Hi folks.

In my quest to cull the WIP list (scary as it is) this year, I dragged out this kit that I started back in 2017.

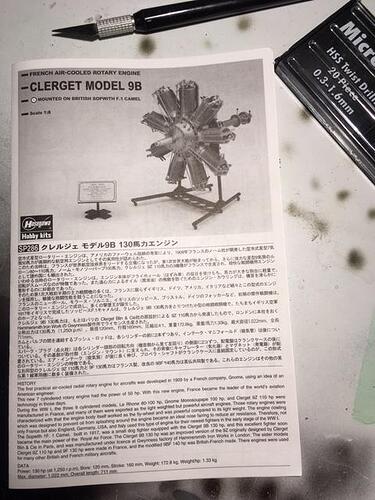

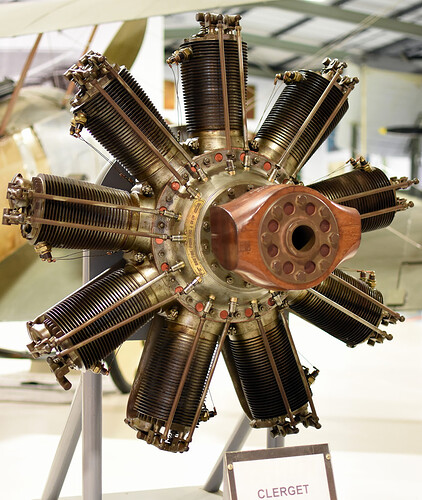

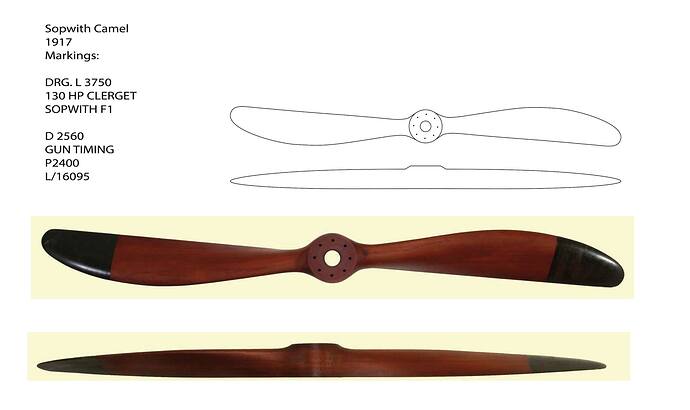

There was a build thread started on the old Aeroscale site AeroScale :: Sopwith Camel Clerget Project, and this kit was also the subject of my first review on Aeroscale AeroScale :: Hasegawa Models 1:8 Clerget 9B Rotary Engine Review.

I have made some progress over the past couple of weeks, but I thought I would summarize the original thread here to get things rolling.

Saturday November 4, 2017

Step 1, open bottle of Johnny Walker Blue Label and pour over ice.

Step 2, reacquaint myself with tool kit.

Step 3, read instructions and fondle sprues.

Step 4, get amongst the styrene!

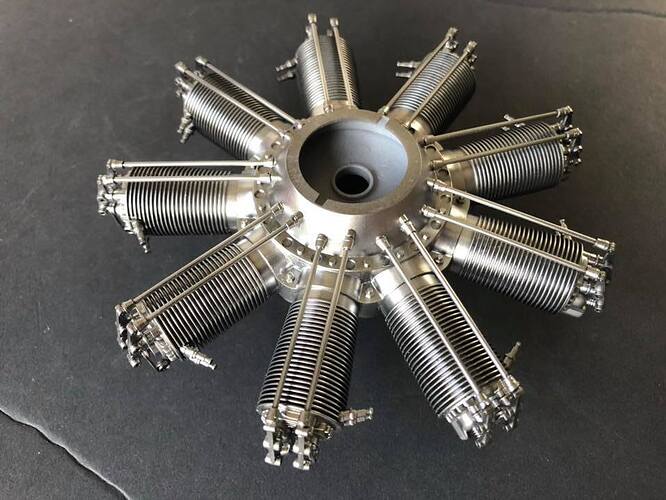

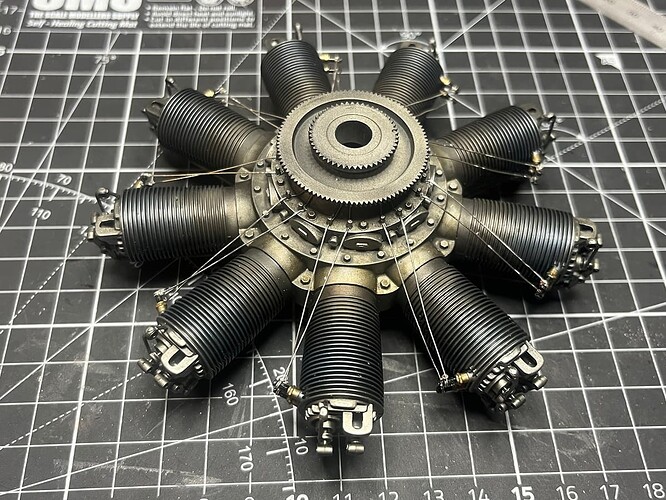

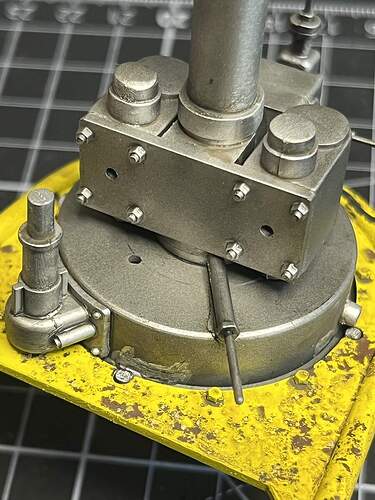

Stages 1 and 2 completed:

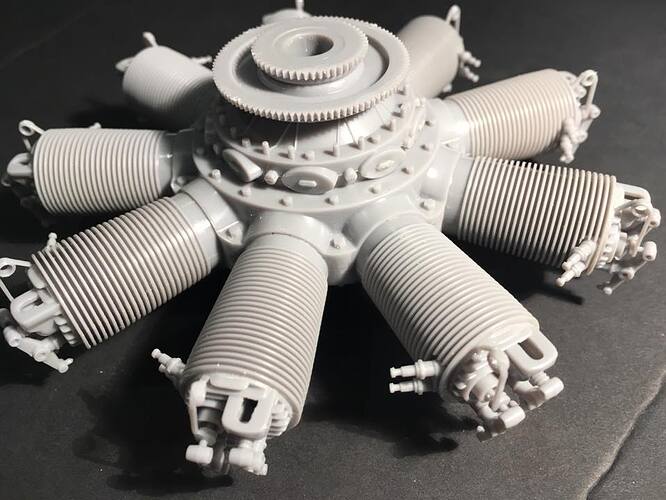

Part number A4 is very fragile. I managed to break 3 of the 9 pieces while removing them from the sprues, but the fix was quite easy.

The detail is very crisp, virtually no flash, and the fit is excellent. Very little cleanup or sanding so far.

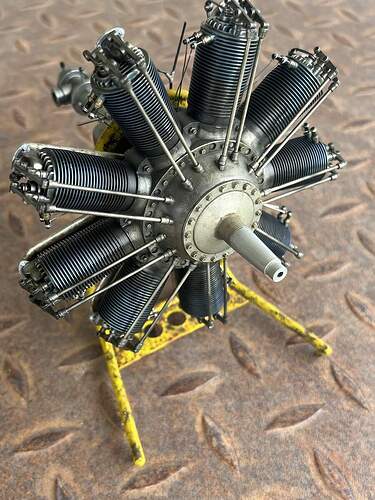

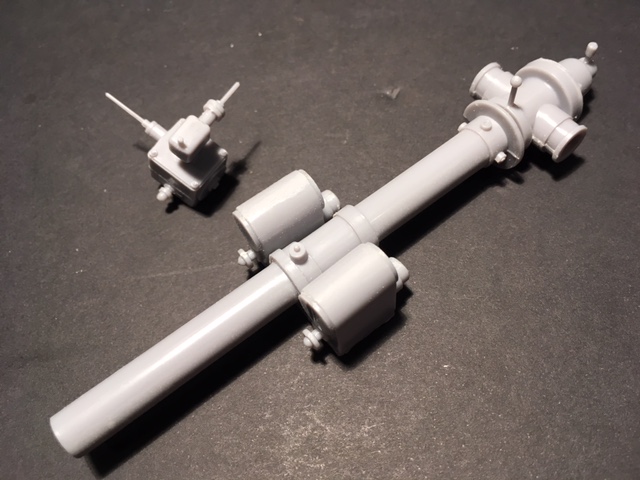

First part of Stage 3 completed, Cylinders assembled to Crank Case. I will paint this stage before I attach the Intake Pipes (to be pre-painted separately).

And for a sense of scale:

Friday November 10, 2017

A little more progress tonight. Some filling and sanding to do once the cement sets up properly, but no major issues.

Saturday November 18, 2017

Hi folks. Some progress tonight, approaching paint stage now!

18 brass rods and 36 collars

Add some CA and we have 18 push rods. Collars will be cleaned up once the CA is cured fully.

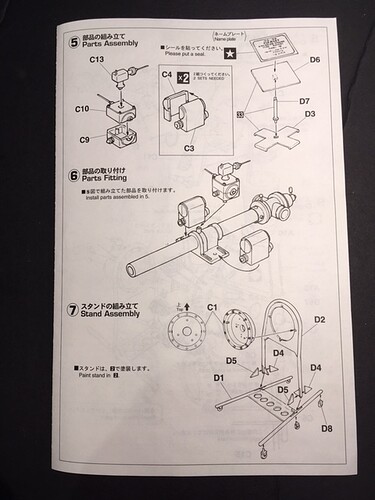

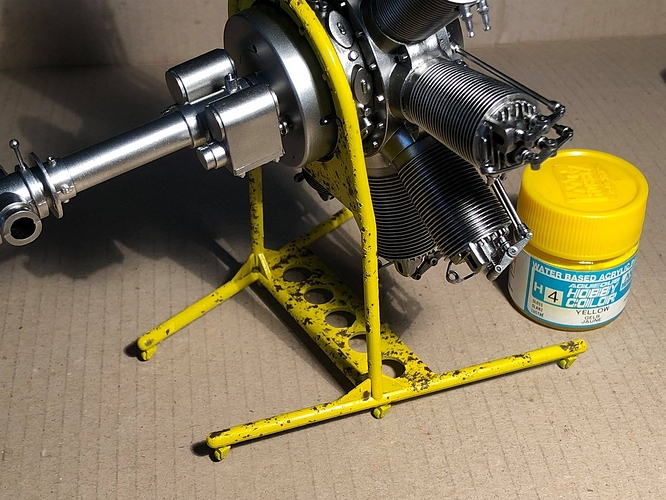

Engine and Label stands assembled.

Detail on the engine stand right down to the casters is great!

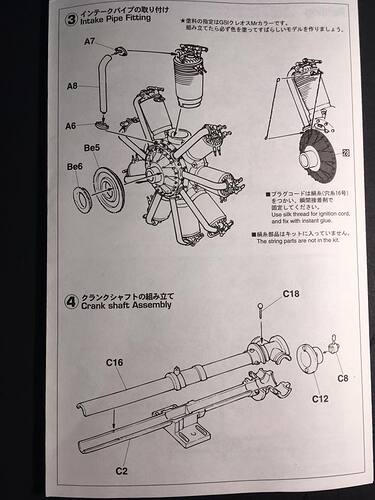

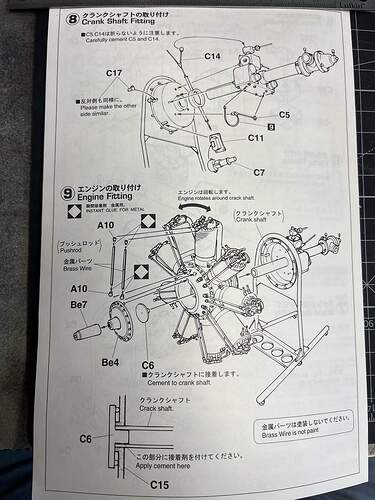

Found a small error in the instructions, in step 7 parts D4 and D5 need to be reversed, they are slightly different sizes and the channel in the frame base is a very neat fit specific to the correct part.

Tuesday November 21, 2017

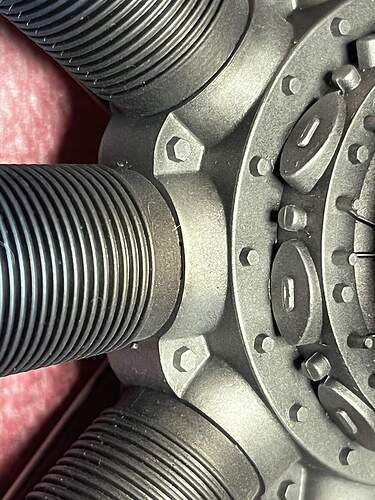

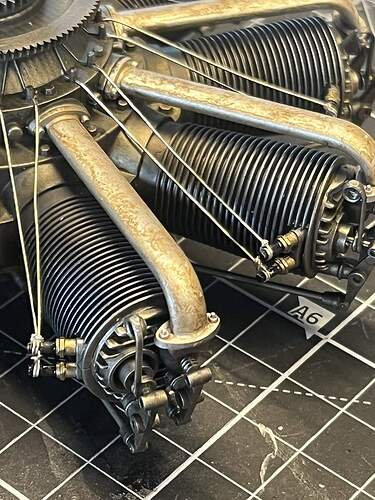

Time to fit the push rods. Some points to note, a bit of trimming work is required here.

As the brass rod pushes most of the way through the collar, I found it necessary to cut off half of the length of the locating pins on the rocker arms (circled 1), I used my sprue cutters.

Each cylinder has an inner and an outer push rod, and in order to get a neat fit of the bottom collar on the inner push rod I had to chamfer the bottom of the collar (circled 2).

In most cases the push rod is slightly too long so I trimmed the length by sanding the ends to prevent too much stress on the rocker arms.

Friday November 24, 2017

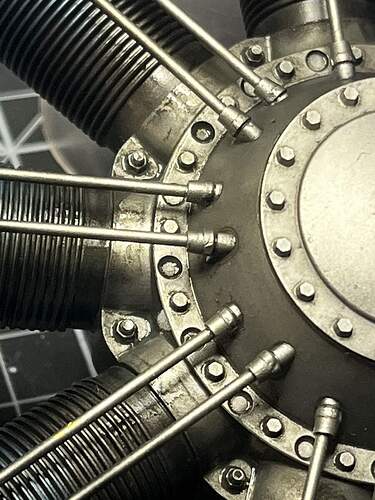

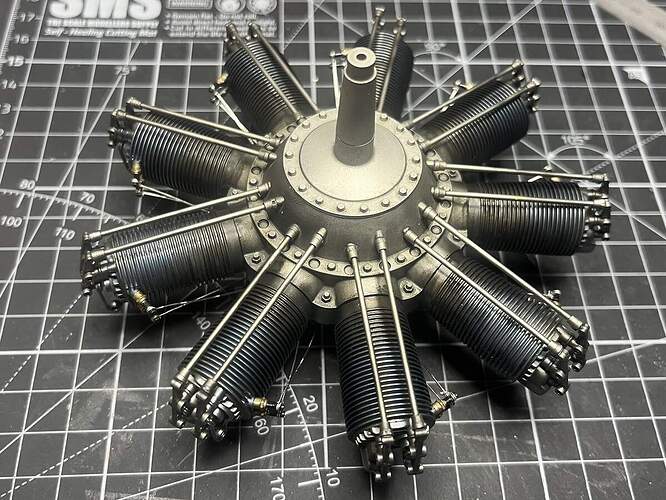

Push rods all fitted last night.

Time to get the rat-tail files out and do some clean up of mould lines and seams, then time for paint.

Cheers, D