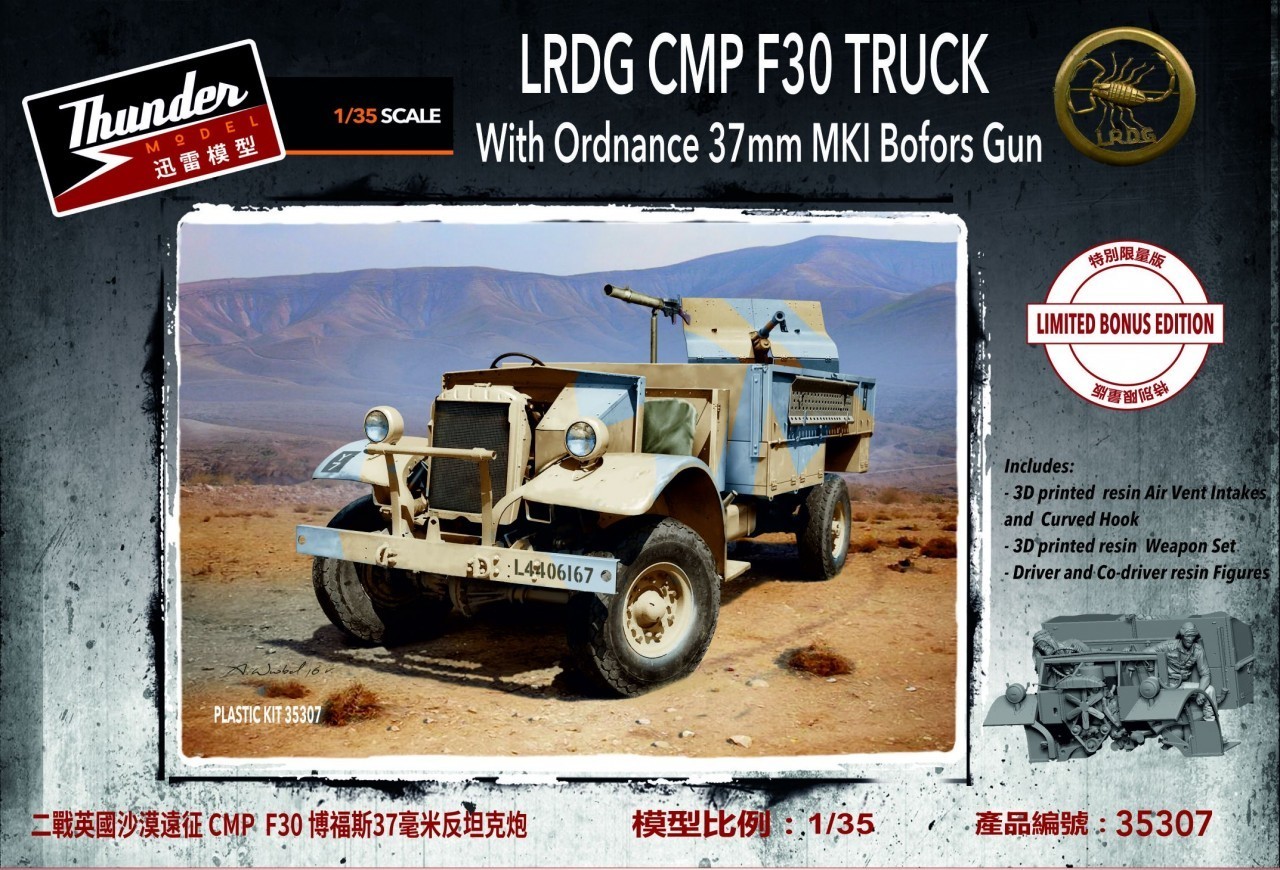

Bill Cross reviews Thunder Model's new LRDG CMP F30 Truck in a special limited bonus edition.

This is partial text from the full article (usually with photos) at https://armorama.com/news/lrdg-cmp-f30-truck

Bill Cross reviews Thunder Model's new LRDG CMP F30 Truck in a special limited bonus edition.

What’s the quality like on the 3D printed parts? Are they smooth and free of print lines and striations?

Not sure what everyone else thinks, but these part looks warped.

I recently spent a fair amount on 3D printed hatches, vision guards and light brackets for a Tamiya Early M4 (1/35), from a down under company. The quality looked fantastic, but the plastic was much too brittle and there was no good way to get them off the 3D sprue without a lot of damage. Lessoned learned… wait until things improve with this format. In the end, I ended up buying a Tamiya - Korean War, Easy 8 and cannibalising it. That ended up being easier, than using PE, cheaper than 3D (with postage) and I have a ton of useful spare parts, that I can use and share.

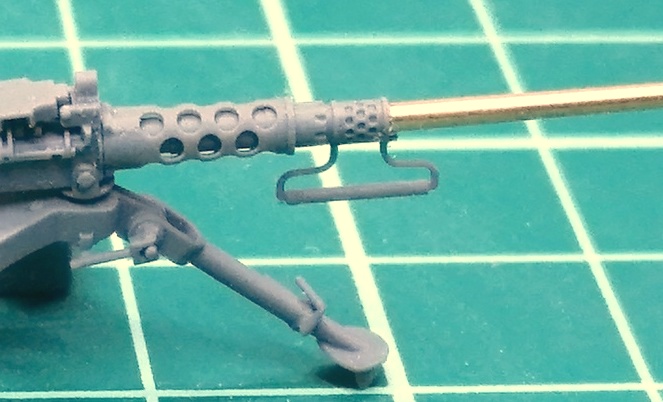

That depends on the resin used, my experience with T-Rex and Master is that they both use a more soft, flexible type without detail loss. And this is much easier to remove without breaking anything.

For example this Browning M2 delicate handle from Master was quickly removed without any damage:

As any resin parts, 3D printed or castings, they can warp and they can be straightened using hot water or a hairdryer and letting them cool at a flat surface

Recently, the LRDG has become one of my special interest subjects. Super stoked that T.M. is coming out with these subjects, especially as they look to be exceptional kits. Looking forward to building one of these.

Multi-media models are not for everyone, but dealing with warpage in 3D resin, legacy resin or styrene is part of modeling today. Libor is correct about how to manage it (he works for Thunder, so he know what he’s talking about).