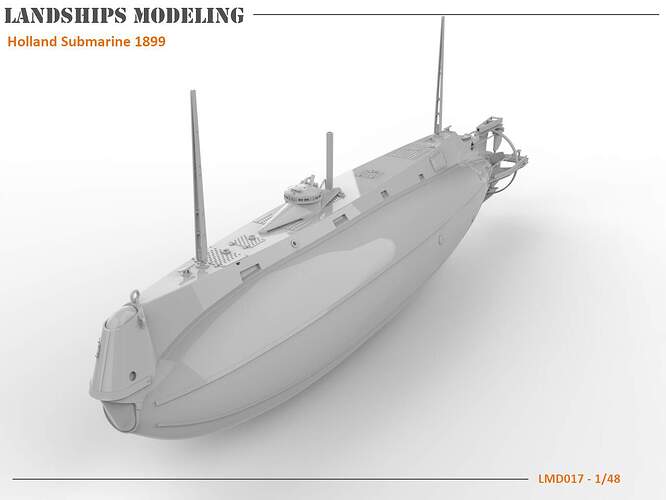

I’ve been wanting to build a Holland submarine for a while now since it relates to my current career. But with nothing readily available I decided to design one myself and 3d print it. 1/48 is a nice scale for smaller boats which will bring this thing to a little over 13.5" long. Making the 3d model was a learning curve, with a few false starts. It’s a safe bet it took me over 80hrs just to get to this point

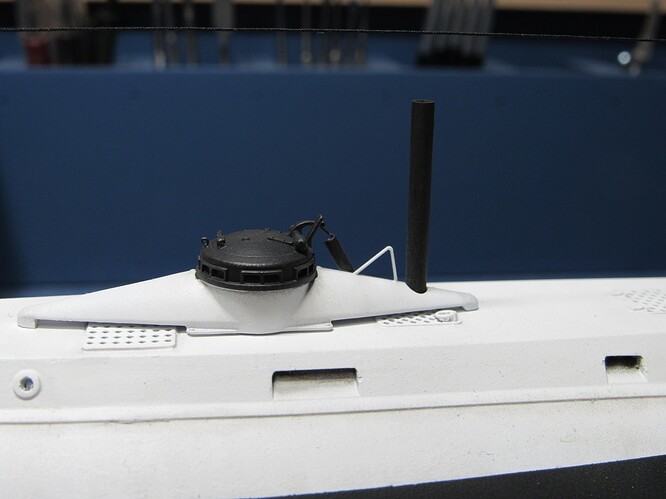

This is the Holland as it was at some point in 1899, before Navy trials. It went through some heavy modifications during its trial years, the most noticeable change between this and when it was commissioned was the front superstructure being narrowed.

Naturally, I managed to brick my 3d printer a few weeks before I was ready to start printing this. Turned out to be a blessing, as I picked up an Elegoo Mars 2 for only $100 more than a replacement screen for the old printer. I invested in a heating unit too, and now I have prints that are actually presentable.

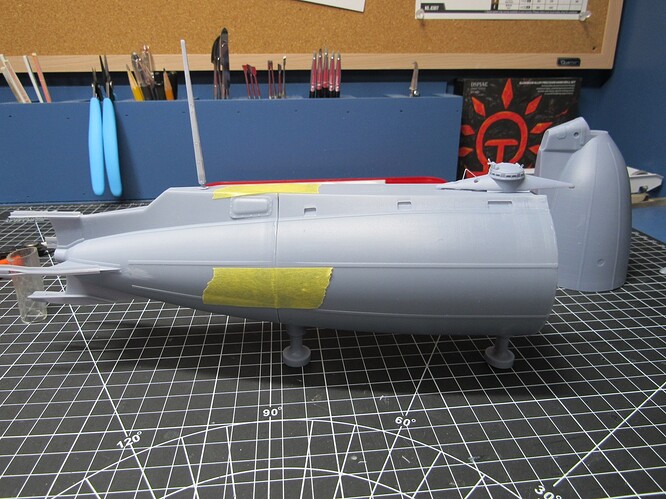

Time to start churning out parts,

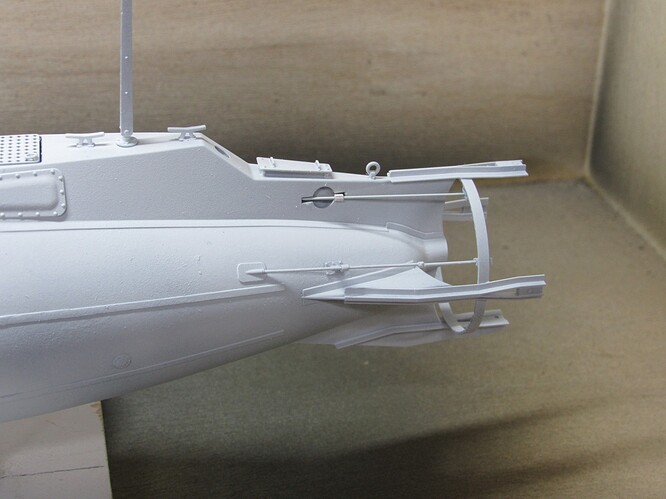

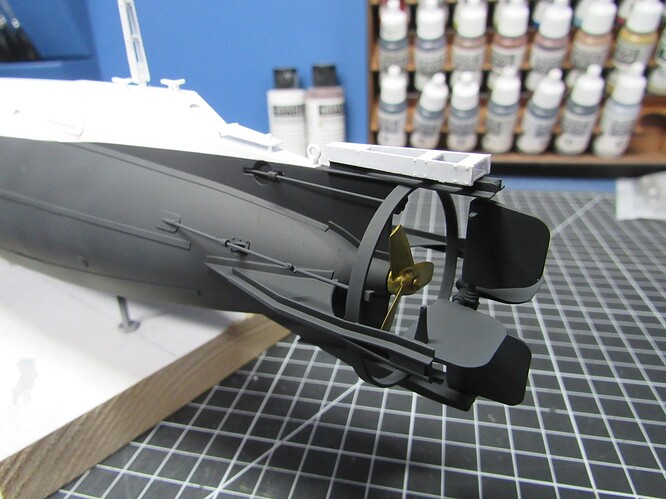

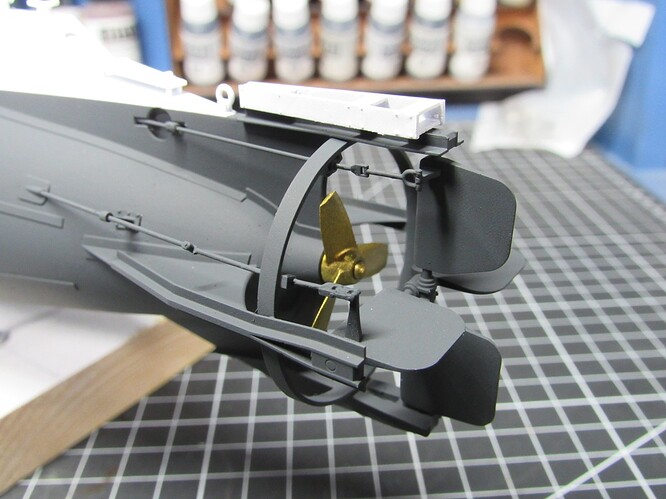

I divided the hull into 3 sections, forward, mid and aft. Each one takes about 18hrs to print. I had a couple failures due to parts of the raft peeling from the build plate, but upping exposure time on the first layers, and the layer count fixed it. The forward section will need to get reprinted because of this, you can kind of see how it doesn’t sit level.

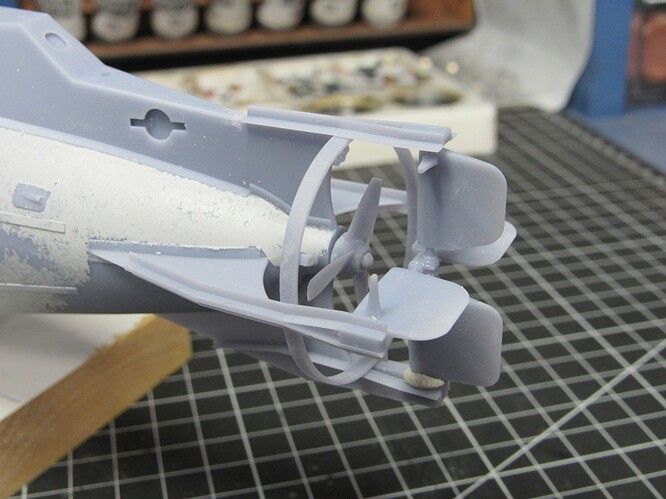

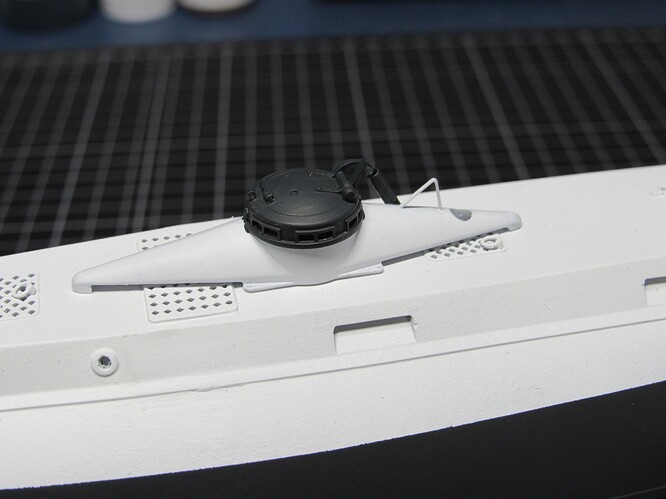

Got some detail parts out too, like the conning tower,

Due to the shape of the submarine, standard mounting pedestals won’t work, so I made my own that comes with the kit.

Pinned in place right now with a plastic tube, but it’s designed to easily take a 1/8" threaded rod, so you can bolt this guy down to a base.

I did catch an error that you can see in the last picture. The bands that run along the hull taper to nothing where the aft and mid sections join. It was a modeling error that has since been corrected, but I don’t want to reprint, so I’m gonna try and fix with some 1.5mm plastic strip.

That’s all for now. I burned through almost all my resin, so no more printing until Tuesday when another shipment arrives. No fit issues outside of my own printing mistakes. Lots of sanding and filling ahead, but this will be a fun one.