Hello everybody!

Some time ago I got the new Dynamo Models M55 Quad 50 from @Sylvain59. Thanks a lot Sylvain!

I got in contact with NDQSA (https://ndqsa.com/) and I’m building this kit in contact with people who “been there, done that”.

There’s a post about this kit here: Dynamo Models: US Quadmount Machine Gun | Armorama™ - #15 by Stephan

I’ve already built the Dragon kit before and I write about it on my web page: M55 Quad 50 Emplacement Diorama

I’ve also have a WWII-era TM for it there: http://vietnam.net.pl/M45quad.pdf

Since then I’ve found out more about some details and differences between the WWII and Vietnam Quads and I’ll try to incorporate this additional research in this build.

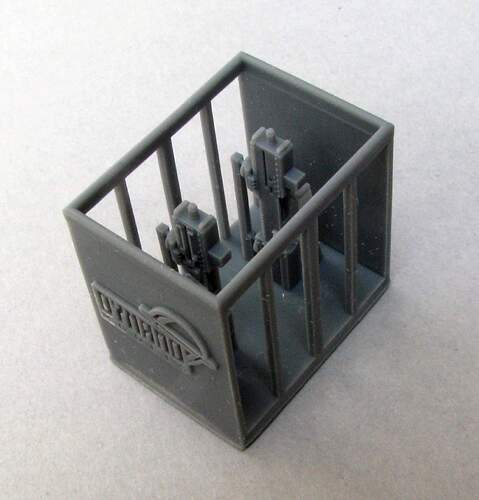

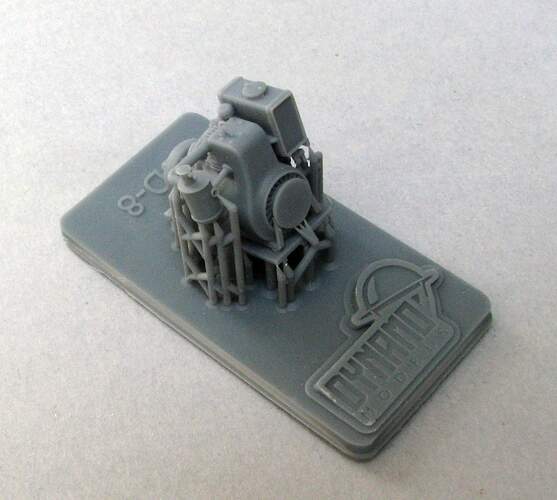

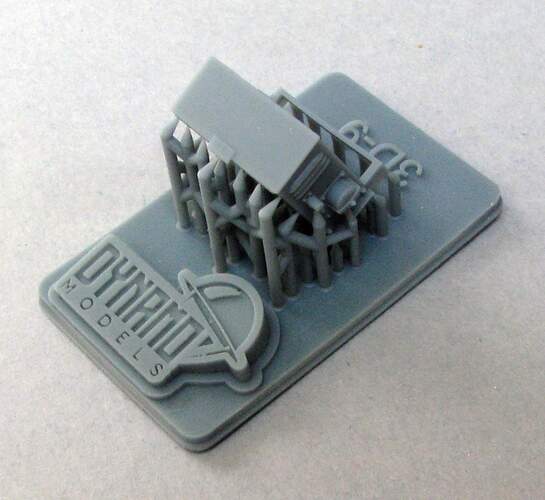

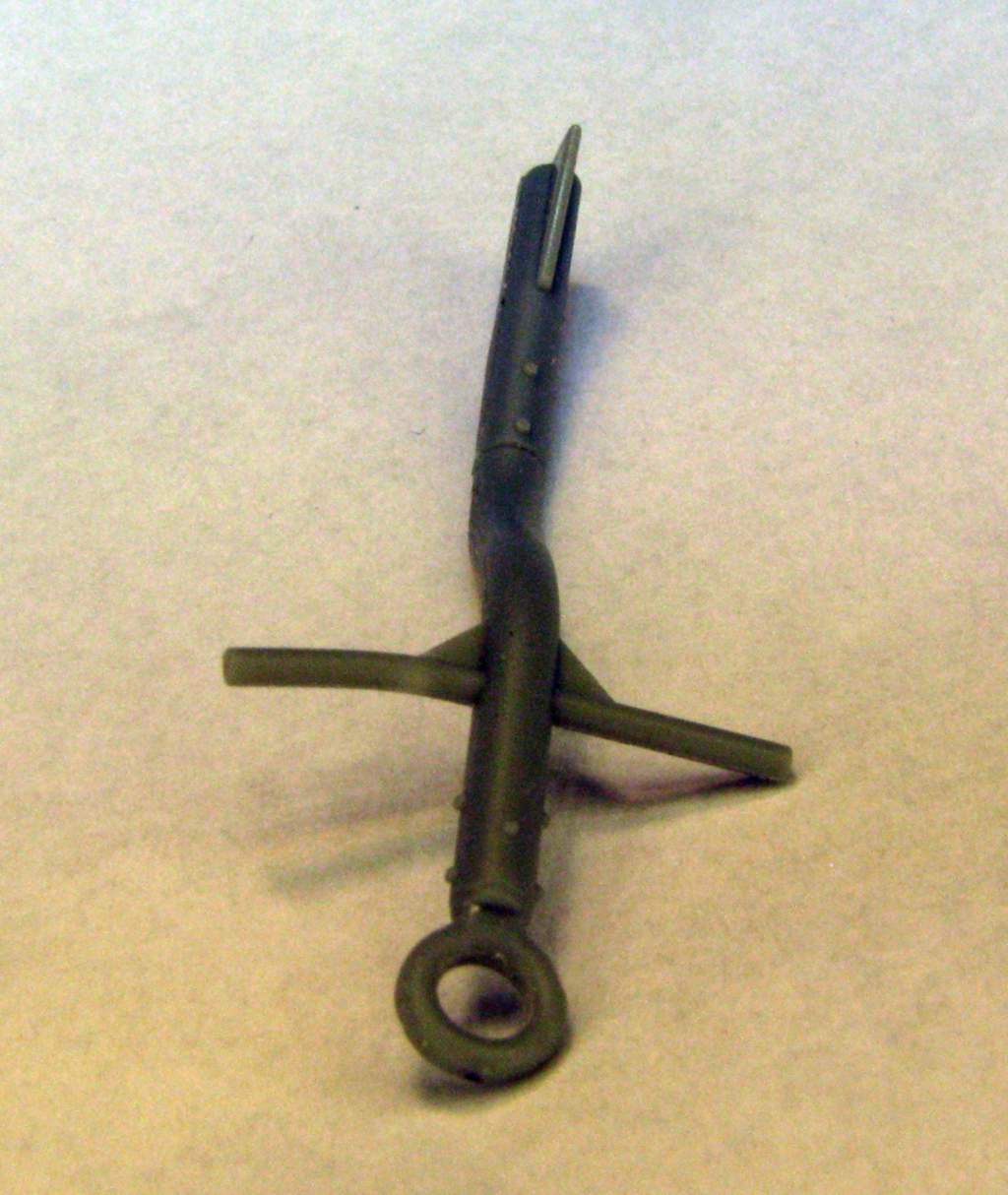

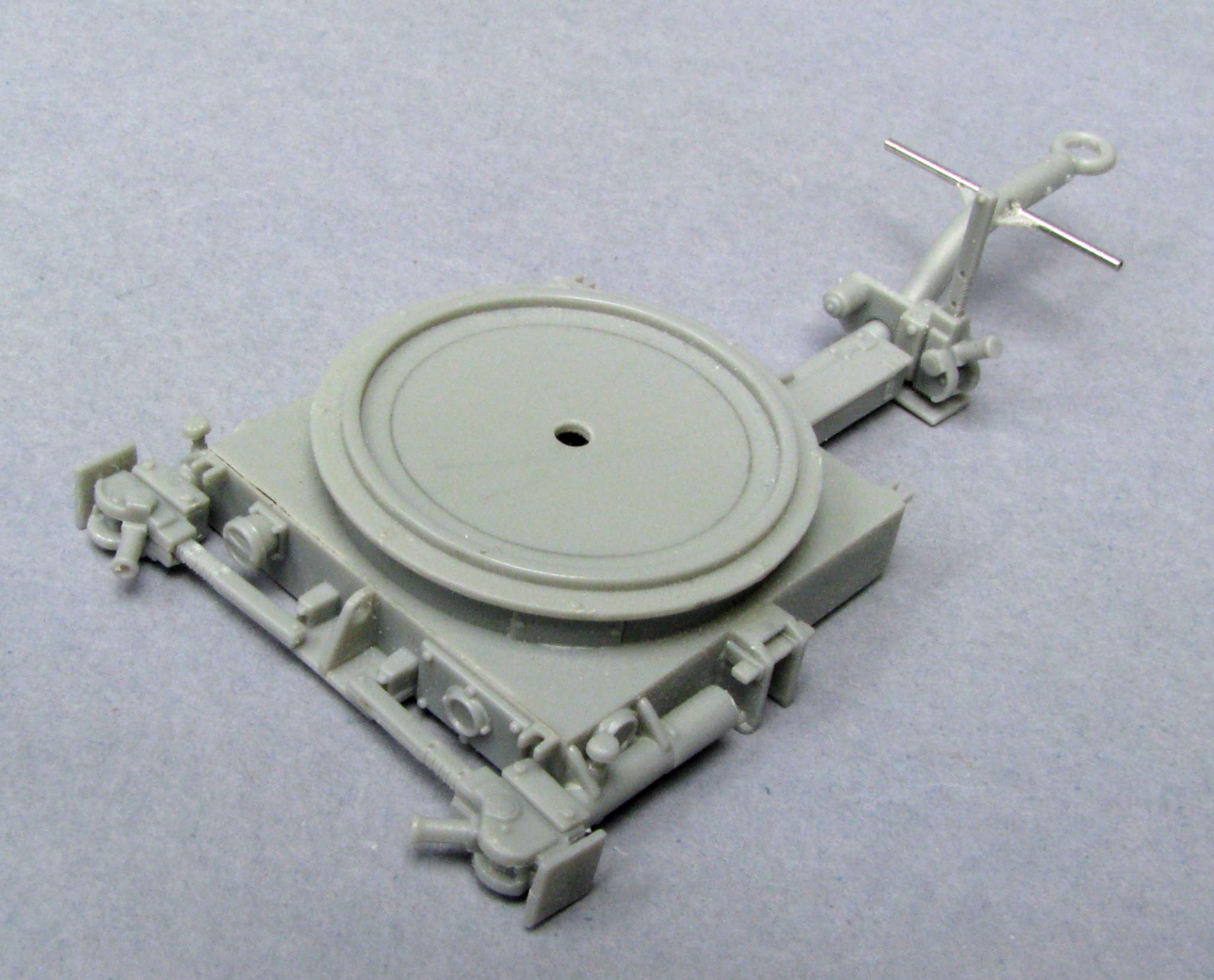

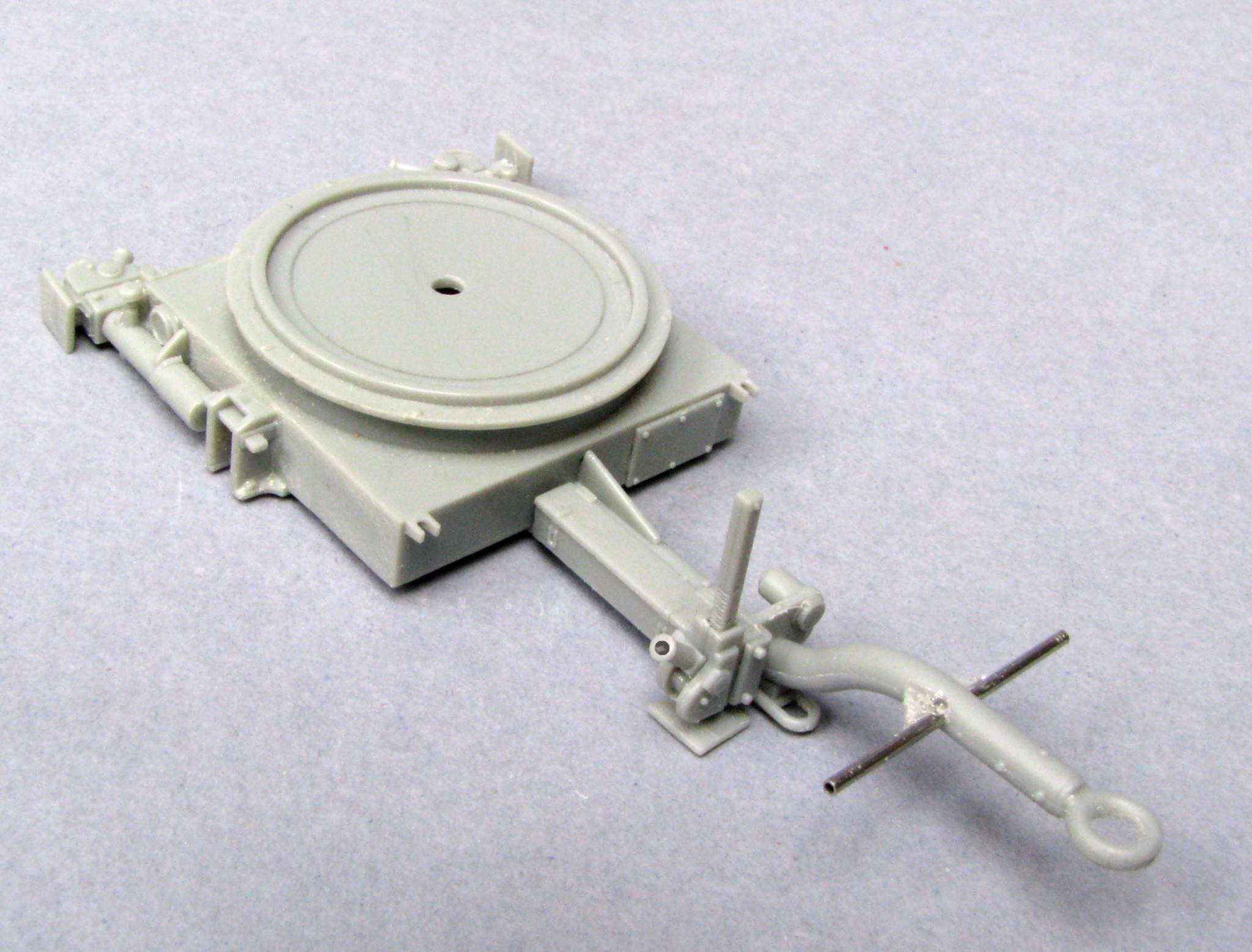

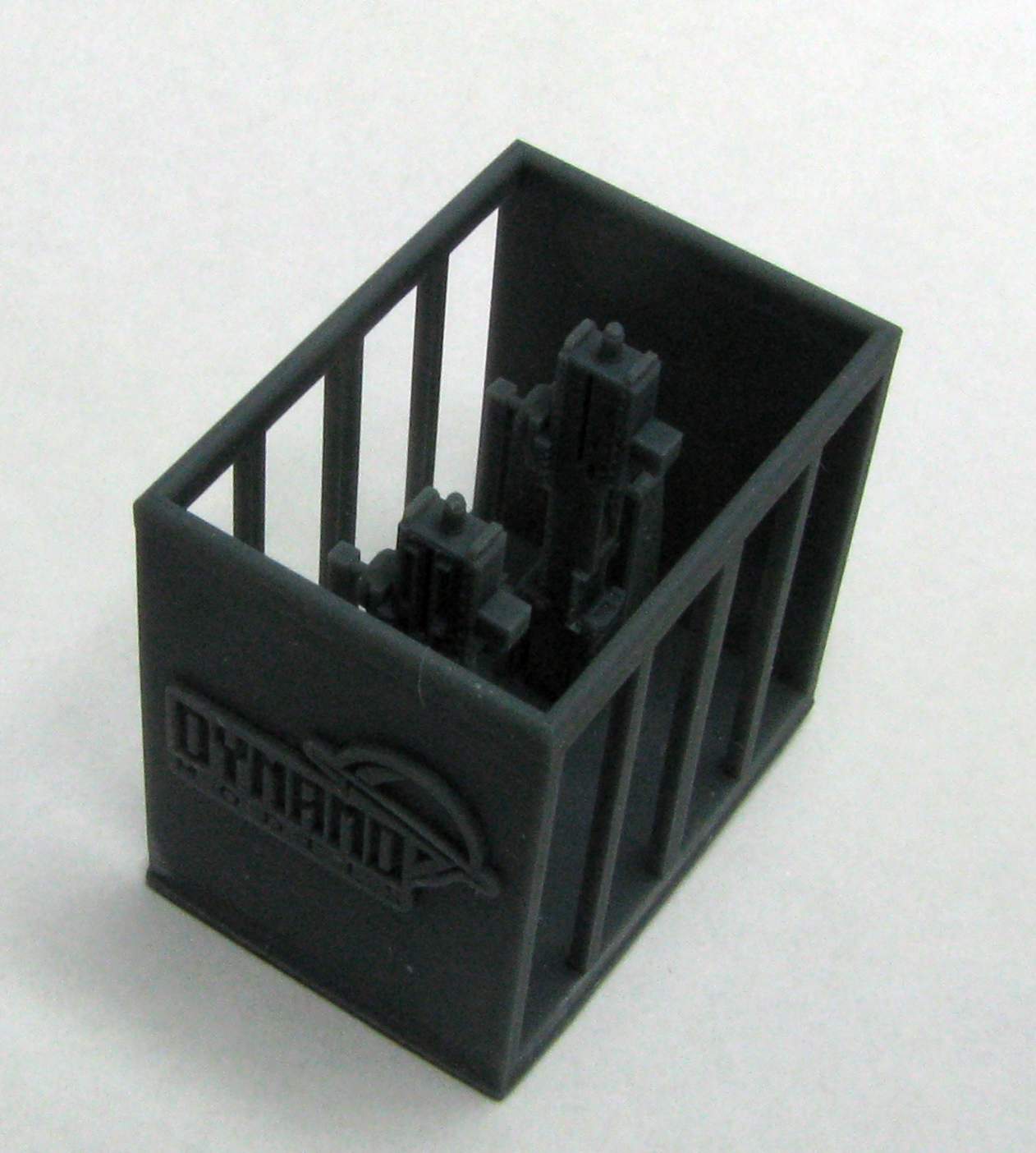

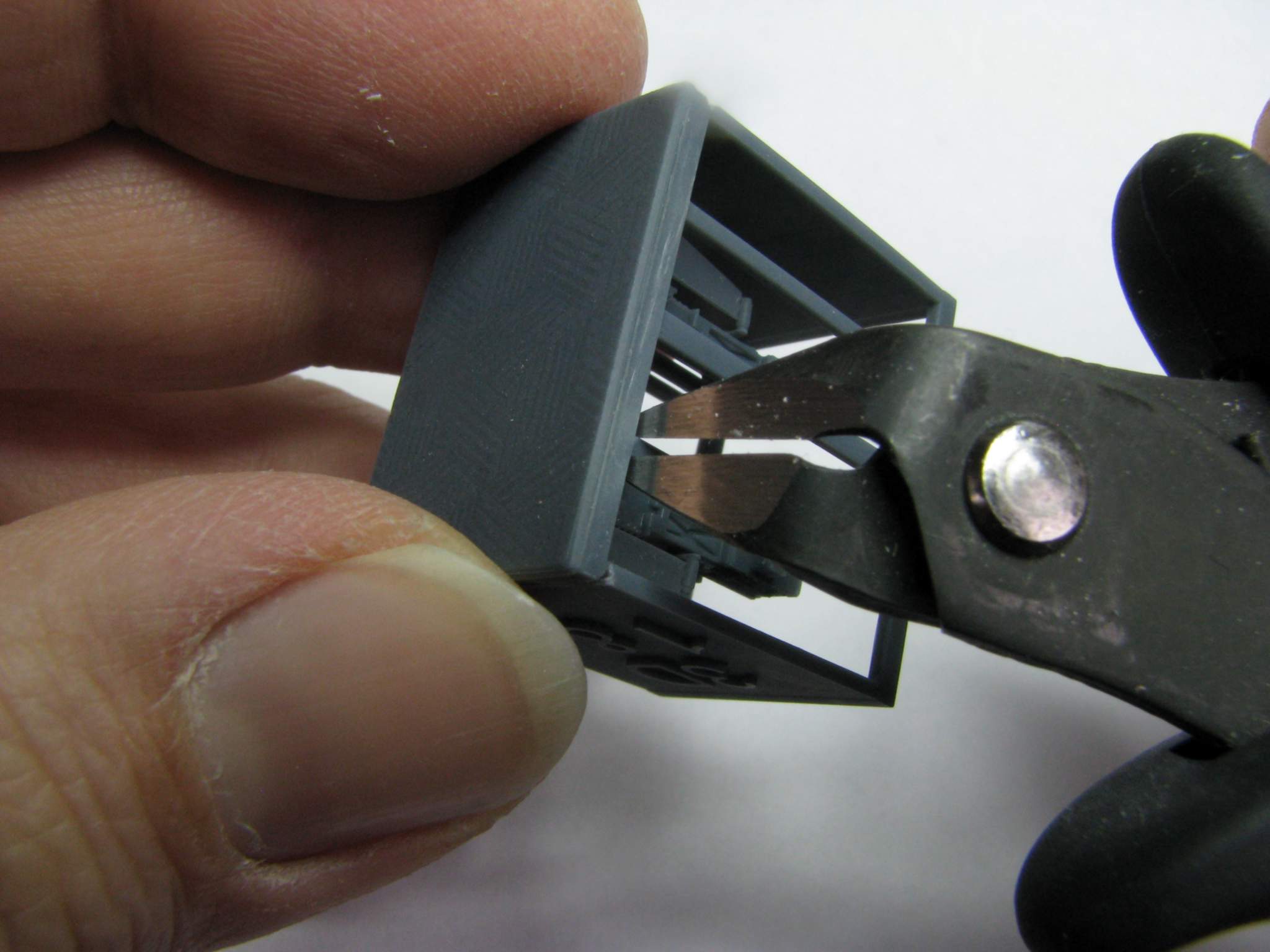

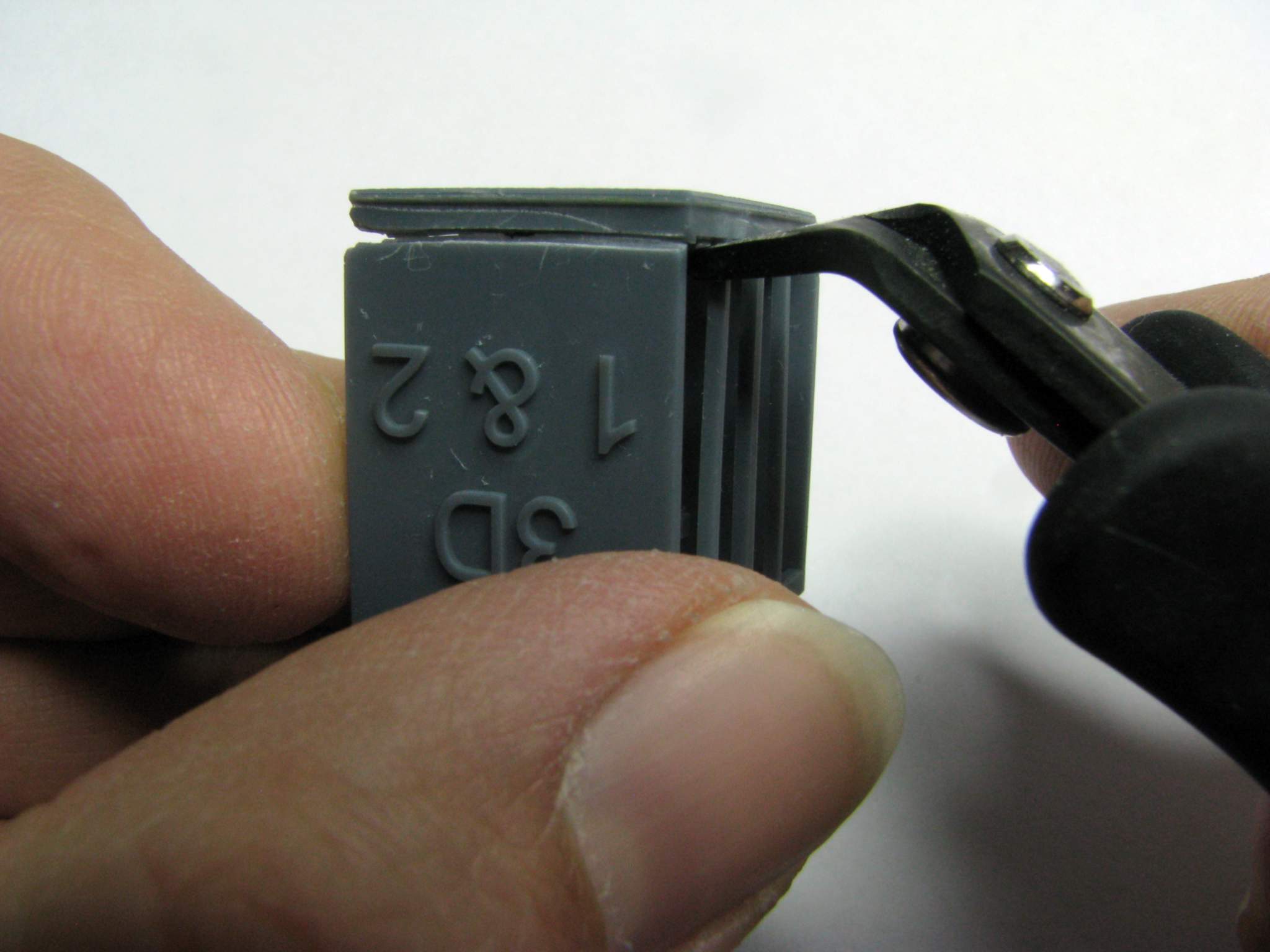

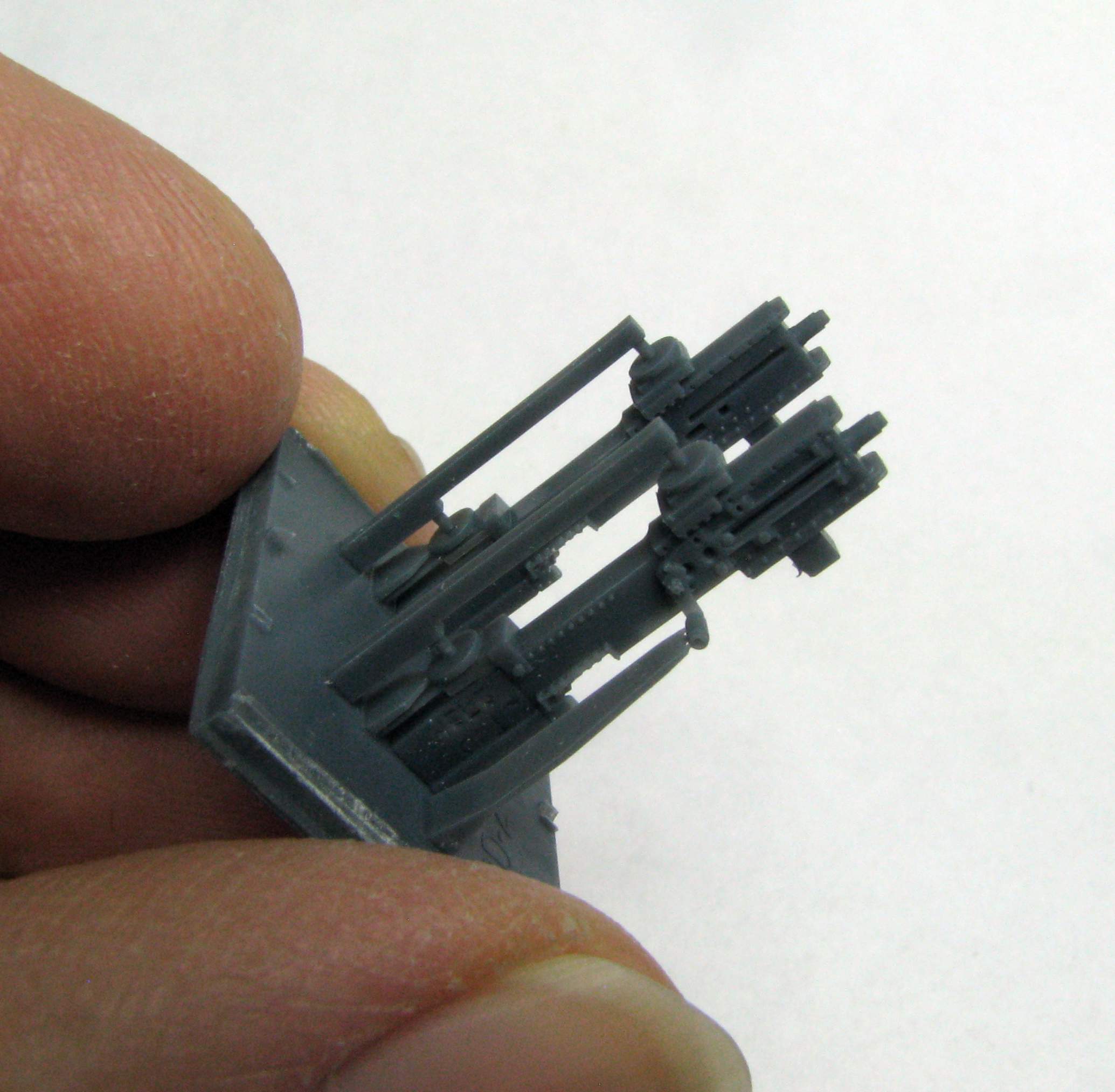

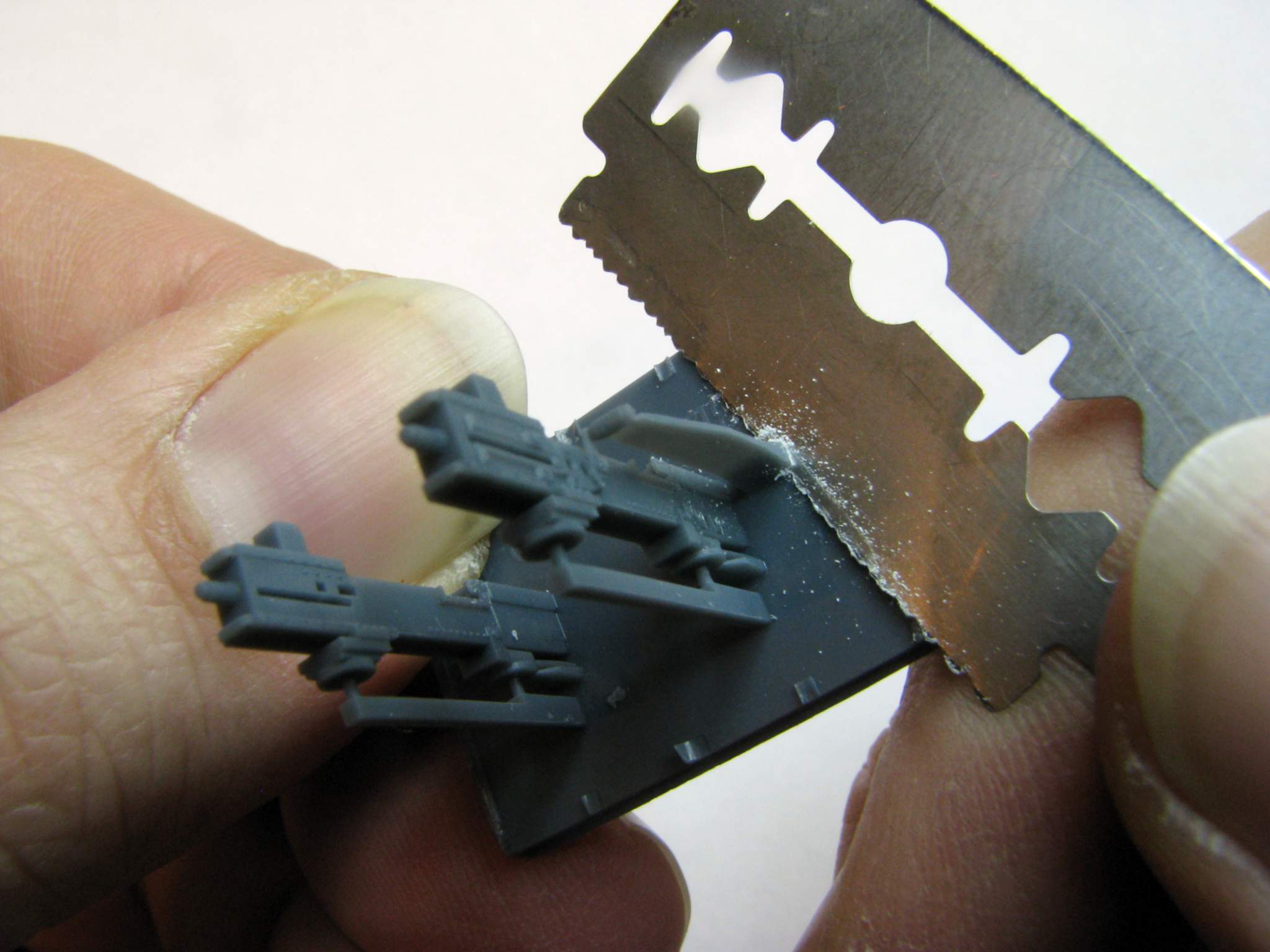

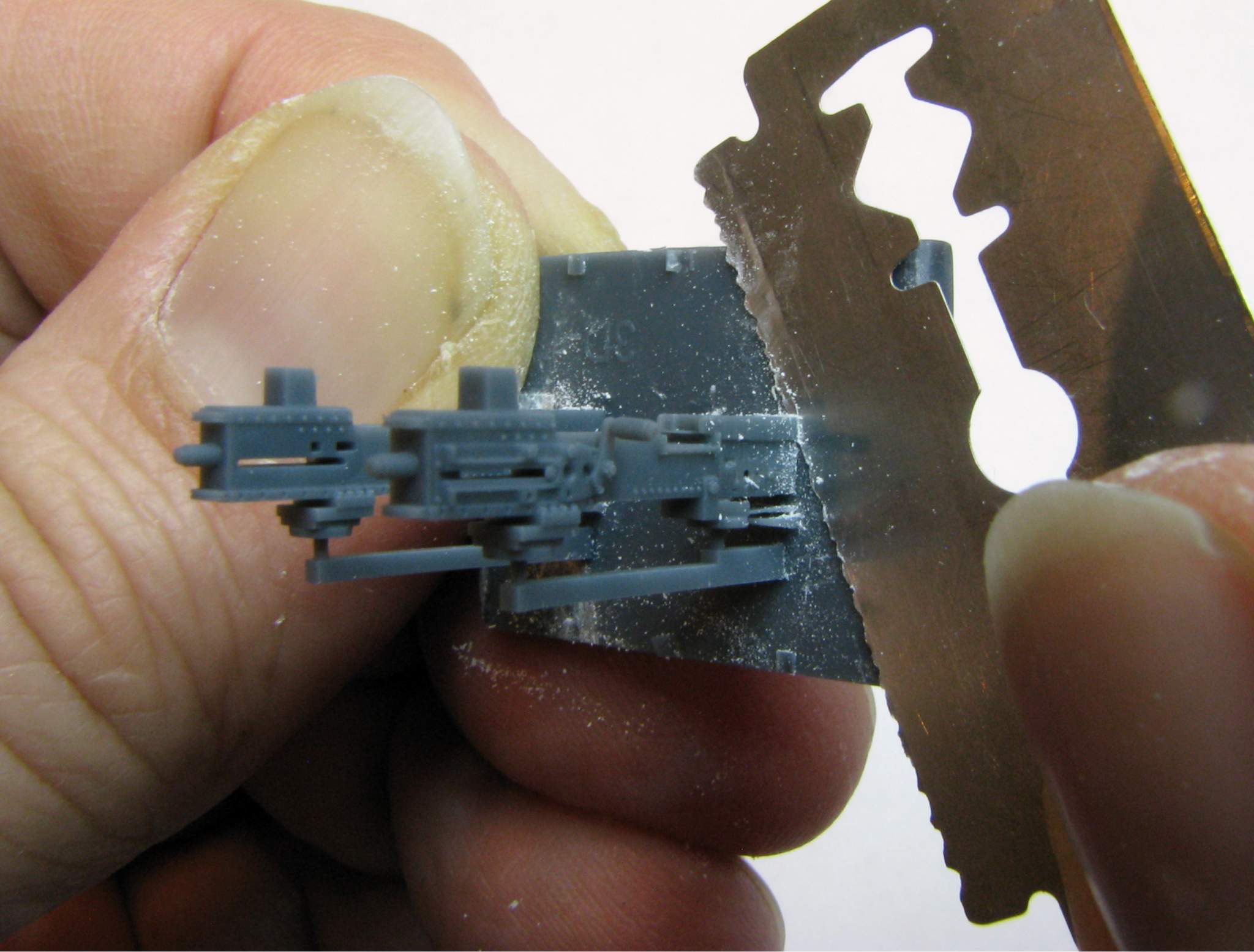

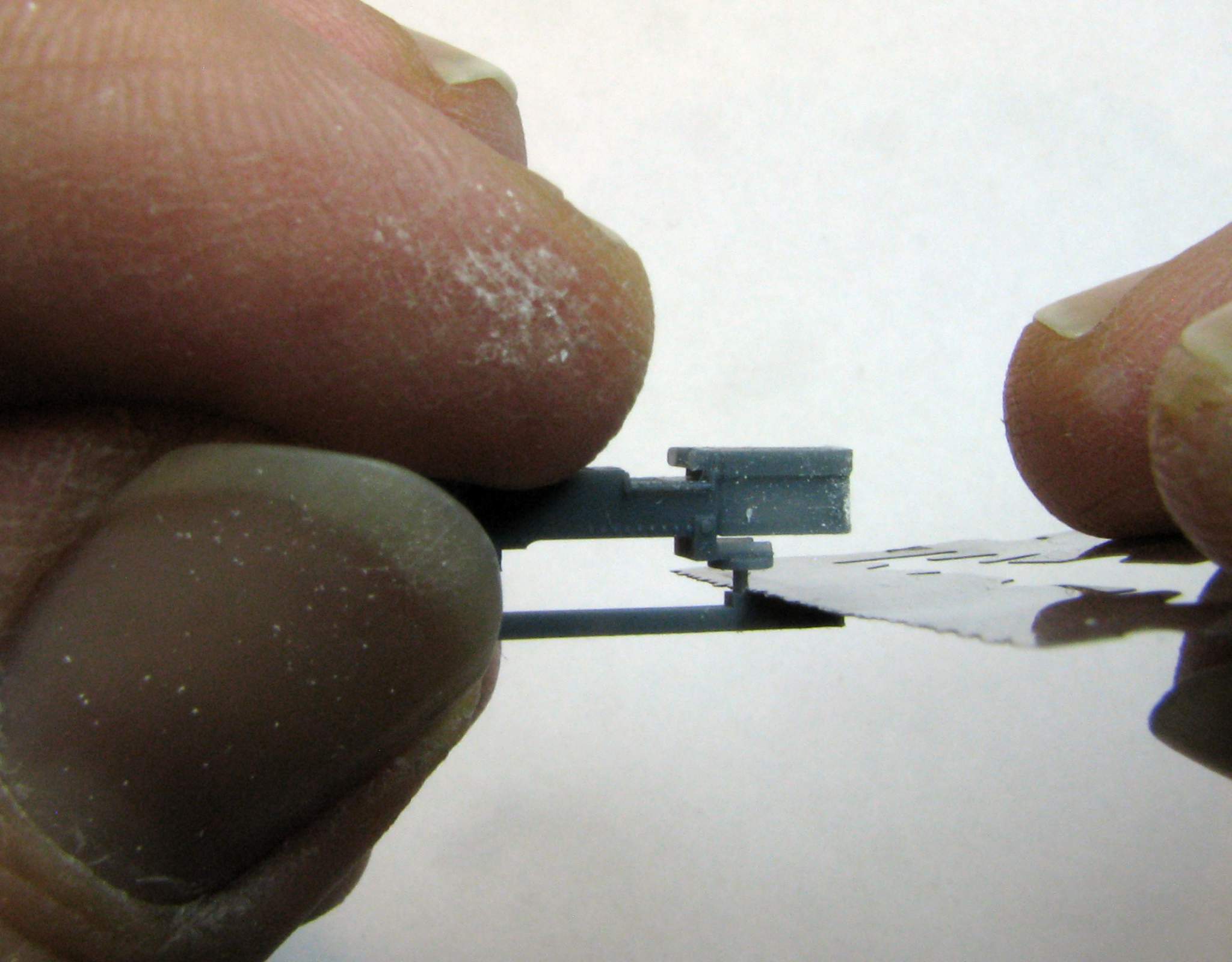

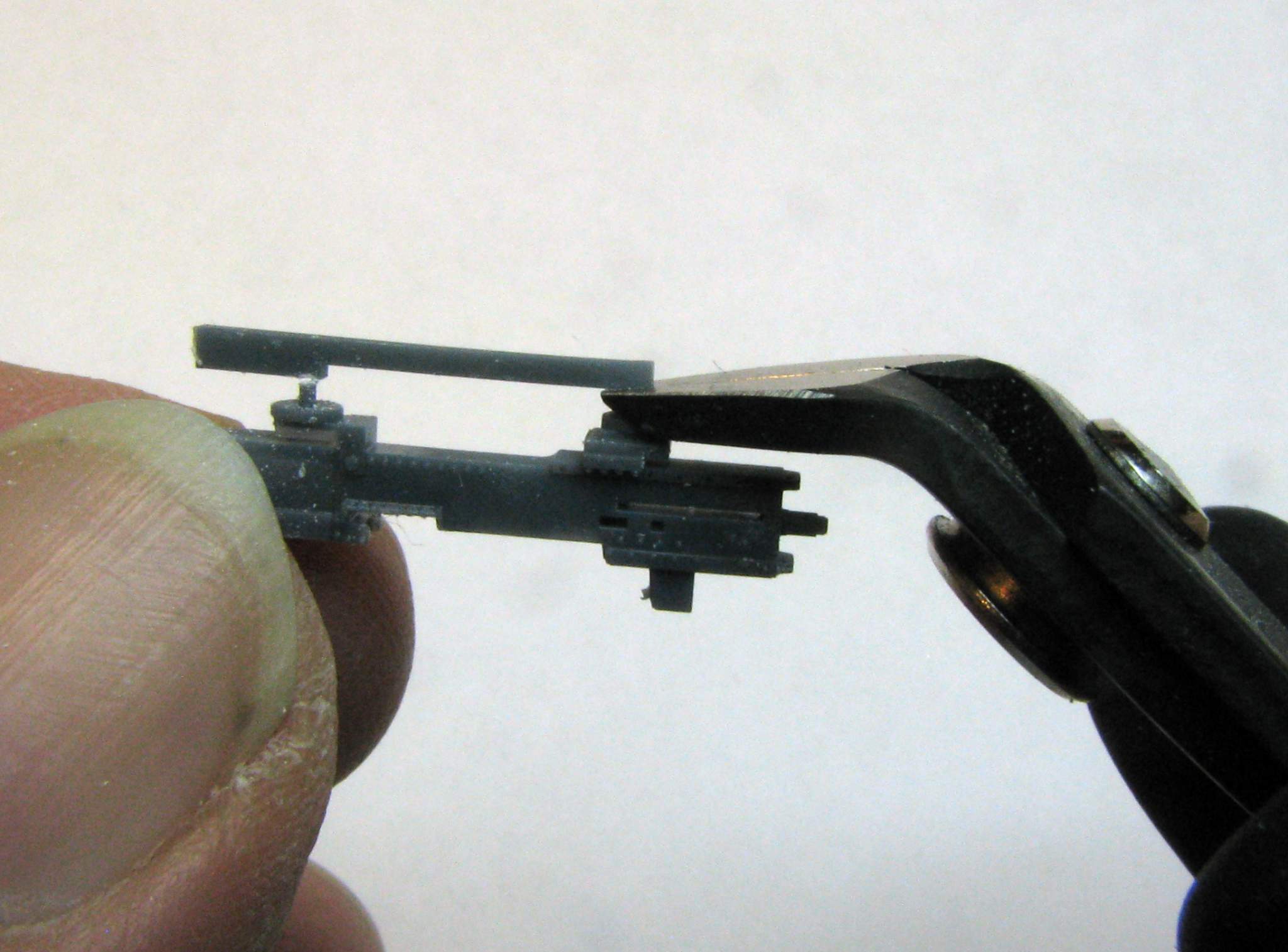

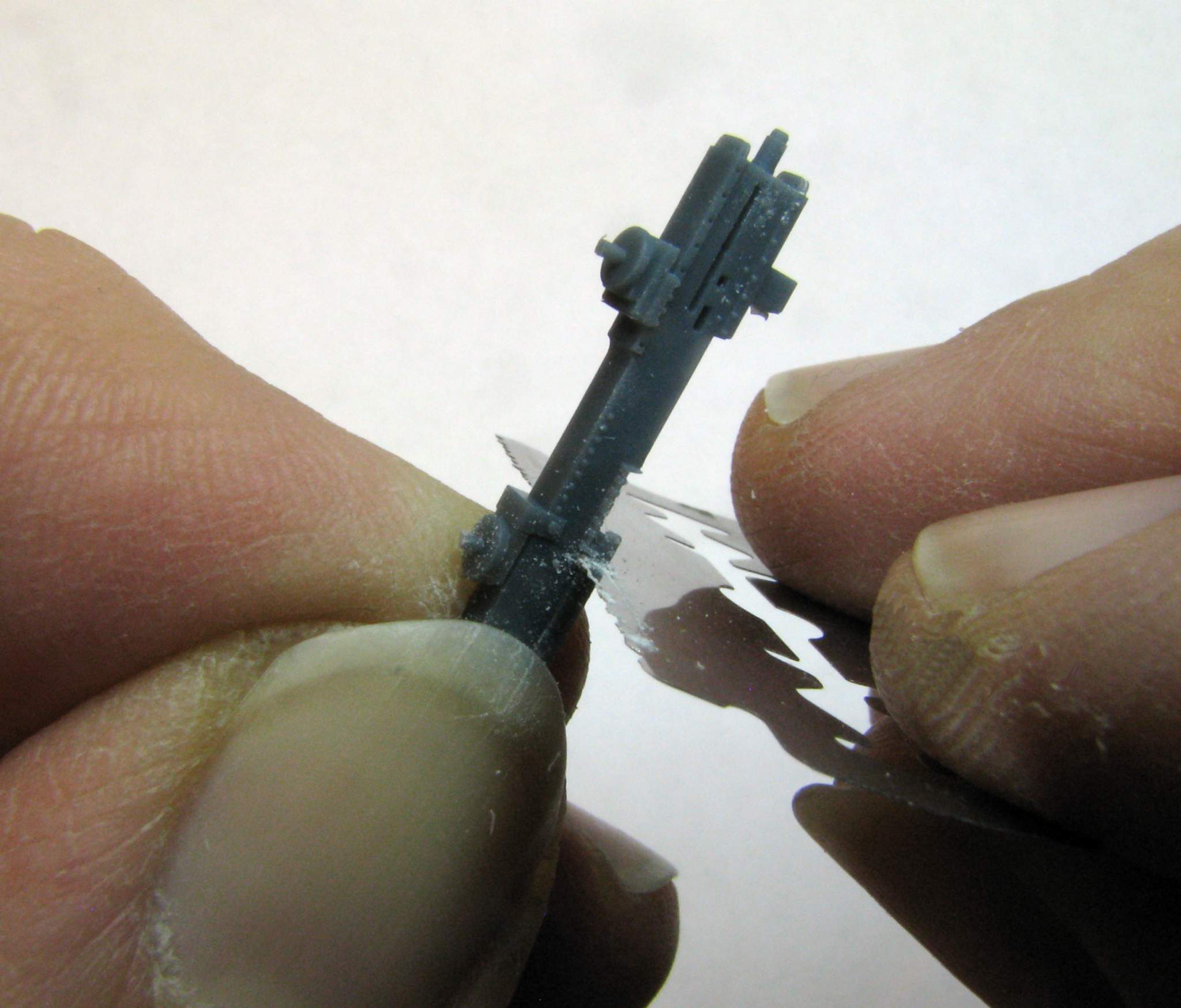

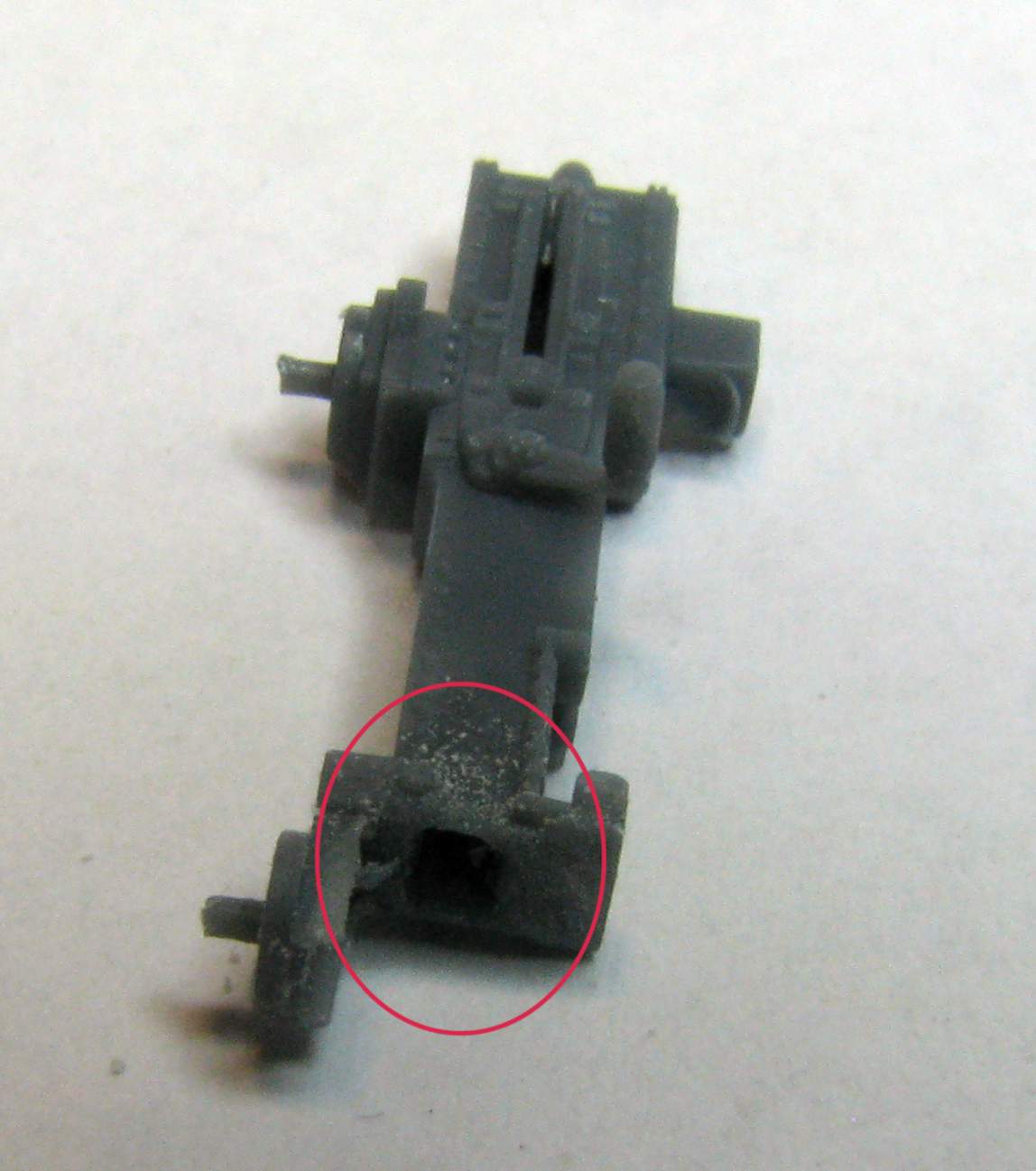

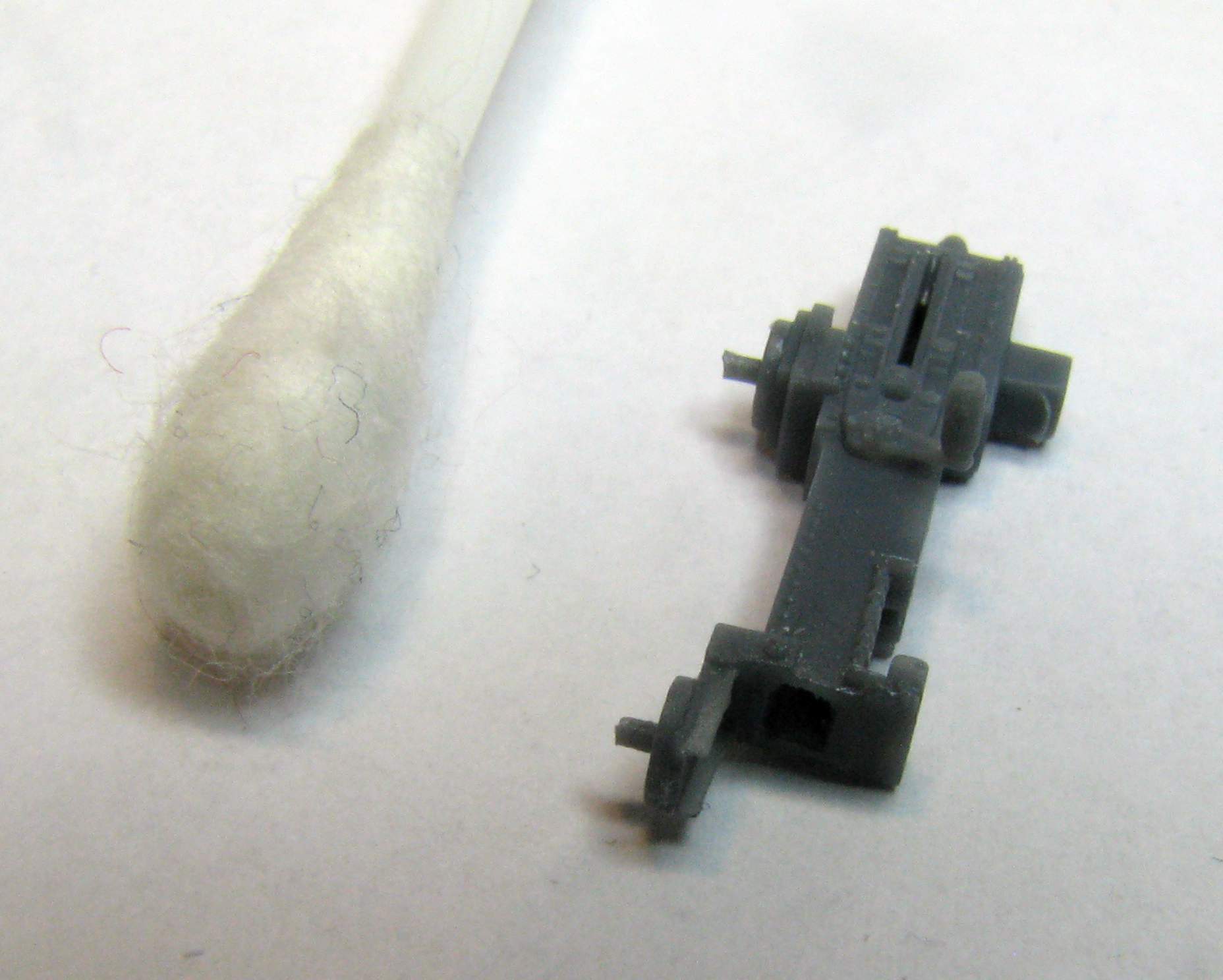

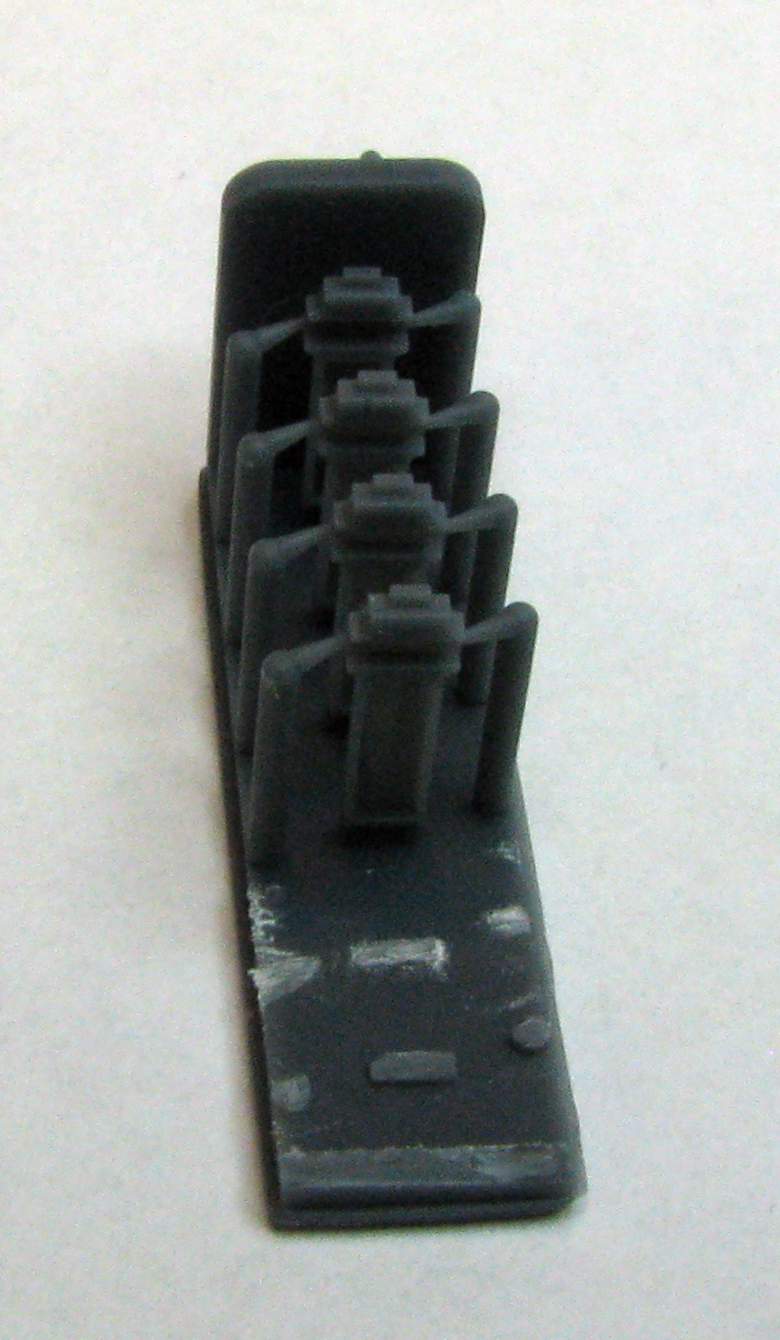

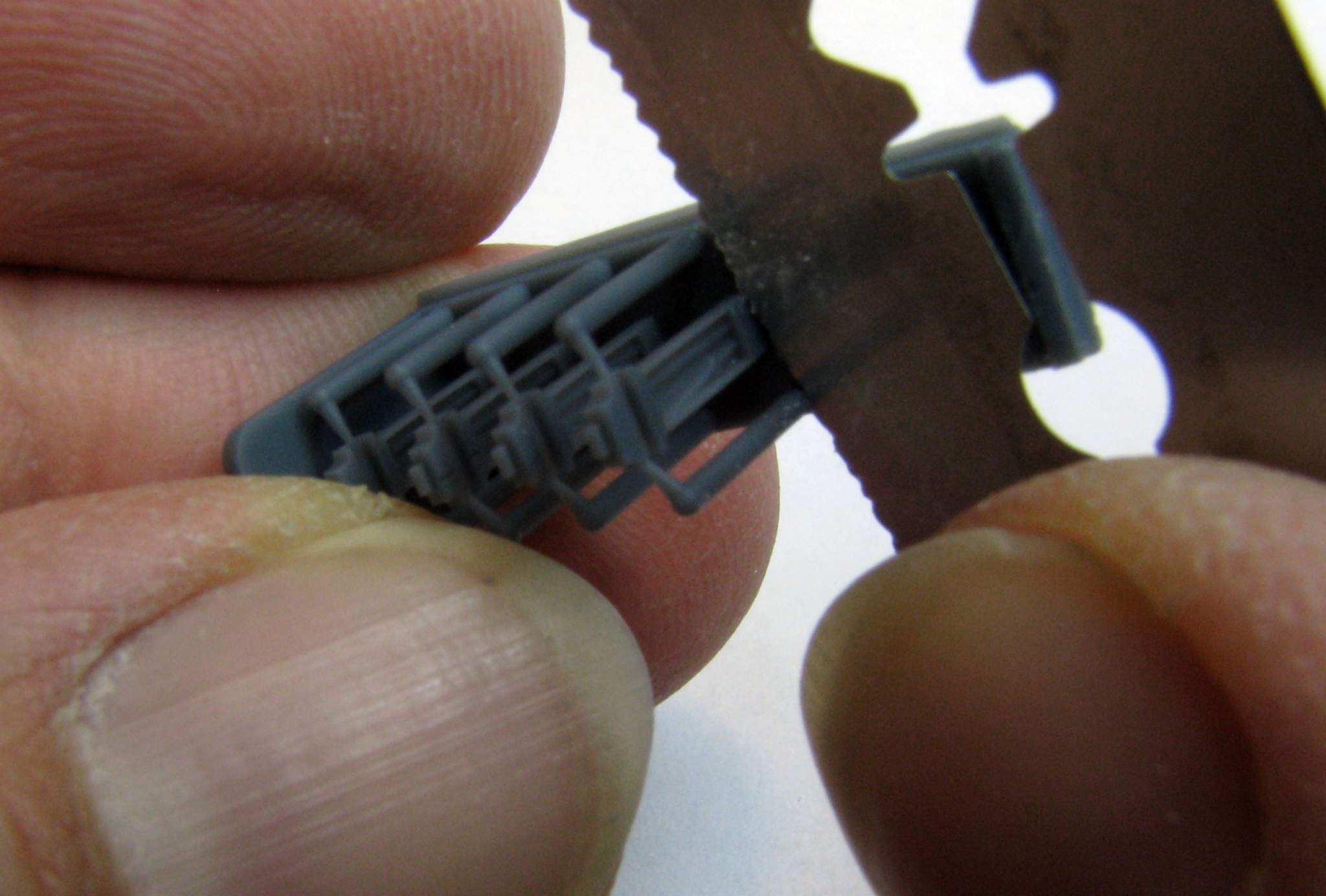

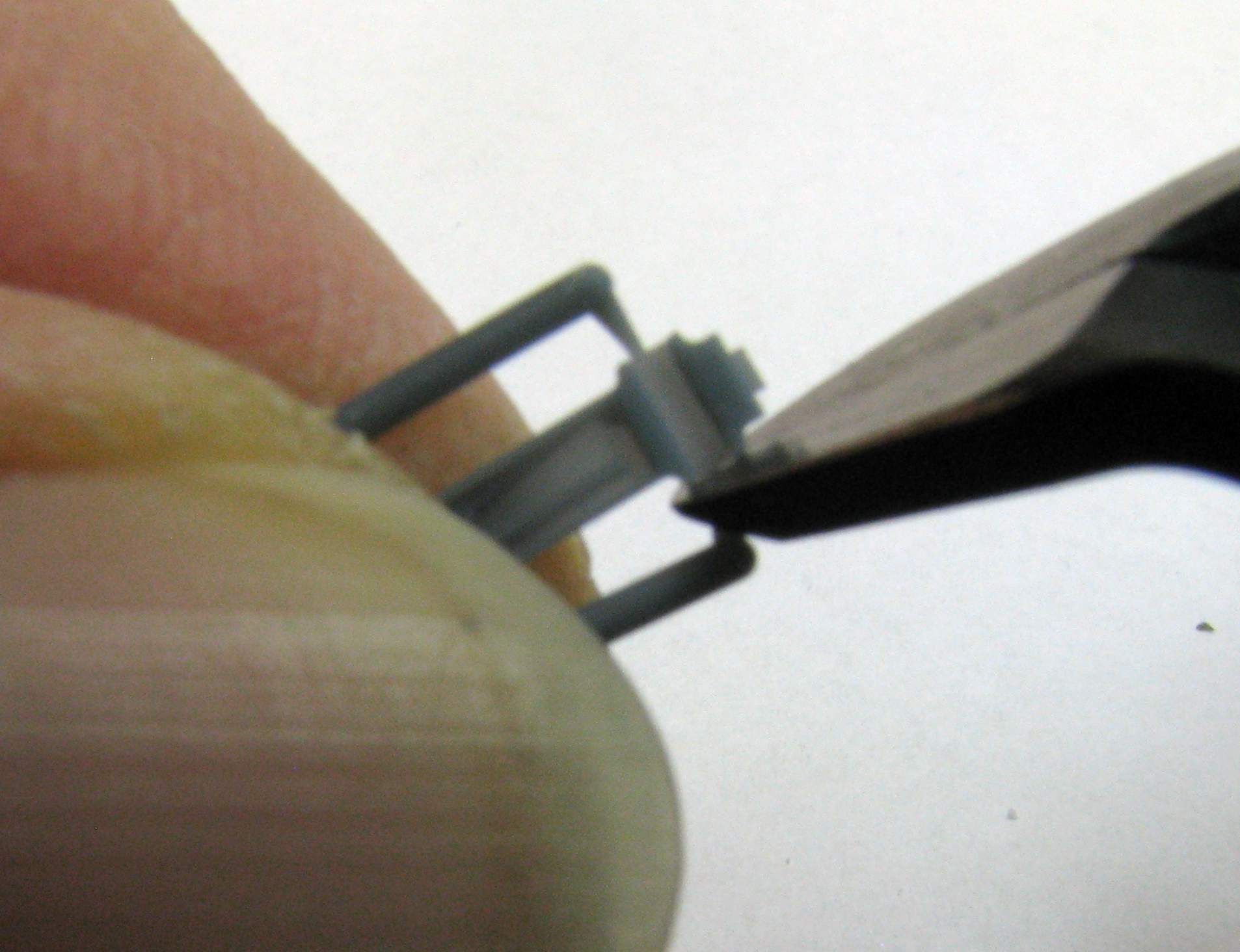

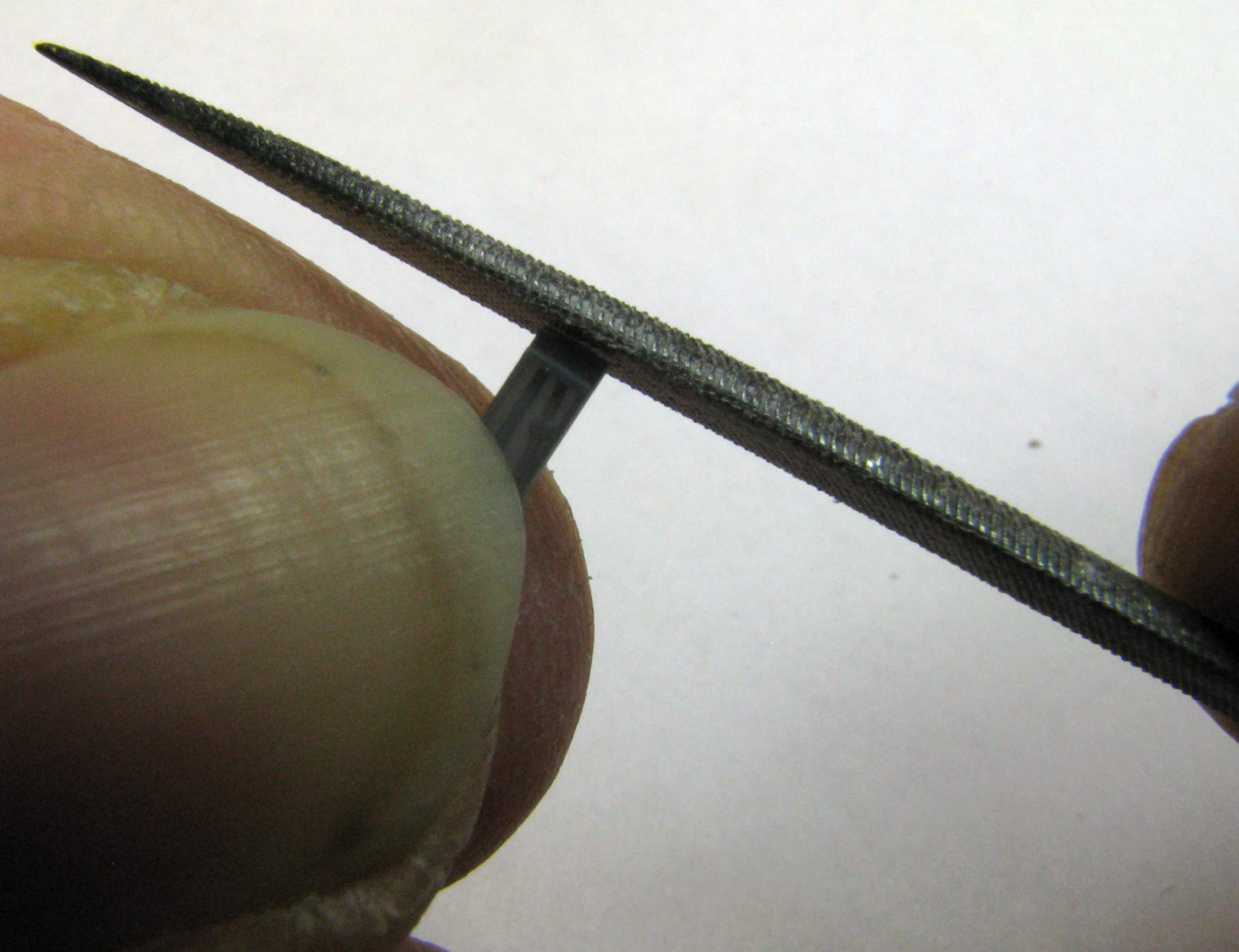

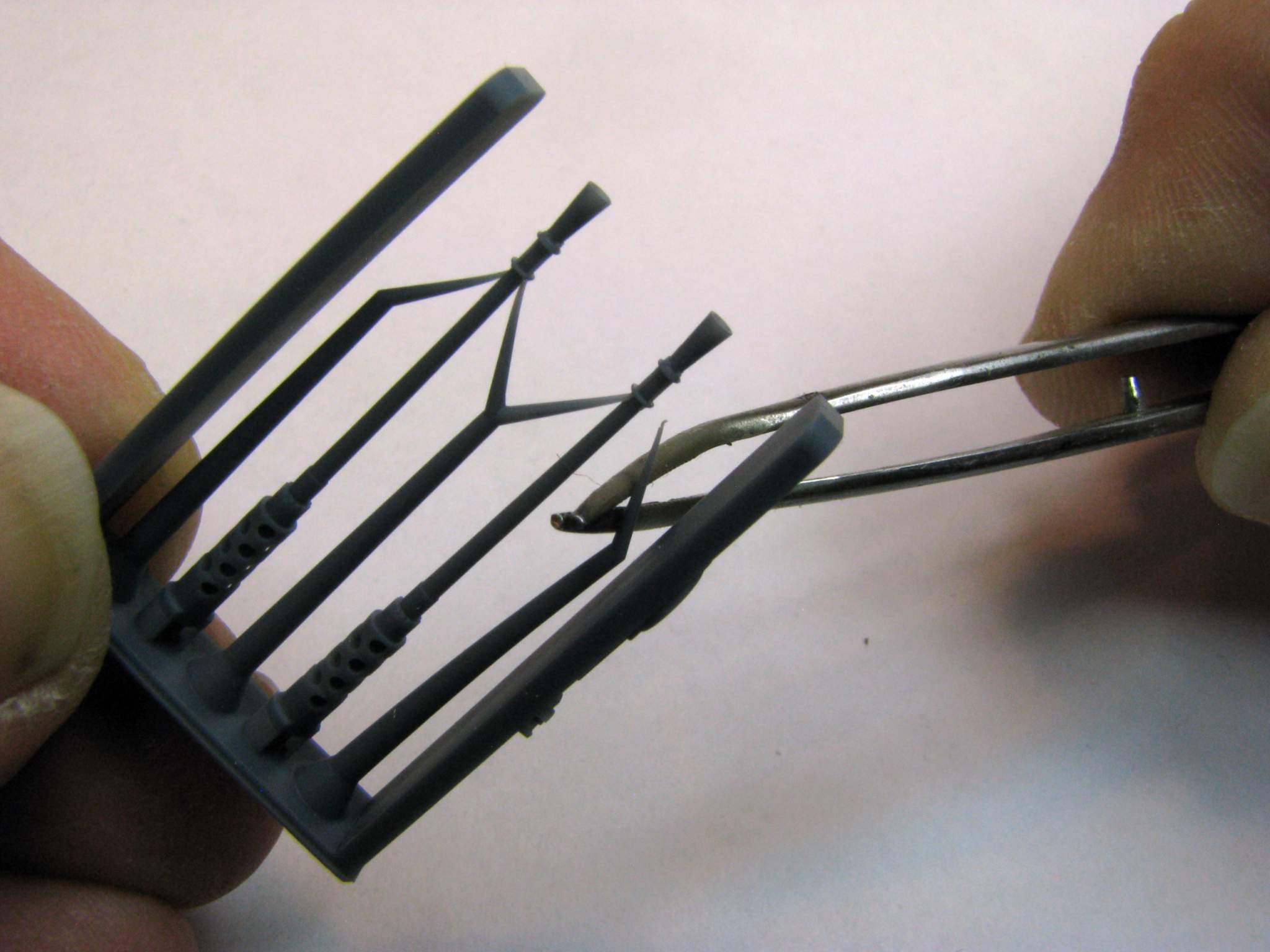

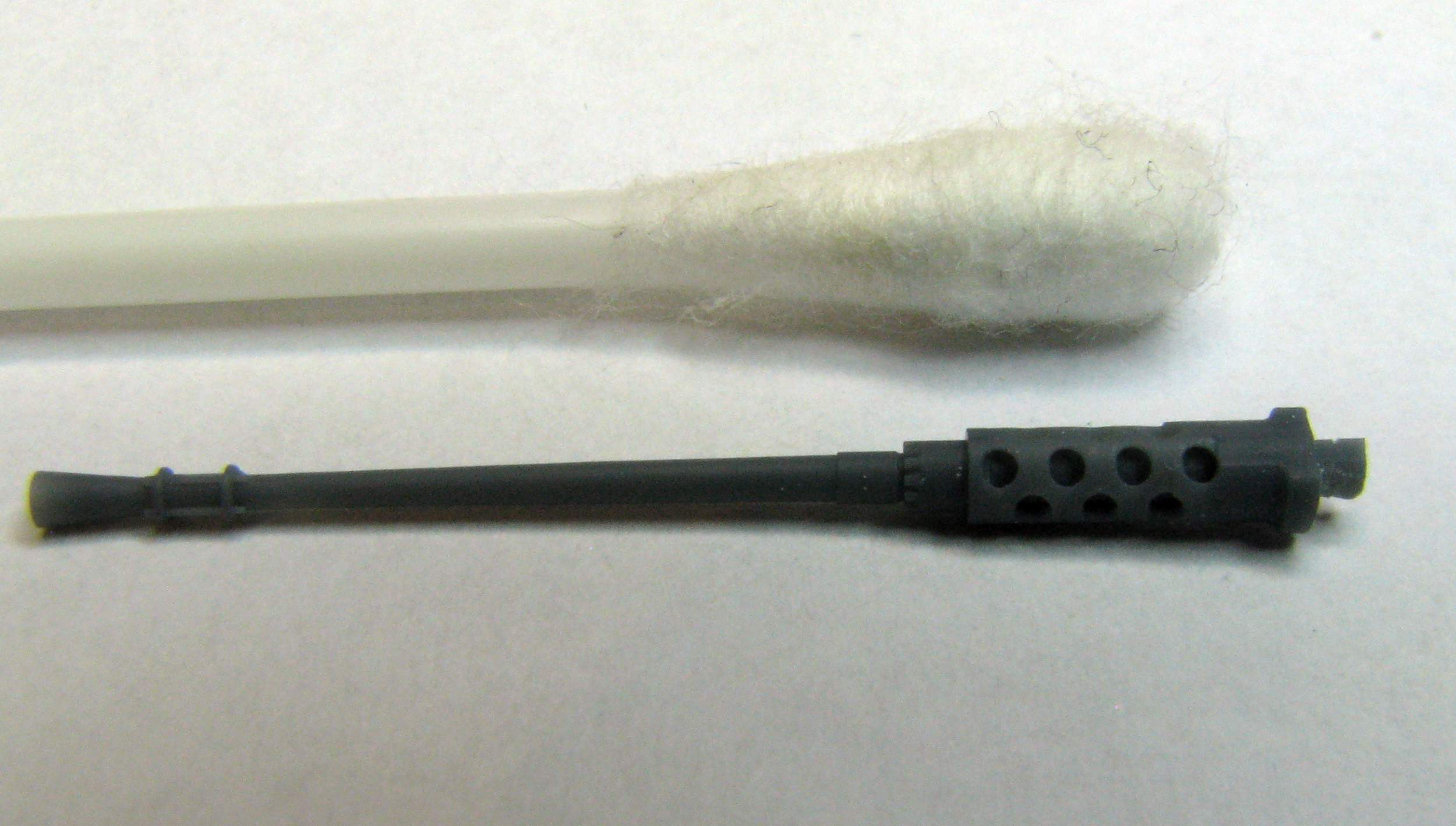

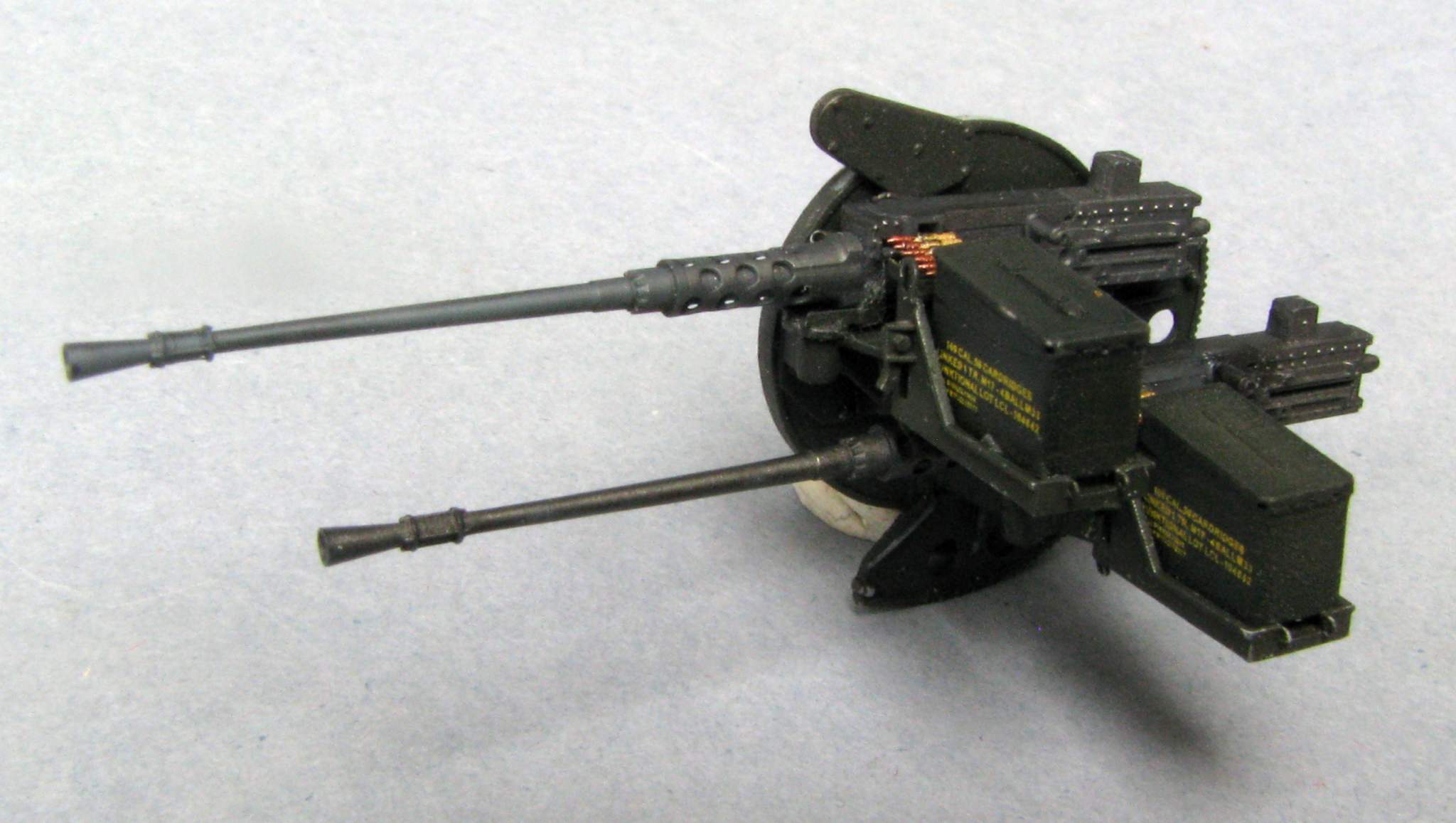

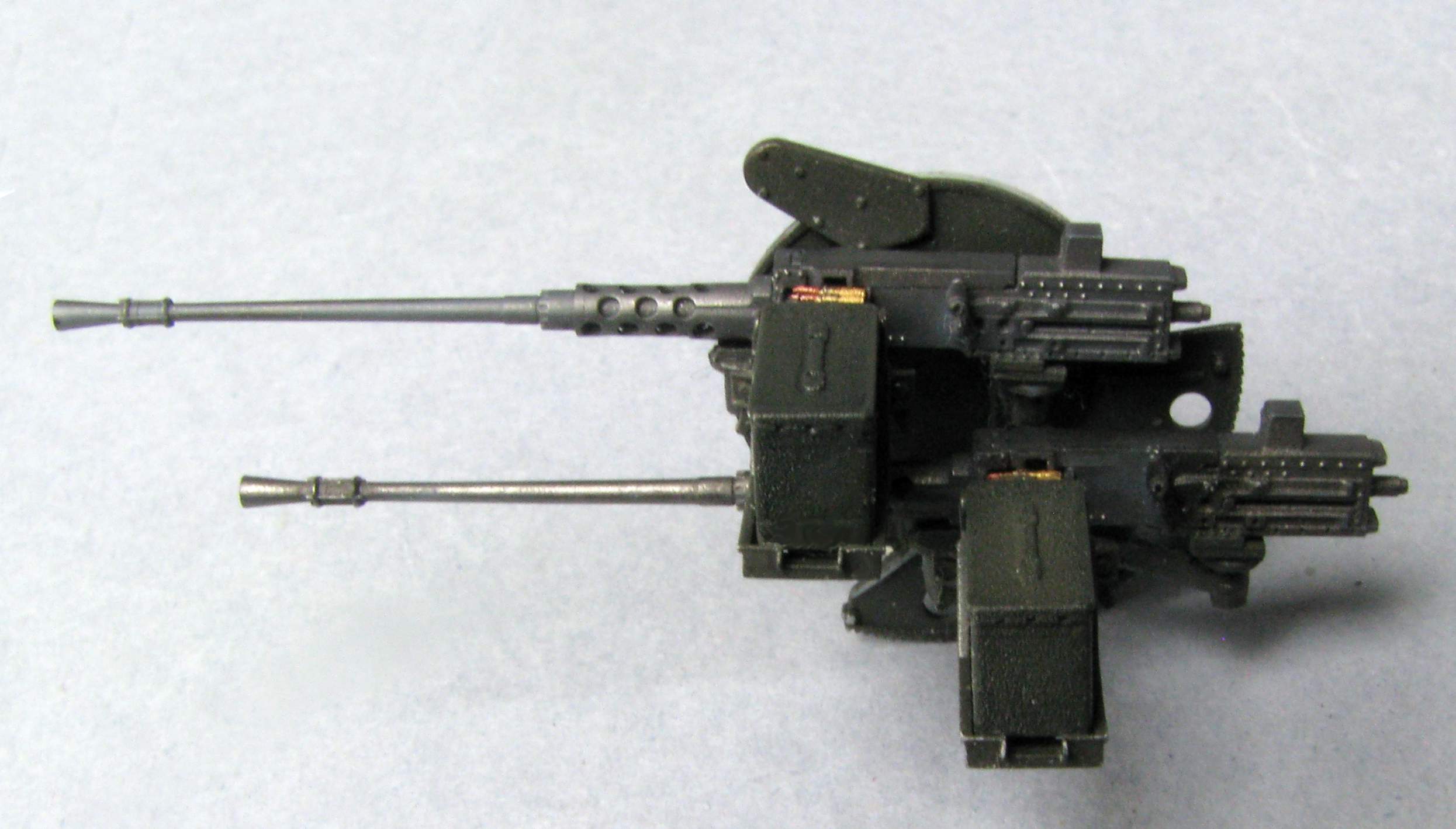

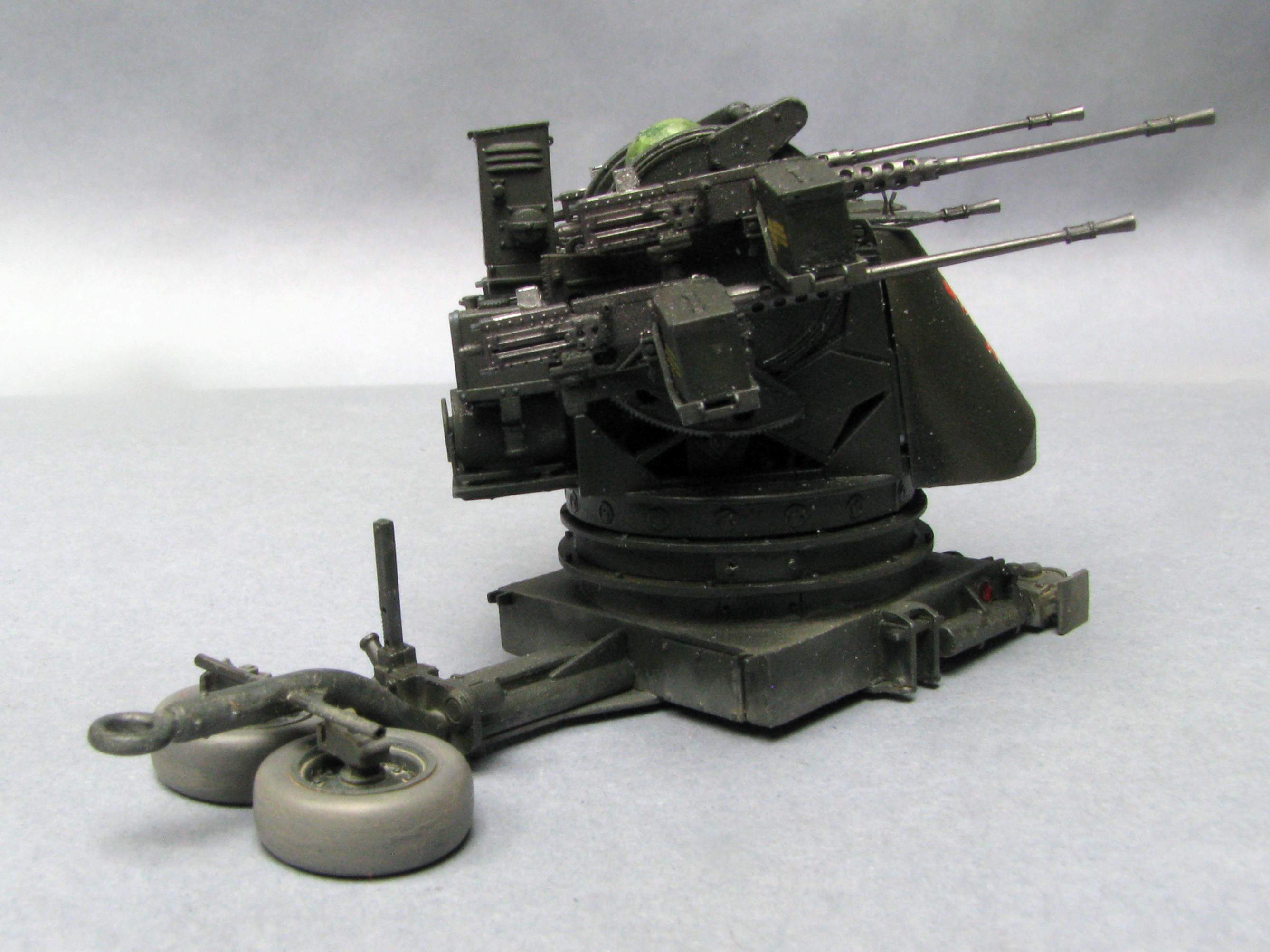

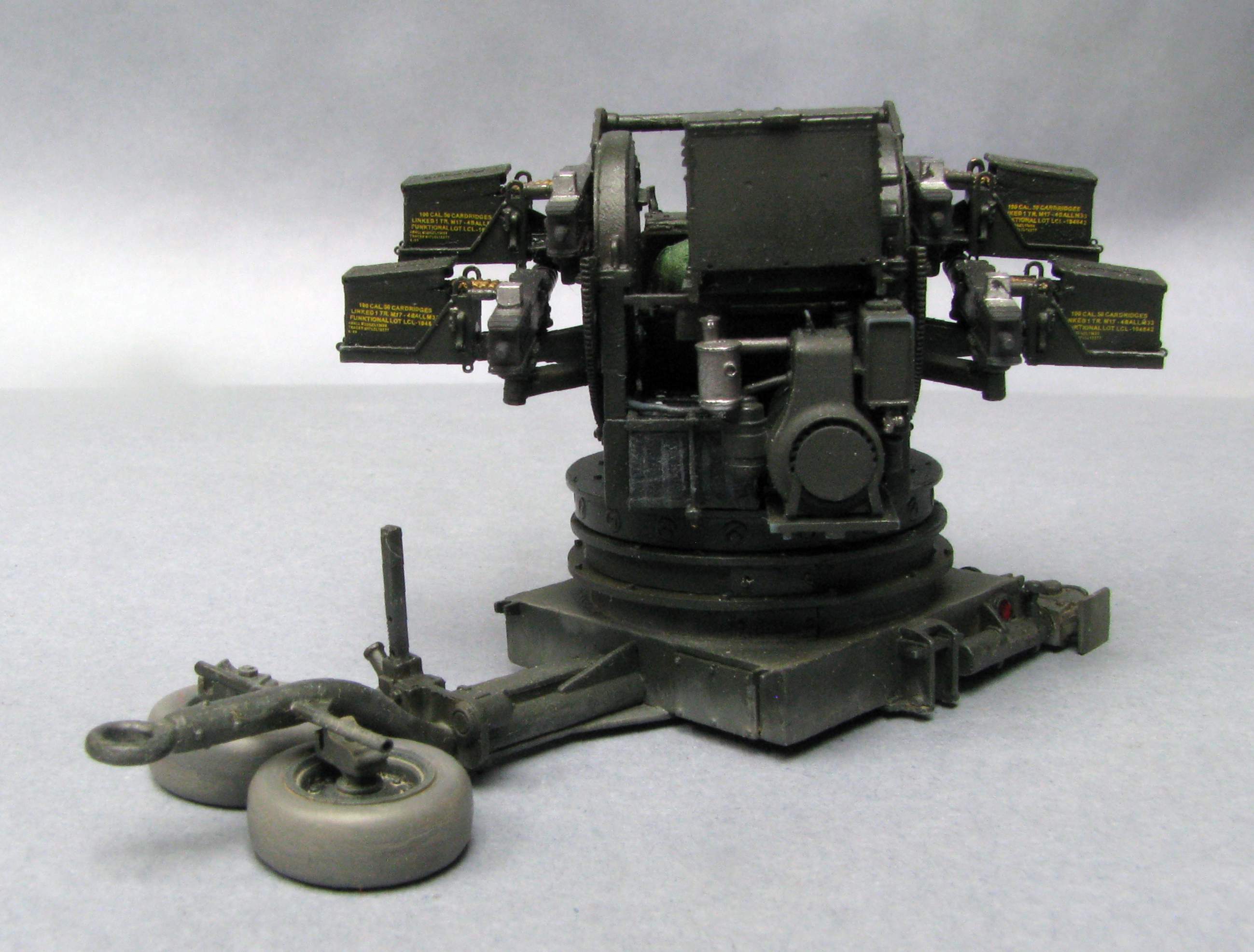

Now the Dynamo Models new kit consists of the now hard to get Dragon parts supplemented with some excellent 3D printed parts. Here are some photos:

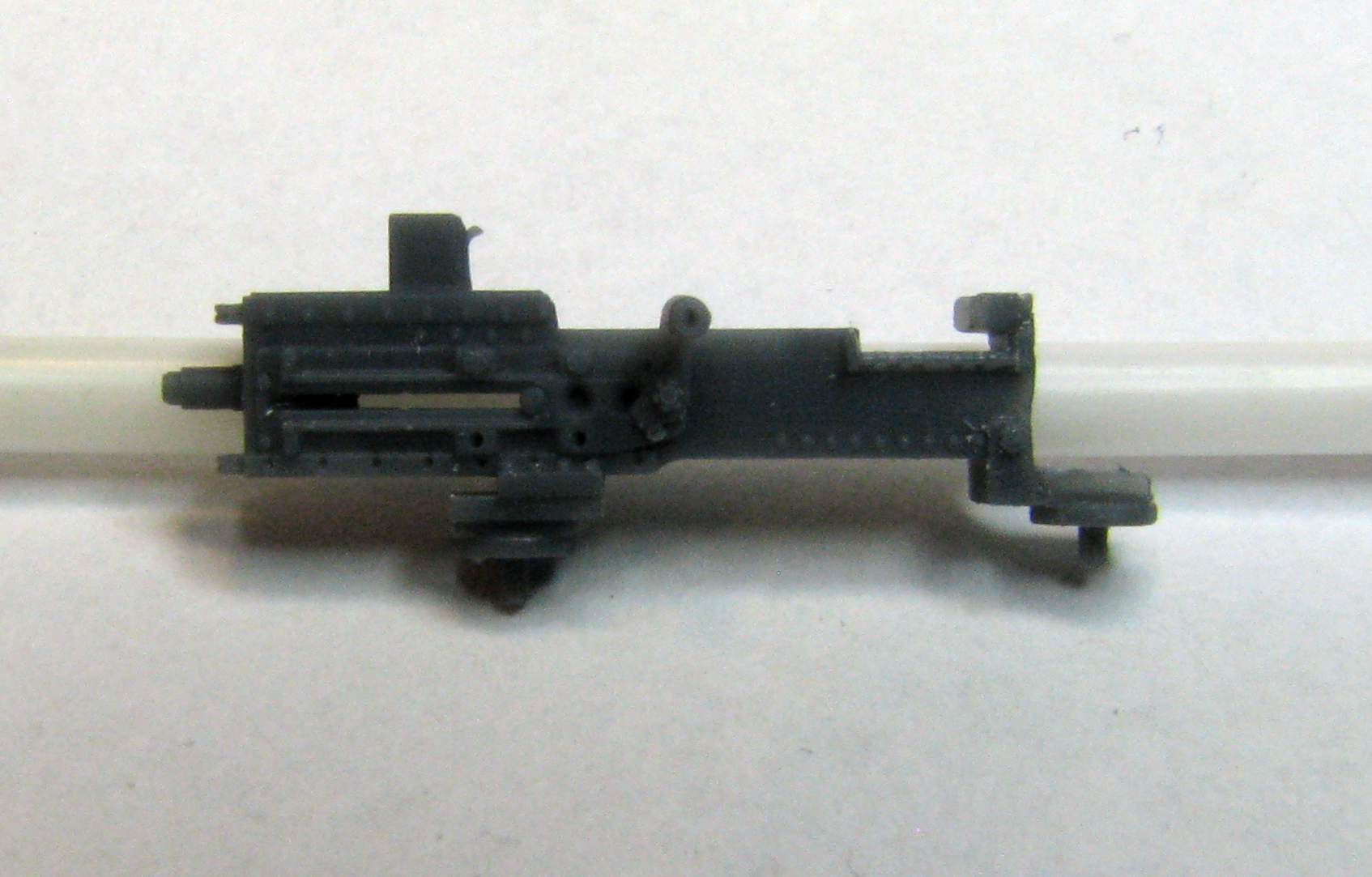

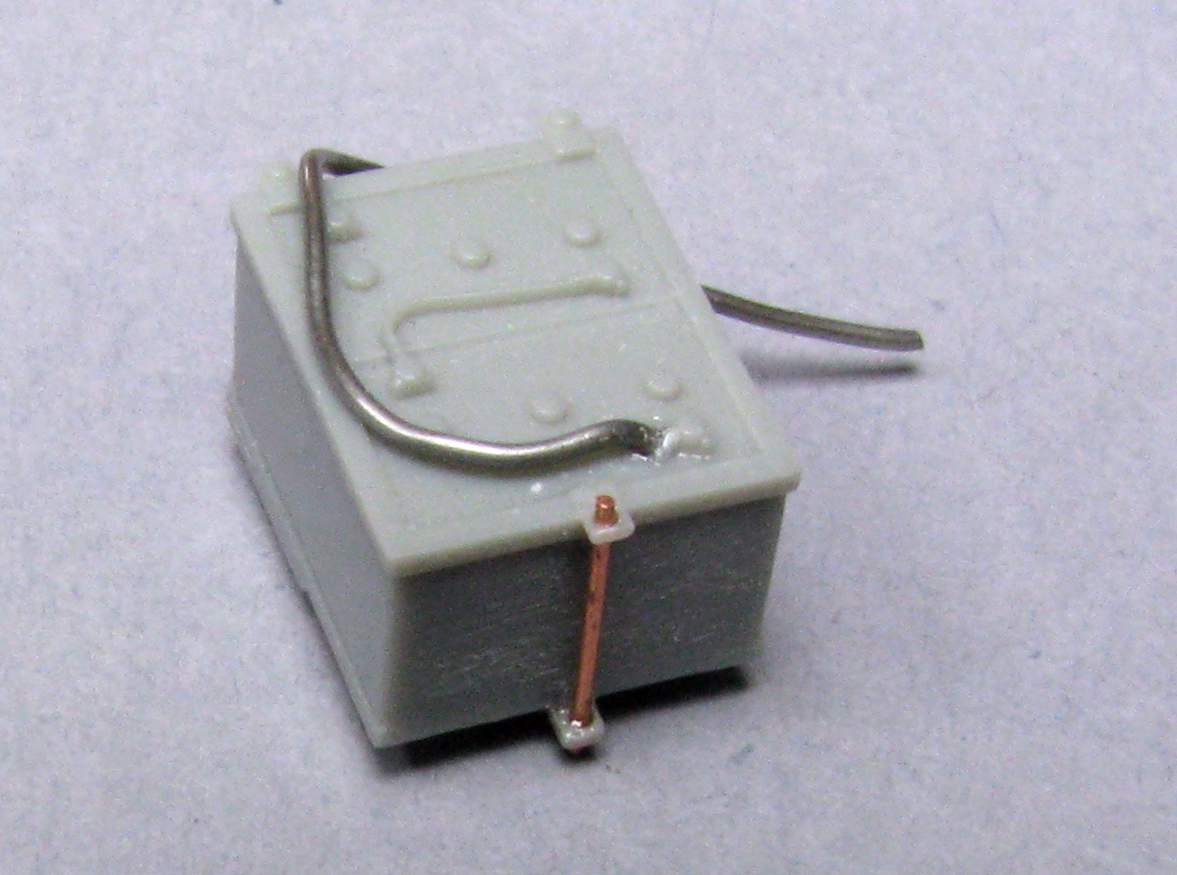

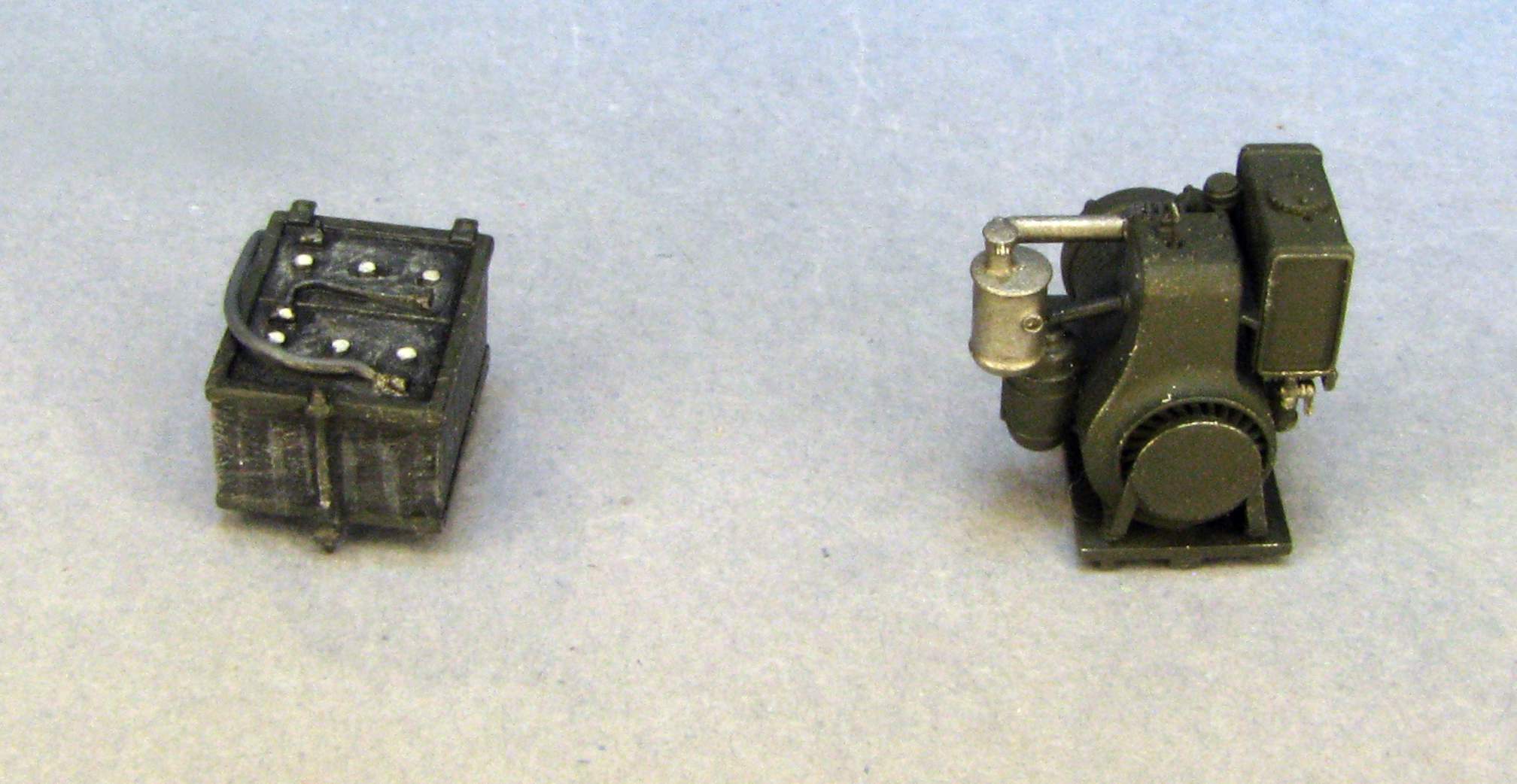

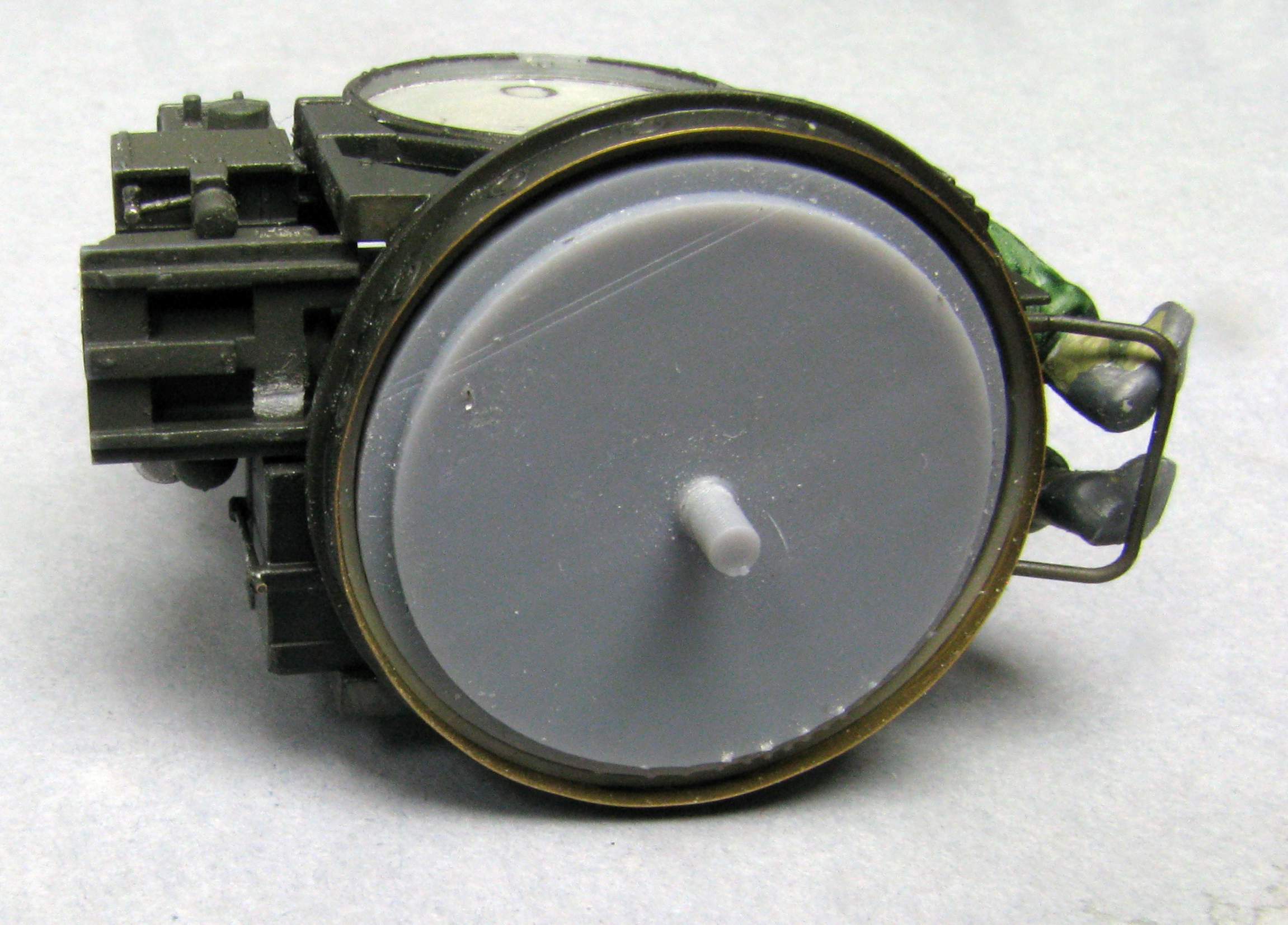

New power charger correct for Vietnam:

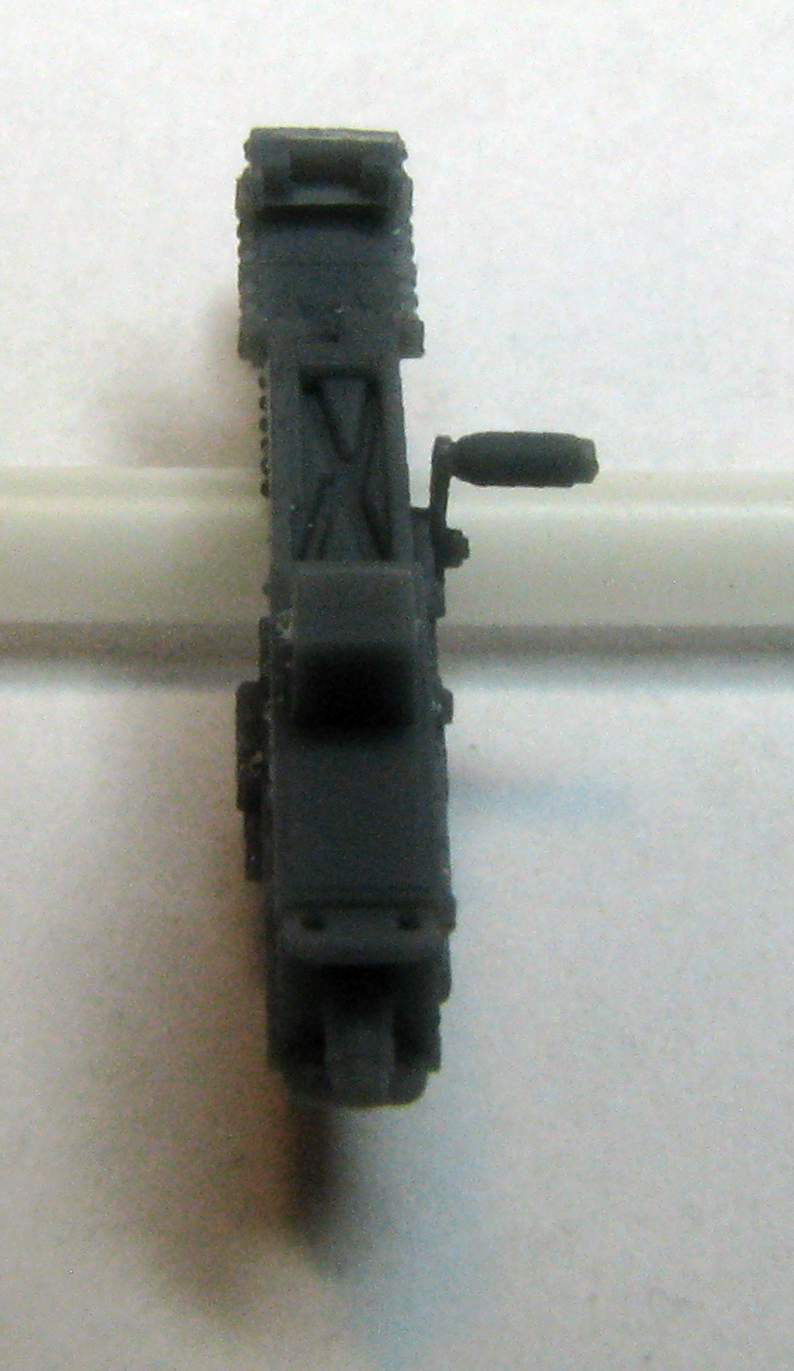

Control box:

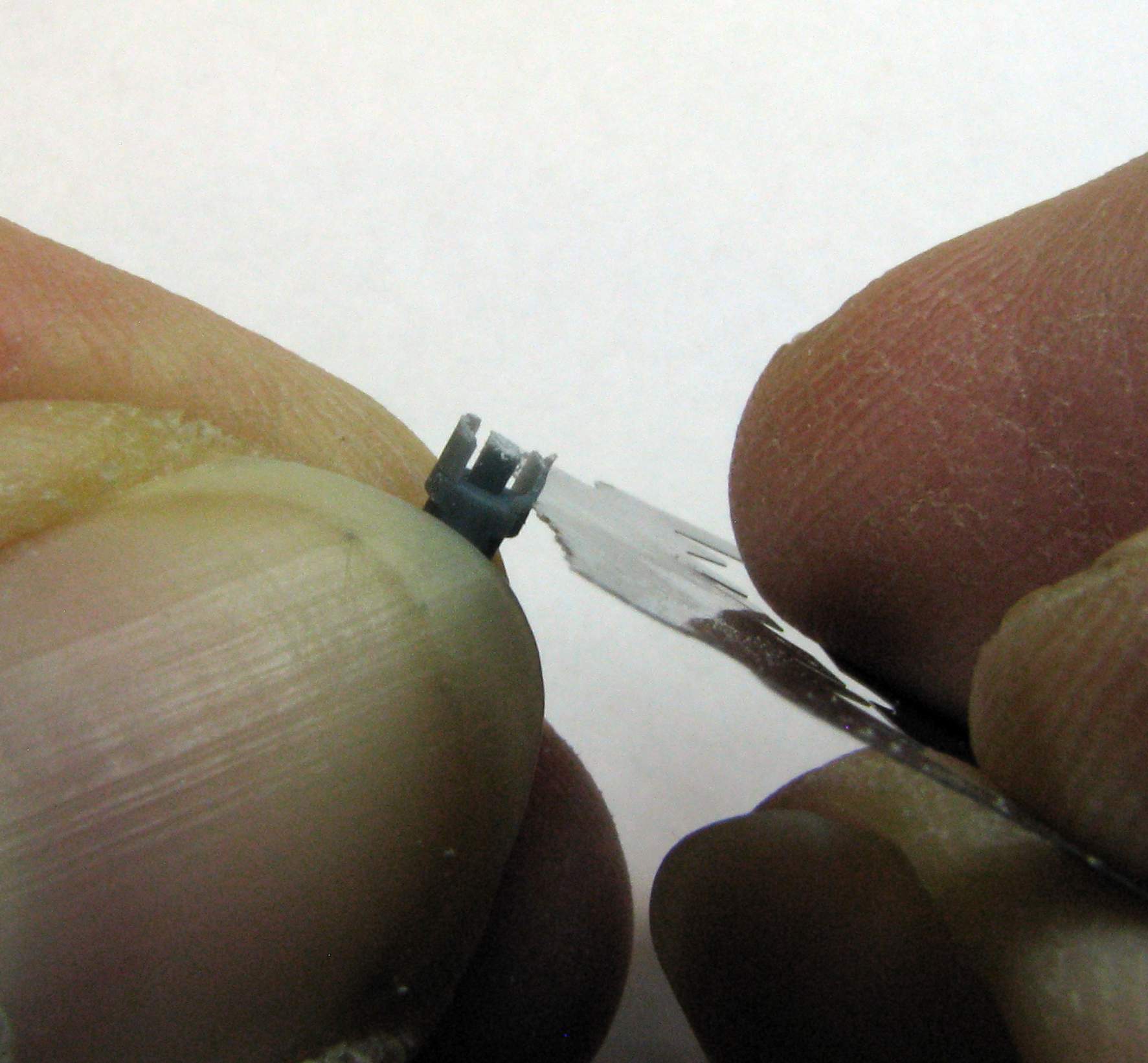

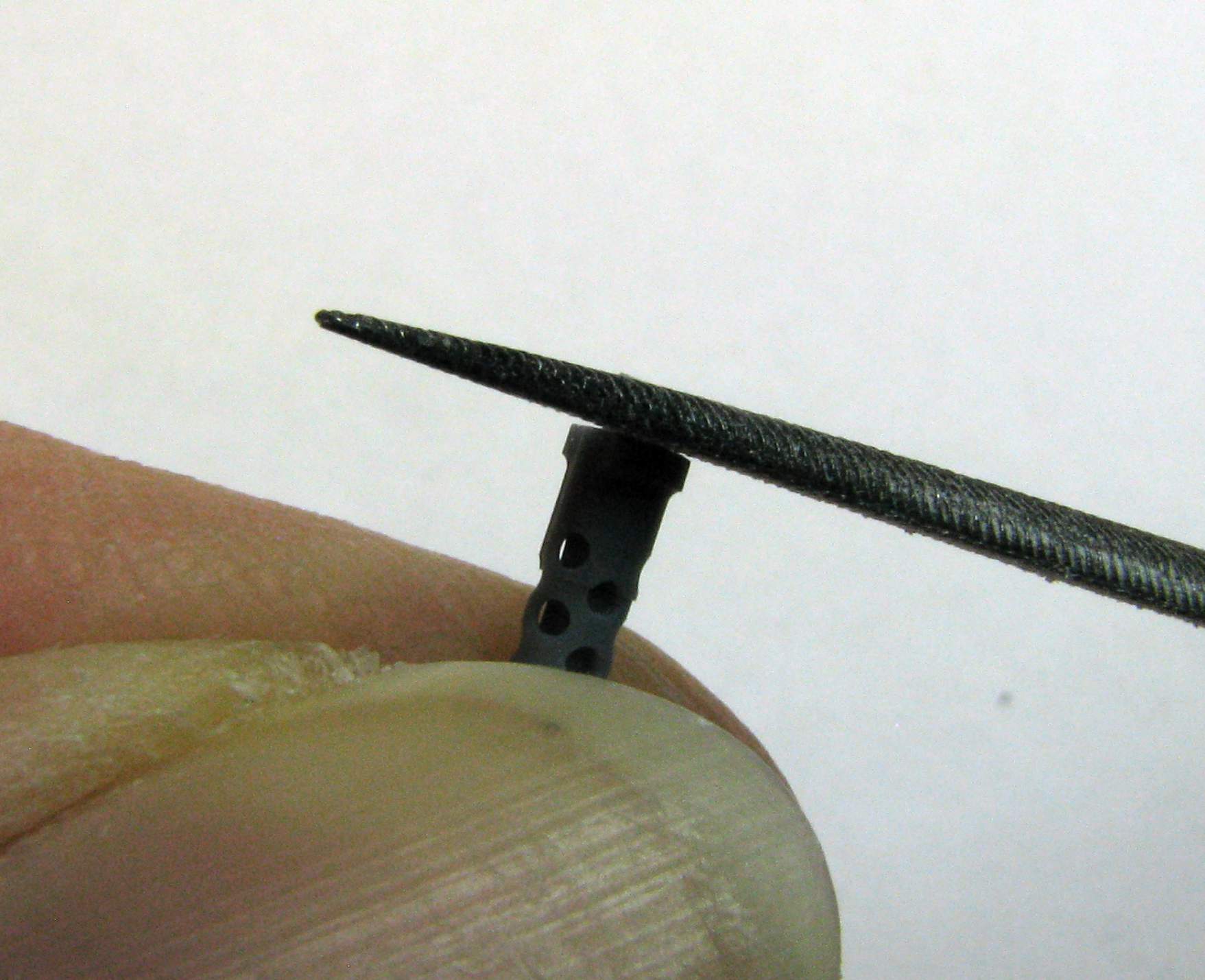

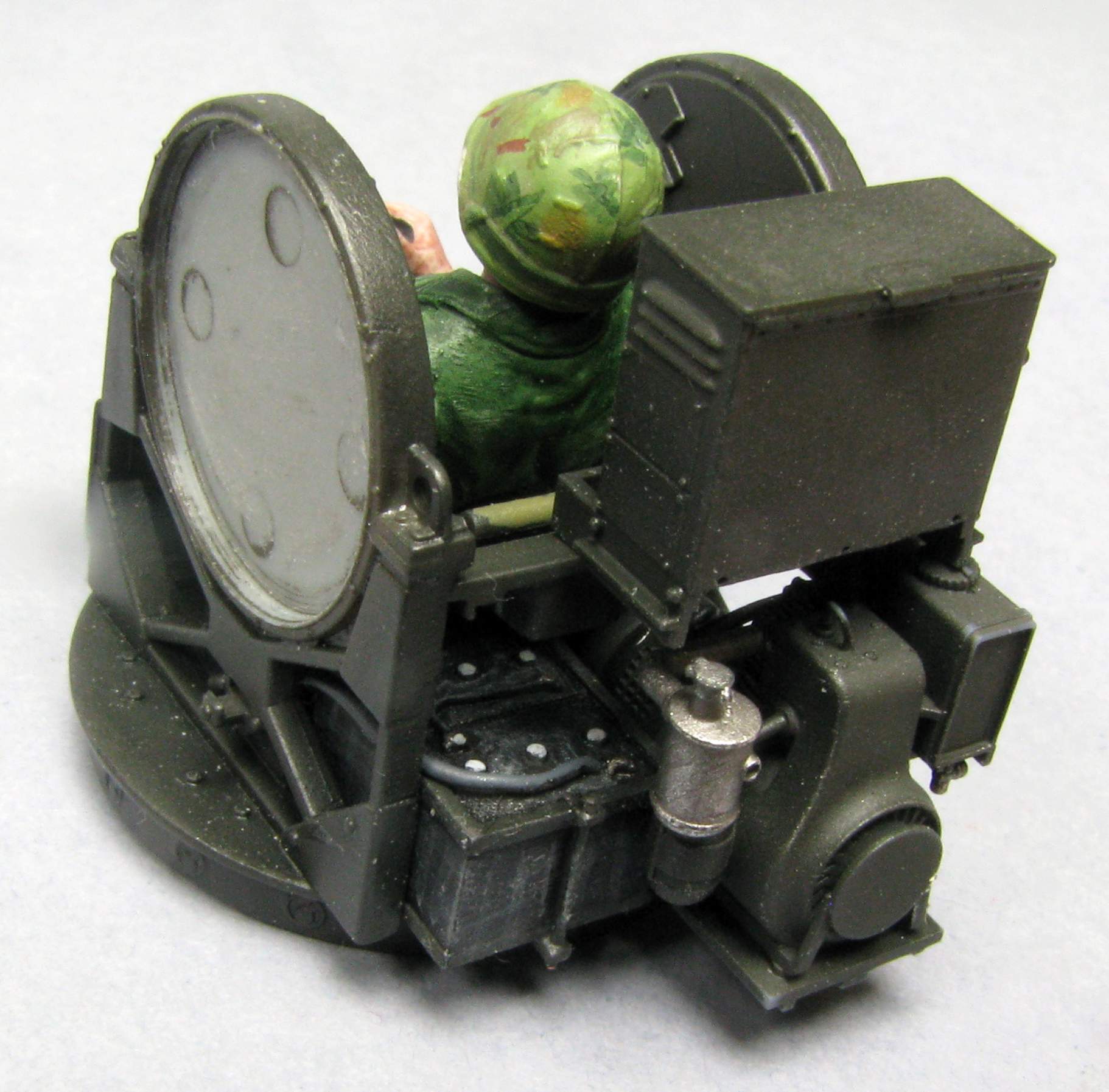

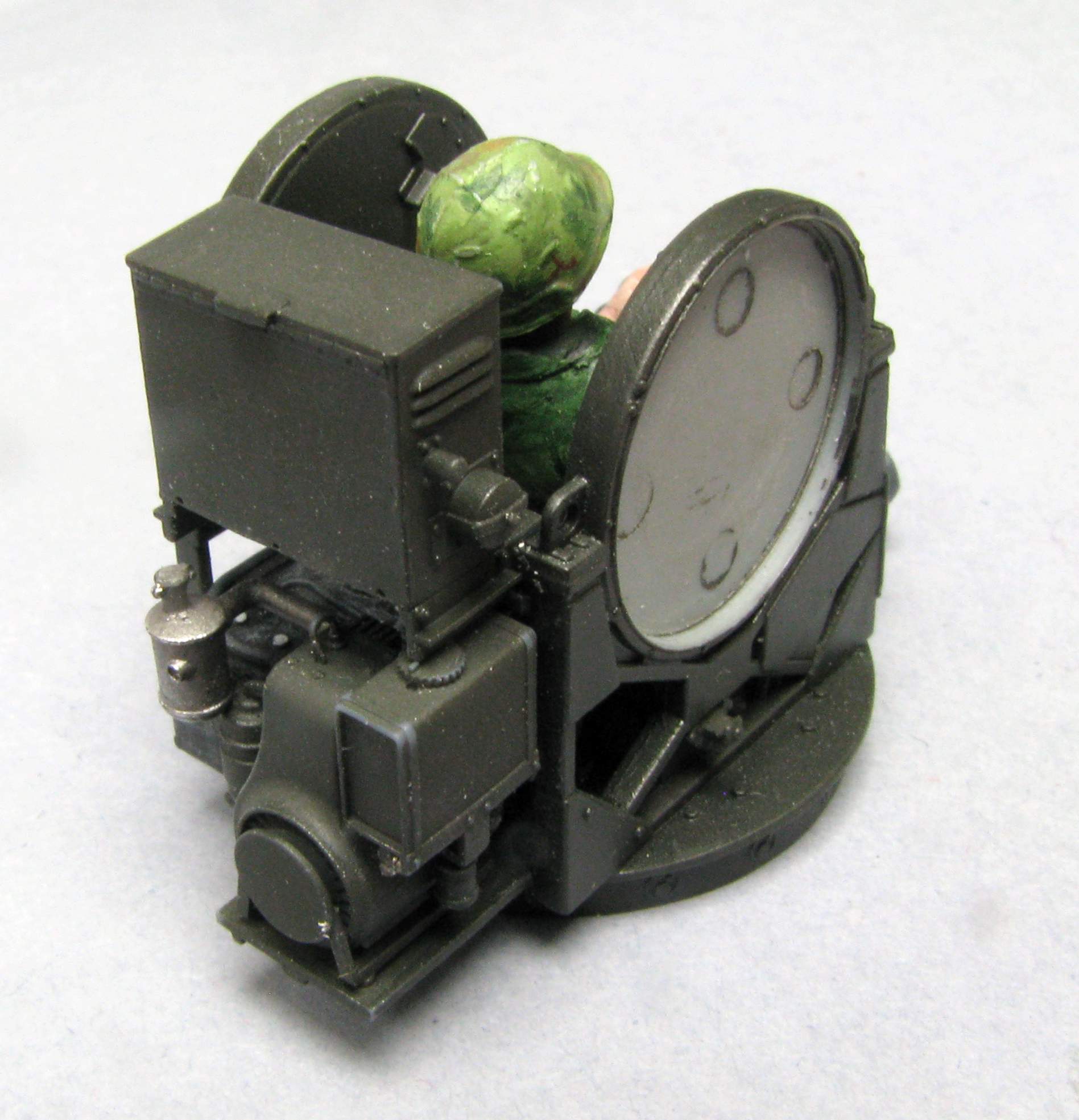

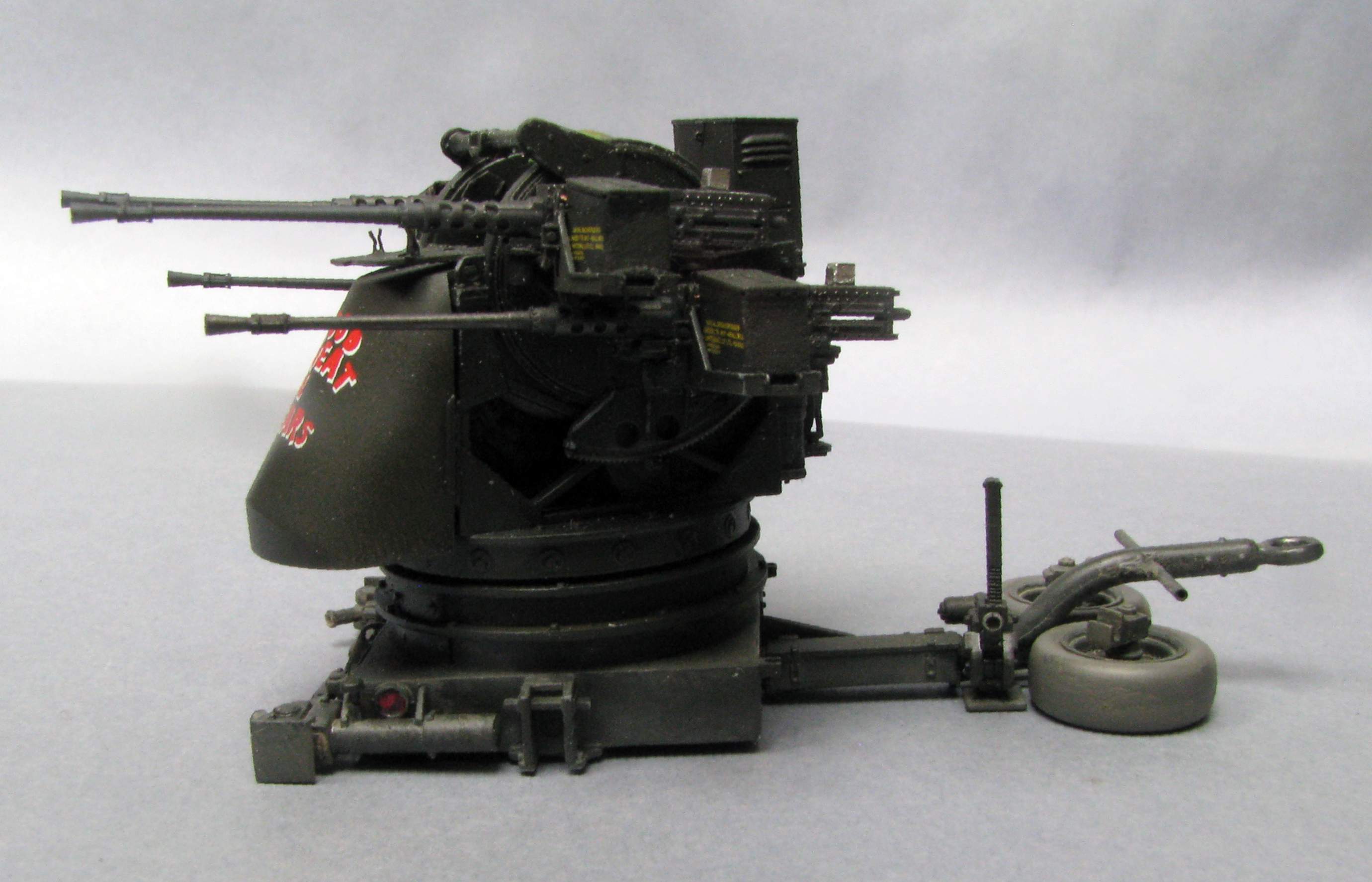

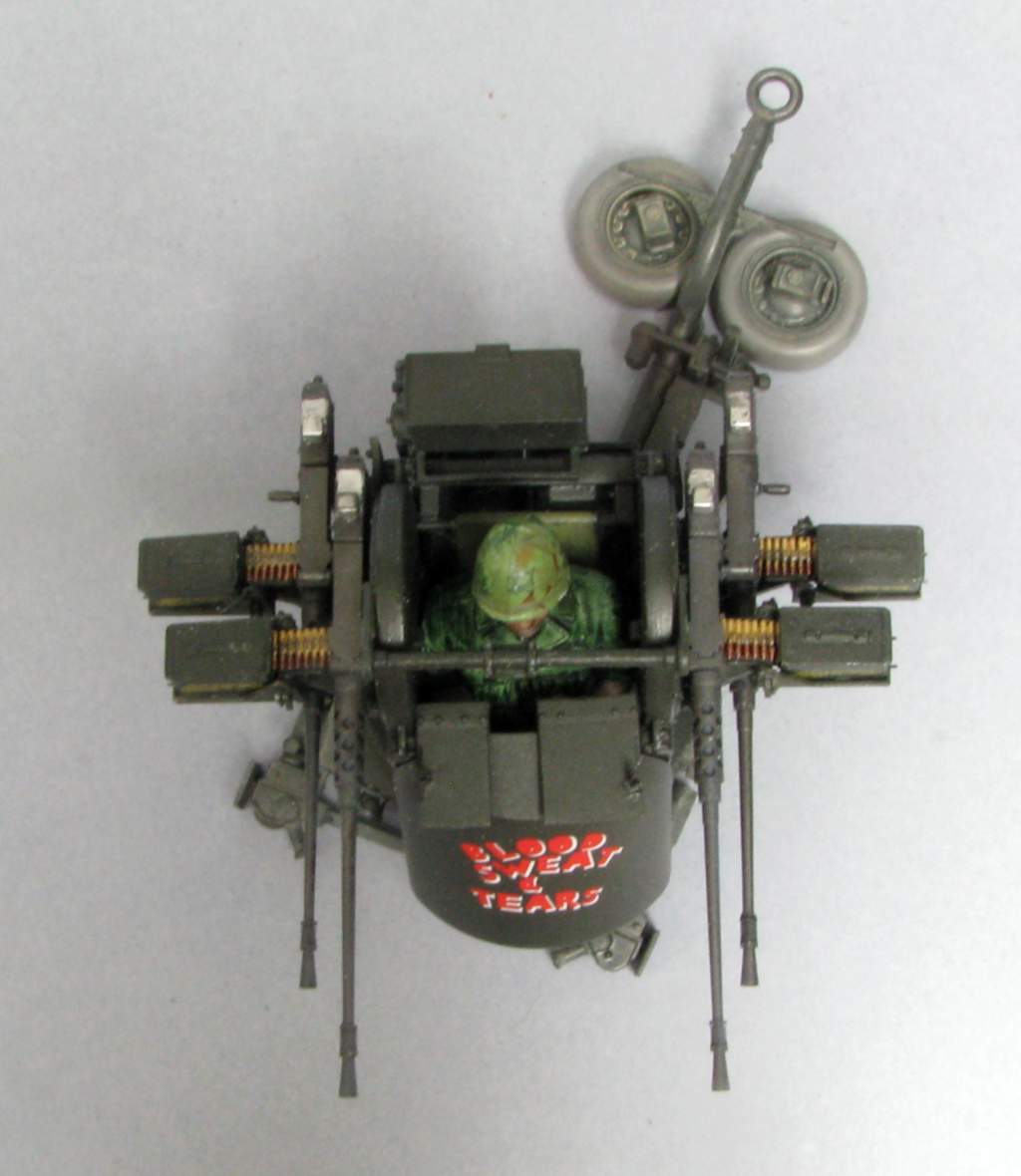

First thing I wanted to take care of is the gunner. The Dragon parts give you a nice figure of a gunner in a WWII uniform and the Dynamo instructions tell you only to use the gunner for the WWII version. I decided to convert my gunner to fit the Vietnam era. I replaced his legs with parts from a Dragon Vietnam figure series kit. Reshaped the arms to show the sleeves rolled up and substituted a covered helmet for the kit supplied one. I made the pockets out of Miliput. It took some serious fitting to squeeze the gunner in. Here he is dry fitted:

Now that I think about it I could probably save a lot of work by leaving the gunner’s legs alone as there would be very little to be seen from under the front armor assembly. But the blouse/jacket is definitely worth doing, as is the helmet.

I have also assembled the basic frame of the quad and painted the insides black with Gunze paint. This paint is dissolved by the thin plastic glue that I use, so no paint scraping necessary, and the black paint helps with painting the insides a lot, I get natural shading and don’t have to worry about unpainted spots.

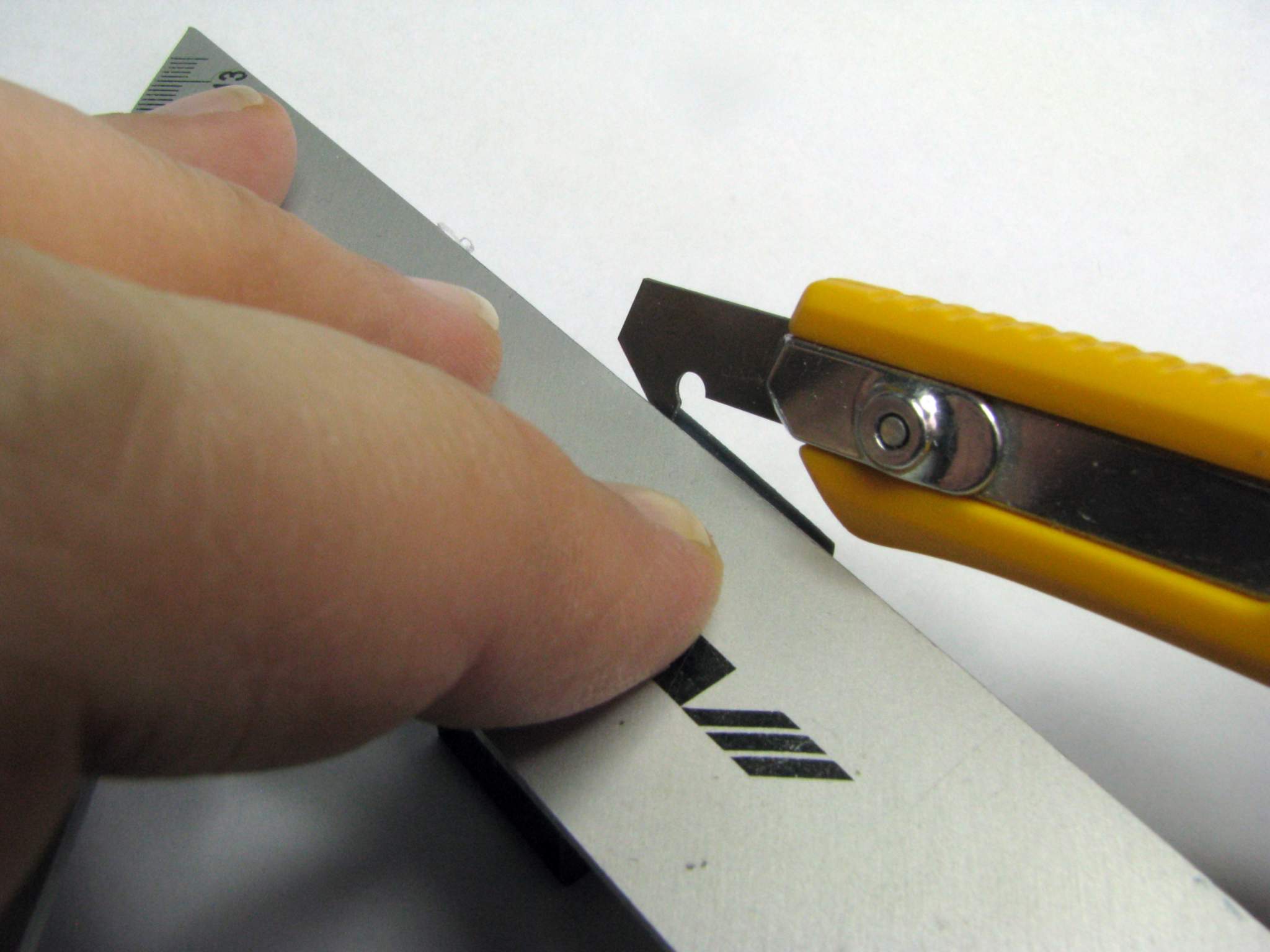

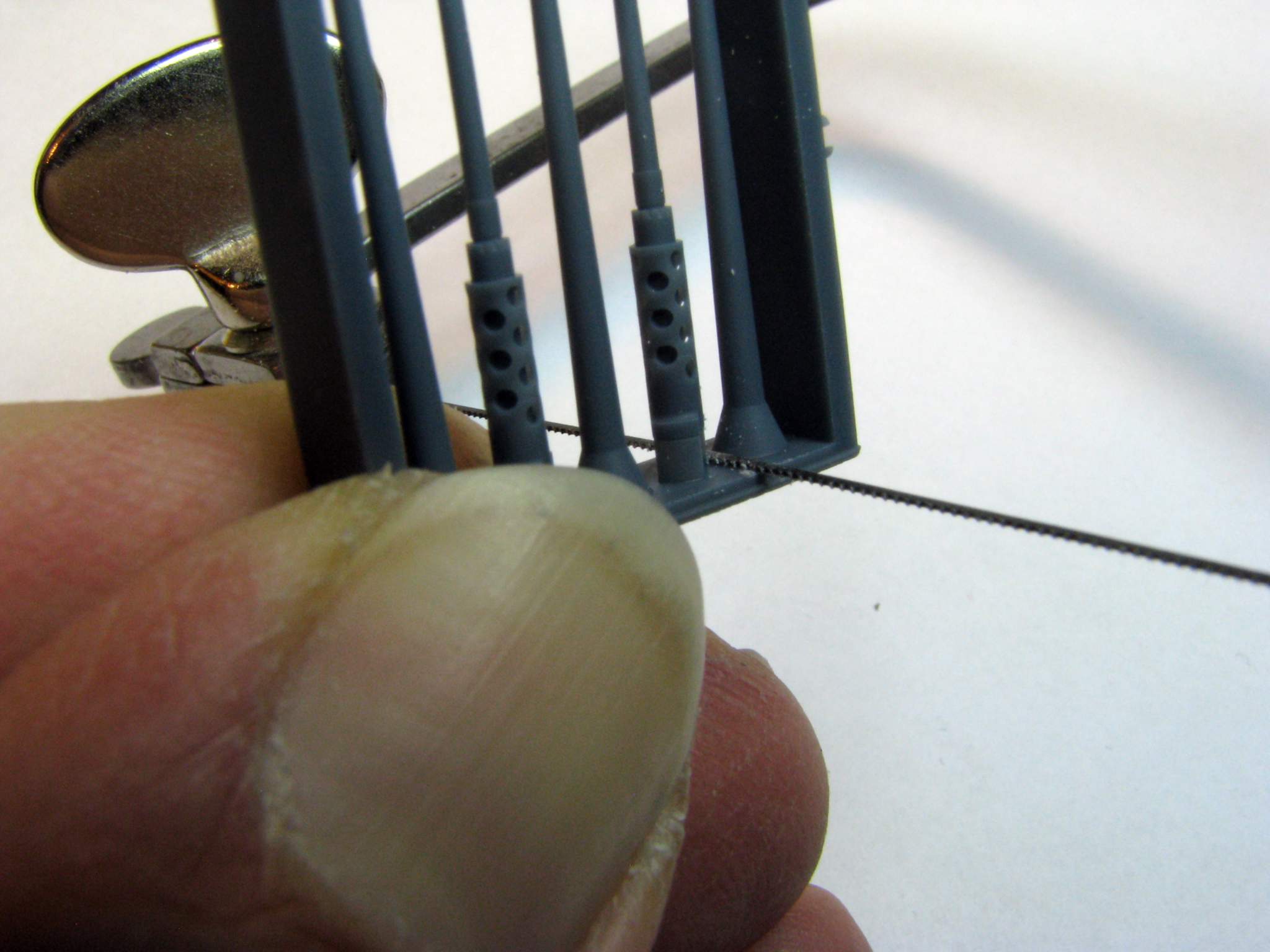

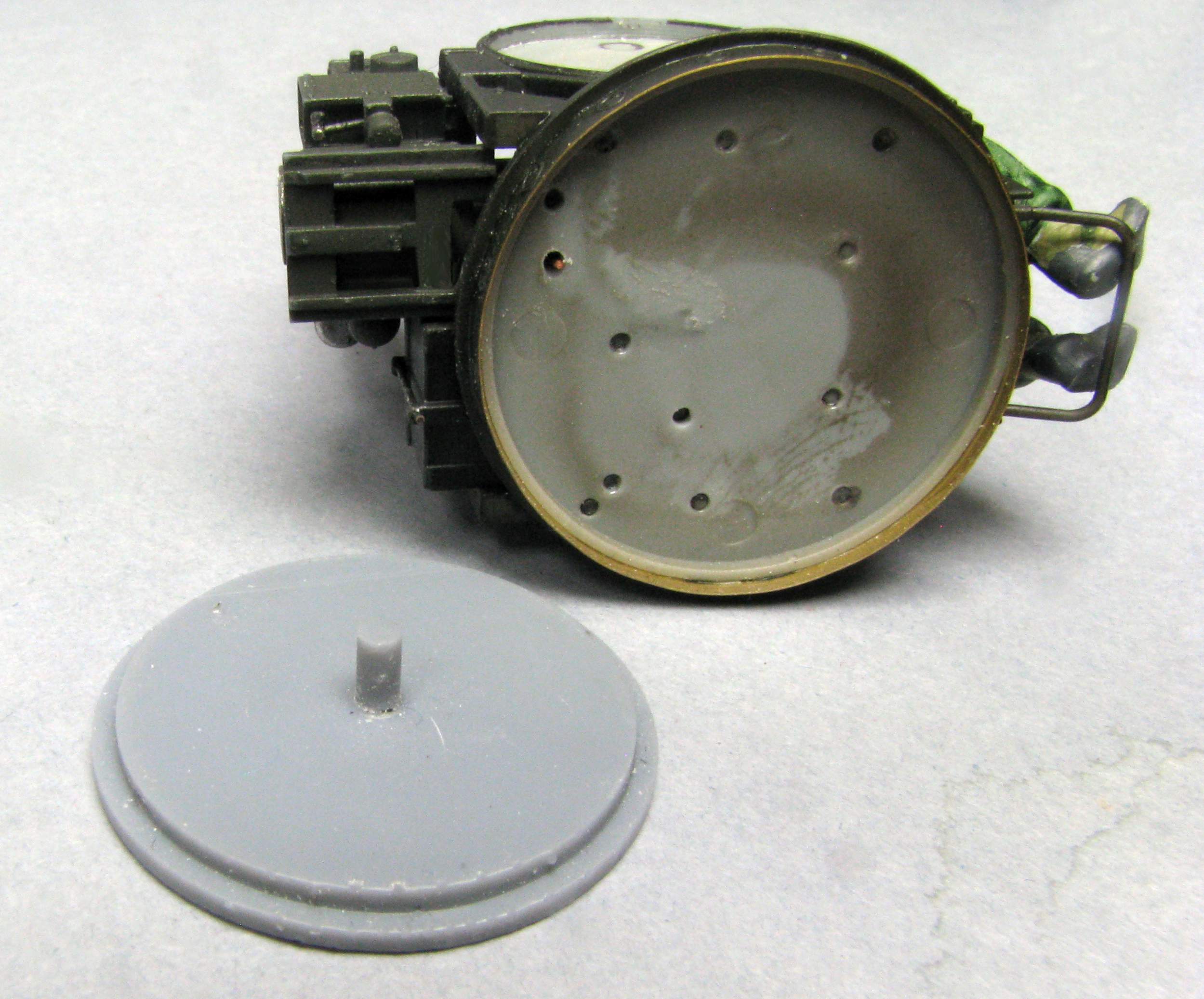

At this point I have also installed the only PE part from the kit - the stripe around the base bearing. It needs careful shaping and fitting, but if you take your time it fits OK. One funny thing is that the stripe is about 2 mm wide and the plastic ring it fits onto is only 1 mm wide so the ring stands out a little, don’t be surprised about that.

I painted the gunner using acrylic paints by Games Workshop and here’s how he fits the chassis:

I don’t want to make this post any longer as it is already quite long… So please stay tuned for updates!

Thanks for reading and have a nice day

Paweł