Hello, first time over here since the forums moved…I’m working on a Merkava Mk IV, and have settled on the thinned white glue/grit approach to applying anti skid. What I’m not 100% on is do you:

- Apply to the bare plastic, then prime to seal, or

- Prime first (which could cause some white glue wicking with the primer being rough itself) or

- Something entirely different?

Any help greatly appreciated.

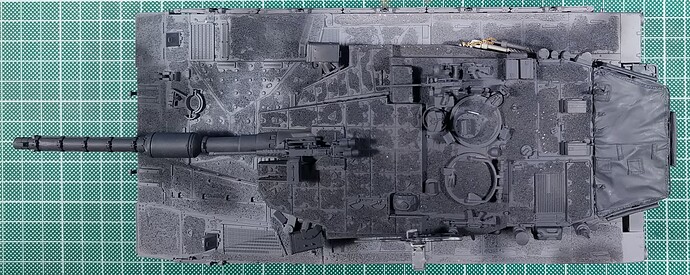

I laid it straight on the bare plastic, then primed and painted over the top. I primed to seal the rough medium on but I used VMS Hull Tek on my Merkava and it came out brilliantly.

1 Like

Thanks. VMS uses a liquid base that mildly attacks the styrene? Any issues with that part? I assume it gives a very solid grip to the texture.

What are you using for grit?

If your grit is too fine than avoid using many primer/paint/varnish layers on top of it. If it is more coarse you can apply first, then prime and then apply the rest of the layers of paint and varnish.

I am using a relatively coarse grit so I use Mr Surfacer 1200 as glue on which I apply the grit, then prime with Ultimate primer and then paint, varnish etc. (I tend to use many layers of paint and varnish so by the end the antiskid will look more subtle than at first.)

Thanks, and very nice build. I have some embossing powder that looks pretty in scale. When using Mr. Surfacer 1200…that stuff tends to be thick and dry fast. How do you thin it, how do you apply it, and do you use any sort of retarder like mineral spirits or similar to slow the dry time?

I would lay the glue & grit down before priming. I would also thoroughly recommend the anti-slip paste made by AMMO- very simple to apply and can be built up in thin layers.

Work in small areas, a bit at a time with a brush. You can dillute MrSurfacer with Gunze MrColor Thinner but I dont find it necessary.

The good thing with this technique is that you sprinkle the grit and then shake off the excess. If you have gaps left just add surfacer and sprinkle again. You can even do this after priming the model to correct your mistakes.

You can also remove any excess by scrapping with the tip of a blade or something similar.

It is a timely procedure but I find it forgiving and easy to get right.

2 Likes

It looks a bit thick on the close up of the turret. In real life, it’s only around 1/16th an inch, or a mm or two. At least on M-1s

Unless the shading is making it pop that much. Or the painting on top helps soften it, then my apologies.

Yes it’s a very thin styrene cement that the rough medium then sticks to, it’s very forgiving and I had no issues with it although I was very careful where I painted the cement to make sure I didn’t go over an detail. Here are a couple of pics of my finished build, the texture is clearly visible.

1 Like

IDF antiskid tends to be a bit more coarse than the one the one seen on most NATO tanks. If I recall correctly it is made from basalt.

I thought that might be the case!!

Thanks for the advice, all. Time to bust out some scrap styrene and try the other techniques. Definitely going to try Mr. Surfacer; though thinned white glue adheres just fine.