Hello model builders,

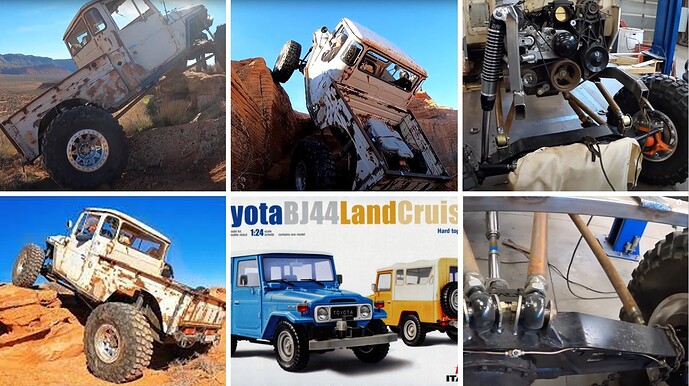

Just after I finished kitbashing a Chevrolet Canopy Express and then making it into a four wheel drive, I decided I had at least one more of these in me to build. This time though, basing the build on a truck built on a youtube channel called Fab Rats. I didn’t do this to begin with because I didn’t think there was a Toyota Land Cruiser available - well, there is - so below you’ll see the inspiration and the kit from Italeri:

The guy on the channel built this FJ45 up using a dana axles, four link front and rear, NP tranfer case, doubler, and Chevy LS engine. After the last build, I opted out of the LS engine work. There is a really nice kit avail but it’s sort of expensive, and will never be seen.

Instead, I went with a junkbox Chevro_For_Dodge V8 - that is various parts assembled so that I could attach a transmission, scratch build a transfer case, and have visible headers.

I then stopped work on it for several months. Friday, I decided to get after it again, and here we are:

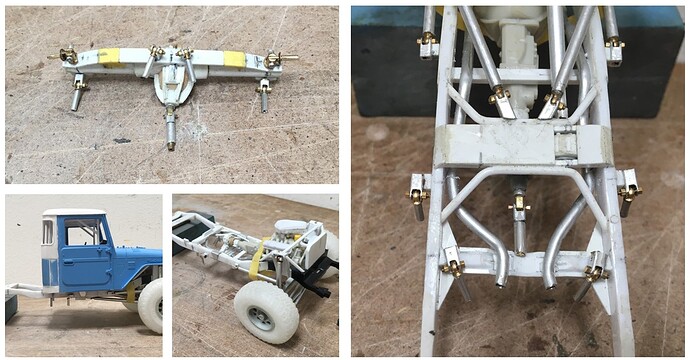

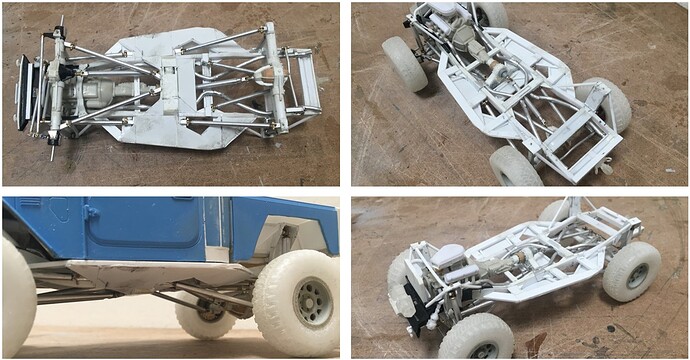

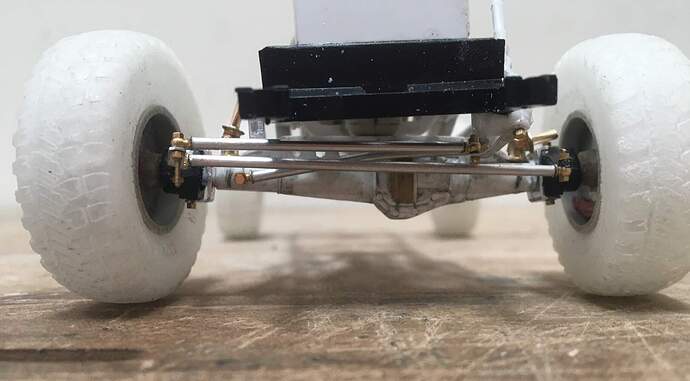

As you can see above the chassis (another mix and match, including the very front off the Toyota, scratch built/kitbashed Dana axles with trusses, and body work was about done.

Over the last couple days I added the mounting hardware for the four link to the frame and rear axle. This includes the use of several segments of brass rod and square tube, aluminum square tube and lots of tiny hardware. The latter of which I ran out of, and while it is indeed some sassy hardware, it’s expensive and not always easy to find, so I went about scratch building connectors using brass rod and alu tubing - just as good and a lot less expensive - you can see this on the rear axle, where the single and double clevis’ are tied together for shock mounts.

And below, what it looks like assembled:

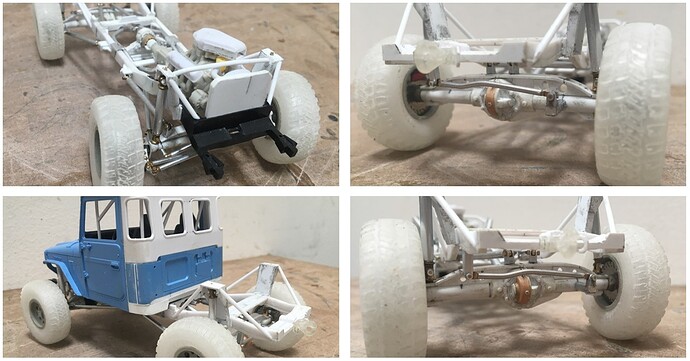

This works out to be a posable four link suspension front and rear. On one hand, the four link might look relatively simple - which it is in some ways, but, if the geometry is off, well, nothing will be aligned correctly - the clocking of the axle, centering of the axle, or the ability for the whole setup to flex as intended. There is a fair amount of experimenting to get this to work correctly

For a test, see below:

As you can see, albeit dryfit, and with no rear shocks and on and on, it works! The object of this type of suspension is to allow all four wheels to remain on the ground, despite what can be dramatically uneven surfaces.

Next up will be to finish the rear end. I built a cage for this early on, and despite never being seen again, a stick shift, transfer case lever, doubler lever, steering column and highly modified transmission tunnel are in there -

Thanks for having a look

Cheers

Nick