My approach to cleaning up the mold seams and sprue attachment nubs from small and or delicate parts is to use a sequenced removal of the part from the sprue, using the sprue to hold the part (and often serve as a handle).

So, I’ll “rough cut” the sprue apart from the larger “tree” with the part still attached to it. While still held and supported by the sprue, I’ll scrape and sand the mold seams all the way around the parts (except for the attachment points, of course).

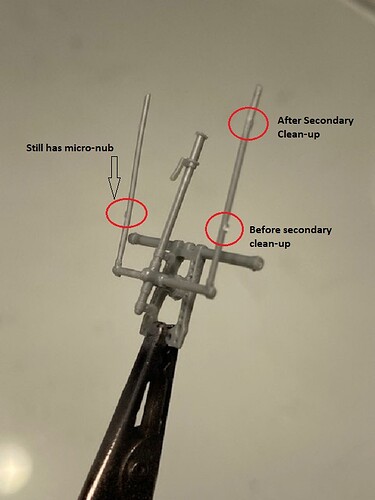

Then, starting away from the area of the part that has the largest cross-section (that, is, starting with the SMALLEST most delicate cross-section, if there is one), I’ll start cutting the part from the sprue (often sawing it rather than using nippers to mitigate force on the part). I’ll do this progressively, one sprue attachment point at a time, cleaning each one up before moving onto the next one.

I use the sprue to support the part and to give me something to hold onto (especially for very small parts). For the very last attachment point, I’ll use a sharp X-acto knife and trim the nub until the last bit of sprue falls off. This usually leaves only a very small “bump” for final clean up from the most robust area of the part possible.

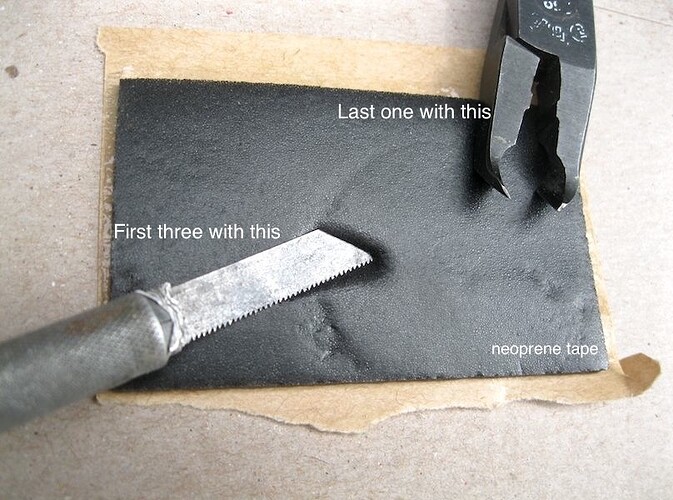

A lot of time, for very thin, long and delicate parts, the main sprue tree, itself, needs relief cuts made to allow the part to flex easily away from the (especially) first attachment point planned for cutting. If this is not done, there’s often a risk that the part will not be able to flex between the attachment points without breaking.

So, my advice is to use the sprue and sprue trees as supporting and holding fixtures and to never hesitate to just cut the whole big sprue up to mitigate unwanted stress on the parts are they, themselves are cut away from it.

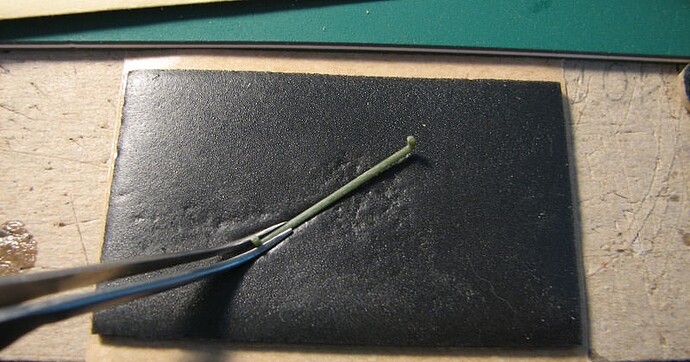

I hunted around through my build photo folders to see if I had a good picture of what I tried to describe, above, but the best that I could come up with was this one:

This picture shows some work I did to modify the Tamiya’s M13/40 kit road wheels. Here I left the wheels attached to the sprue while I routed / thinned their reverse sides and drilled the lightening holes all the way through them. The sprue served as a convenient handle to hold the small wheels for the work. I also cleaned up the mold seams before I cut them away from the sprues leaving only the nubs to clean up.

I handle most small and delicate parts like this (even though these wheels wouldn’t be considered particularly delicate). The kit sprue can serve more purpose than just holding the parts in the box or providing scraps for heating and stretching.