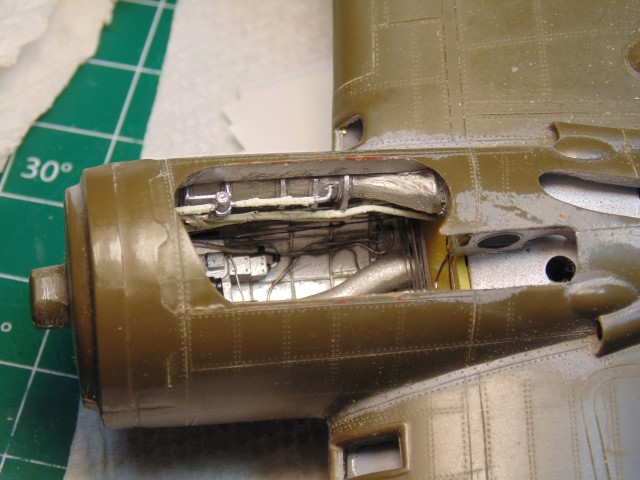

I also added the promised extra pipes in the wheel bays. I may add even more due to the different pictures I have. The two hooked looking ones at the back of each bay are important and done, they are in all the L/R photos.

Finally, HG has made a major effort to get the landing lights in the wing “just right.” He writes me:

Thought for sure I’d got these landing light covers all worked out, but gosh darn-it! The outer side of the left wing stands proud and there’s a noticeable gap. The red stuff is filler.

The black blob is plastic filler. Once it dries I’ll sand it to match the clear part so it’s smooth.

The red light part was shaped, hollowed, painted white then a dab of clear red.

The picture with the one black dot is how I know where to drill the hole in the right spot. Just a tiny bit of paint on the location pin and press it down to leave the mark.

Same thing was done with the red light

While doing this HG states:

I’ve come up with a way now to get those f-ing windows done thanks to the break from working on another section. Next up is the other landing light and, if all goes without a snaf-foo, priming the wings

.Slowly but surely, it is coming together.