I’m wondering if the king tiger road wheels had any rubber (tires?) on the or was it just the metal hub touching the track?

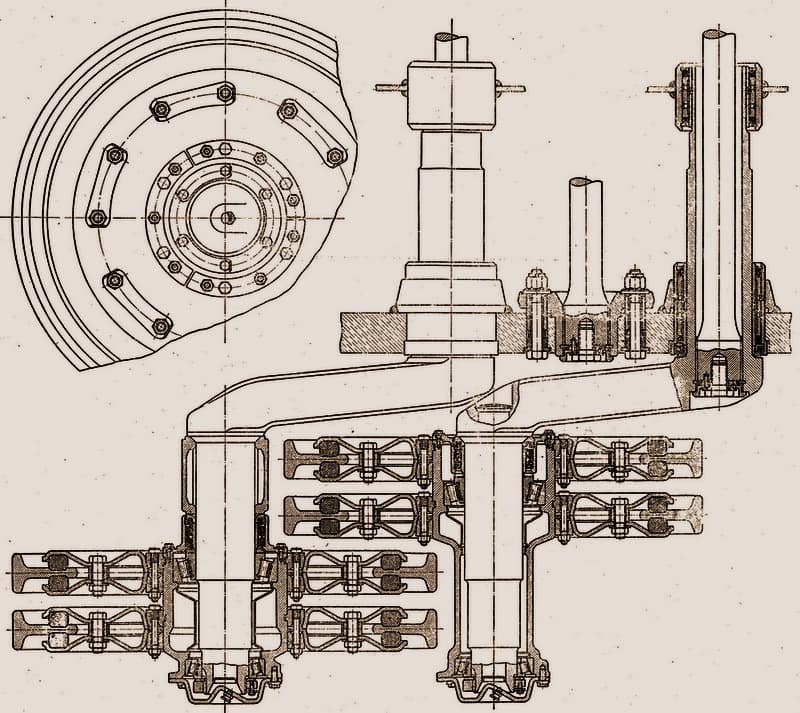

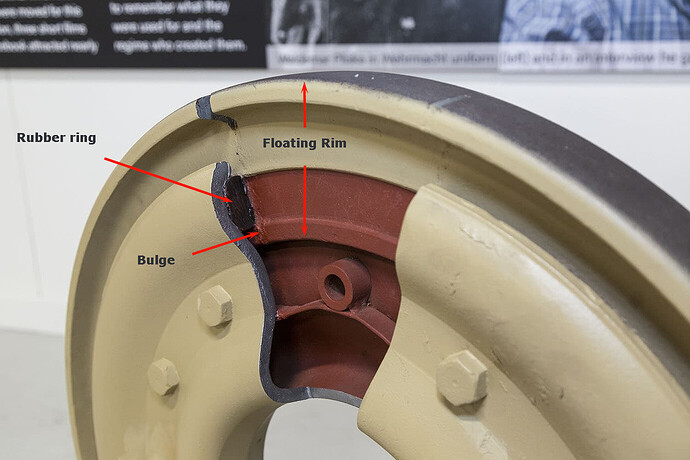

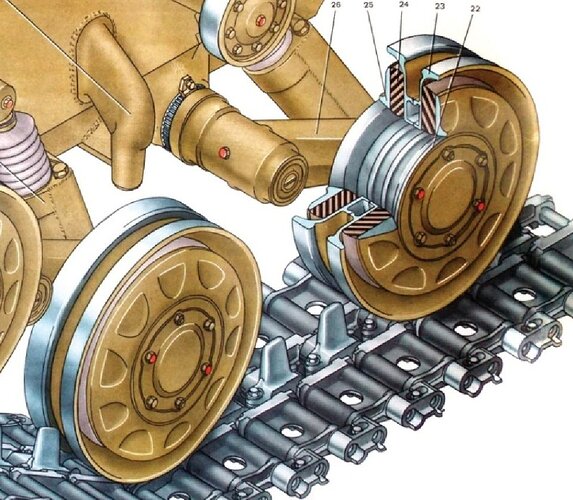

The Tiger II Road Wheel has a rubber ring sandwiched between the wheel halves, as seen in this cutaway. The outer edge of the rim is steel.

Hi! Not being a specialist on the King Tiger, I believe their road-wheels were all steel with no rubber on them apart from rubber cushioning inside the wheel that could not be seen without taking the wheels apart. So to the casual observer the wheels would look all steel.

The part of the wheel being steel which was in contact with the tracks whilst in motion, would be a dark steel colour but with bare steel colour on touch points.

Generally road-wheels were painted a solid dark yellow, dark green, or both, depending on the camouflage scheme being used.

Edit; of course @Paska gets in ahead of me! Fast work mate!

Do you know if the bushing the bolt passes through was larger in diameter than the bolt ? In other words, how does the rim “float” to cushion the ride ?

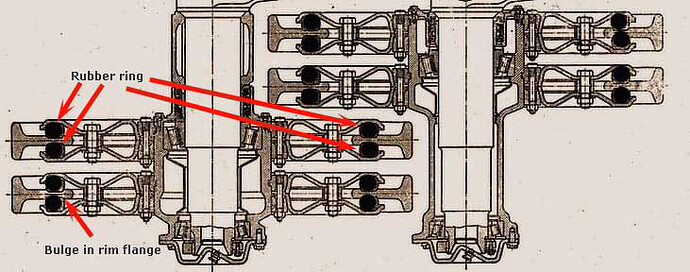

This cutaway illustrates the floating rim better.

The outer floating rim is trapped between the rubber rings, one on each side. The bulge on the inner most portion of the rim squeezes against the two rubber rings, preventing further movement in a radially outward direction, counteracting the inwardly directed forces from the opposite side of the wheel.

Thank you , shows it perfectly ! So the rubber rings are the only components holding the outer rims in place ? I would think over time they would fail and separate .

I cannot tell from those pictures what part is rubber! ![]()

This Russian system was preferred because the trapped tyres lasted longer than exposed outer tyres.

David

And this is a problem for a vehicle unlikely to survive a year, how? ![]()

I was thinking more along the lines of how they hold up on preserved vehicles.

Got it. Thanks.

Do you know if this design was used again after World War II?

It would be interesting to read a comparative study of this road wheel design versus others.

With noticeably a lot more rubber, though (for those lacking in German skills: Gummi = rubber).

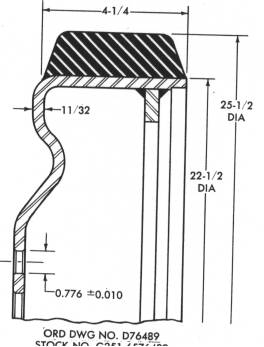

Over time, yes, but that time may be measured in years or thousands of miles of travel. I would bet that the rubber is vulcanized to the steel parts on one or both sides rather than just being a loose washer. The vulcanized joint would be about as strong as the joint between a normal roadwheel tire and the rim. (Some of those are molded over mechanical interlocking features but many are not, like this M24/M41 wheel.)

Also, we’re not looking at large deflections here; the center ring isn’t shifting an inch off axis. The movement is probably on the order of the compression of a normal solid rubber tire under load.

KL

It’s the same principle and practice as rubber-bushed track.

KL

The internal rubber inserts should be much more durable than external rim mounted road wheel tyres.

When you put weight on the road wheel with external rubber tyres, the compression stress on the Tyre would be focused on just the small contact patch between the tyre and track. The compression can get a lot more focused if some stones on other hard debris gets caught between tracks the road wheels. That’s why road wheel tyres usually show chunks torn out of its edges after just a few dozen miles of cross country travel.

If you put weight on road wheel with internal rubber inserts, the inset would be subject to the shear instead of compressive stress. But the shear stress would be distributed equally over the entire insert and focused on just one spot. Furthermore, you won;t have rocks or other hard debris taking bites out of the rubber insert.