I have a Special Hobby 1/48 Focke-Achgelis helicopter. I’ve had it my stash on a back shelf because of a cracked canopy. I’ve tried for a replacement part without success. The canopy isn’t in two pieces, but the crack is extensive and goes all the way through. There are always suggestions to glue the crack and polish it - that will only repair the surface, but the crack will still be visible in the depths of the plastic. Is there any solution to make the crack disappear, or to diminish it? I would like to someday finish the model.

![]()

![]()

Can you repair the crack with liquid cement, polish out the joint and use the canopy for a master to vacuform a new one ? Or use it as a plug for a silicone mold and cast one in clear resin ?

- I don’t have a vacuform, and don’t know anyone who does.

- I really don’t want to shell out almost 100 CAD for molding and casting supplies. Used to dabble in casting my own, and eventually got expensive.

- I’m looking for a cheaper solution. Maybe just glueing and polishing, and ignoring the crack.

Honestly this is what I’d do since you’ve already tried to replace.

And maybe tinting will make it less noticeable.

I bet someone on this forum has a vacume form machine. If you repaired the windshield and made a mount for it, they might make you one if you sent them the wind screen.

Could you make it into battle damage or other service related damage?

There are cheap sets to repair real windshields using UV liquid transparent resin, and sometimes the result is amazing, making it completely disappear. They do not glue but fill the crack -I am not sure that gluing it will solve your problem.

You may try to crack an old spare transparent part and see how any of these solutions work, before risking the good one.

The problem with using a windshield repair resin is that these work because they are formulated to have the same refractive index as windshield glass, so there’s no visible discontinuity where the crack was – your recommendation to try the repair using a ‘waste’ part is a good one, but I think the crack line will still be visible afterward.

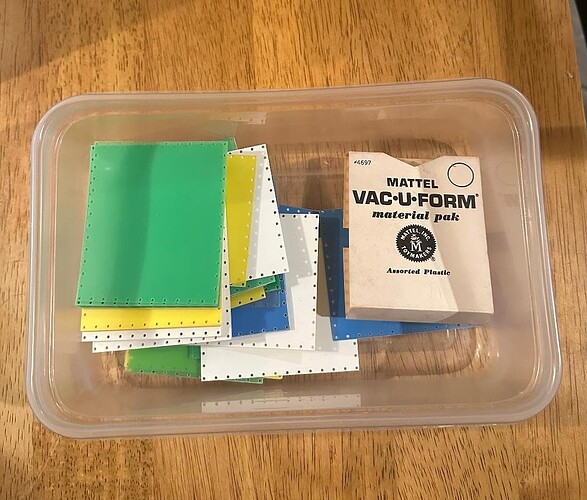

Some of us even have two. You know the old saying: Two is one, one is none.

The good news is you don’t need one. Back in the late 90’s I had a tip published in FSM that showed how to heat form with a machine. I used the curved fenders for the M5 halftrack as an example. I made forms from two part putty mounted on pieces of coat hanger wire. Then I cut a styrene disc to go inside the lid of a mason jar. Heat it in the oven oven it starts to sag on its own. Plunge your form into it. I can see this working for a canopy as well.

EDIT:

I almost forgot. I have a stack of the original plastic sheets as well.

seems like hell to me ![]()

but what you need is glue with the same light refractive index as your cracked frame.

Refractive Index of Polymers and Plastics - Table

assuming your canopy is polystyrene, you would need glue with a refractive index of 1.59. companies like Loctite or 3M. The challenge is to find a glue that will not “eat” the plastic

another tip is to polish the crack before putting the two halves together. I crack is not a clear cut but is rough. The glue will not enter each micro crack, hence it may be helpfull to polish it a bit?

Last but not least, a friend had the same with a F-15 in 1/32 scale. He solved it by putting a cloth over it: