Good point. I will give that a go.

Keep’n it on the square:

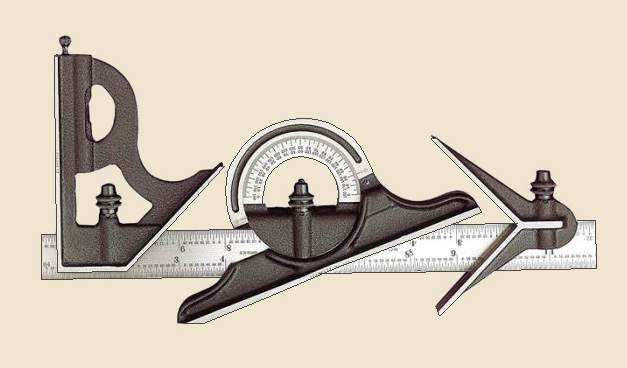

Some small machinist’s tools I picked up at various hobby shows that help keep my builds “on the square”.

I was extremely fortunate to inherit my Father’s “Starrett 435ME-300 Combination Square.”

My particular set is probably older than me! (72+)

(One set found selling just today on eBay - the bidding was up to $187.)

Stock Photo picked up on line.

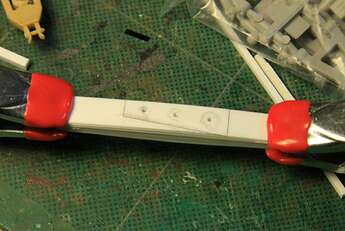

Something that also comes in handy from time to time are these miniature “Furniture Clamps”.

The beauty of these clamps is that unlike the spring tensioned variety (miniature welder’s clamps) you can keep these jaws perfectly parallel and square. Also those screw thread adjustments allow you to control the clamping pressure from “egg shell” gentle to bone crushingly firm.

These little ones I picked up at an old, OLD, traditional hardware store - but I have been using such clamps all my life, as I also inherited a set of four ~ 14", very large, all wood clamps of similar design from my Grandfather’s Upholstery Shop in Louisville.

Great S-B-S / How-To / BLOG! Thank you for sharing !

Totally OFF TOPIC here ! - - Just sharing for the heck of it!

- More “Tool Talk”-

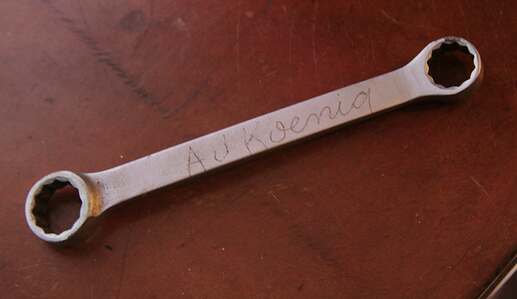

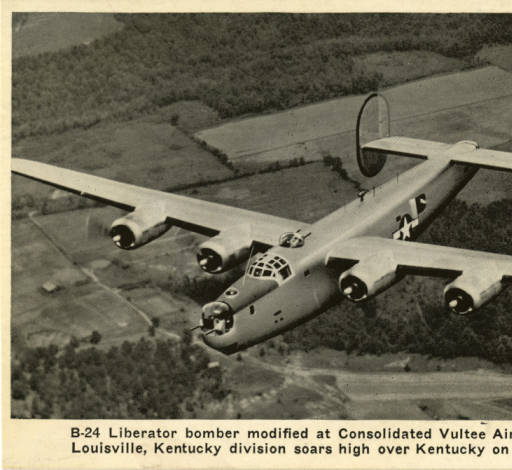

My Father was a defense worker during the war, doing alterations to B-24’s headed to the RAF. There was a Vultee Plant doing this work at Stanford Field in Louisville, KY.

I have also been extremely fortunate to have inherited my Father’s tool box from those wartime days. These tools have traveled with me (and been used daily) all my life! I even made a point of using them when doing volunteer restoration work at the Patton Museum and felt somewhat like a real defense worker - working on a 1940’s tank, with 1940’s tools and opening NOS parts boxes manufactured in the same era!

All Vultee workers where required to personalize their tools to prevent theft and also to identify exactly who it was that may have left loose tools in a combat aircraft after the refit. I therefore know that every engraved tool in my Father’s toolbox actually worked on B-24’s.

.

.

(B-24 “Dragon’s Tail” - Mike Koenig Photo)

Courier-Journal/Louisville Times News Photo

That’s awesome. My dad was a heavy pipefitter and worked at Fall River Shipyard in Quincy, Mass. during his early days. I have some of his tools as well. I cherish them and use them as often as I can.

That’s pretty cool.

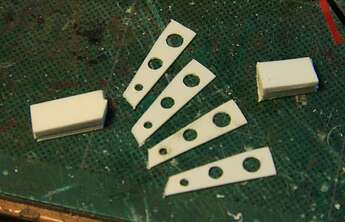

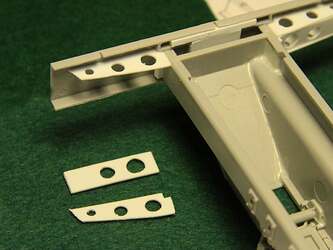

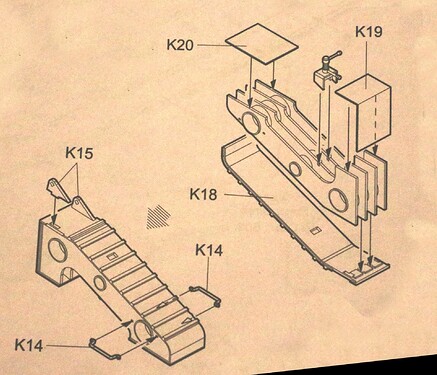

As I said before the “ladder trick” can work for other repetitive structure parts when needed, such as these bumper brackets needed for the MAZ-537.

Just stack the desired number of pieces and temporarily glue them together at the ends. Then drill and shape all the parts at once and finally, cut off the glued ends to separate the individual parts.

I always thought the “ladder technique” would be great if I ever needed to scratch build. for instance, the loading ramps for those big Russian 2 and 3 axle recovery trailers.

That is a great tutorial . Very informative and useful

Tank ~ That guy of yours clearly lost his head with excitement over you new ladder / railing!

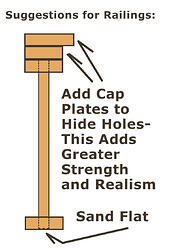

I am now using this technique to build some porch railings for an O scale rustic cabin I am working on.

Lots of “Nuln Oi” from Citadel, Black Shader applied to that roof. Also to the gray plastic “stone” chimney. Then the exterior walls got painted a far more “woodsy” Dark Green shade.

The railings are all just digital artwork for the moment but hopefully soon they will be real!

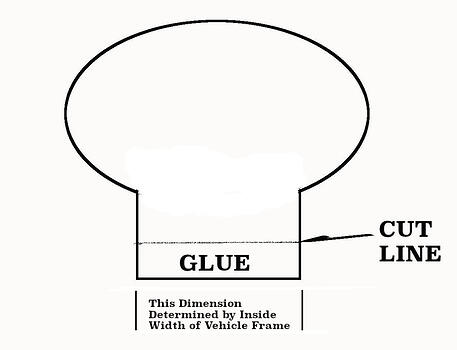

Hopefully I can stack eight railing cross members together and drill them all at the same time to make these “ladder” railings.

. Railing Cross-Section~ Anyone know who manufactured this structure kit originally? ~

I think it was originally intended as an S/O scale kit. (Plasticville Maybe???) I had some foam “stone” foundation material so I raised the entire structure 5/8 inch to bring it more into the O Scale World.

Those guys are not right in the head. ![]()

Splendid tutorial

Well Tank you seemed to have figured out how to get those guys to change their minds!

Very useful and informative thread. Thank you for sharing your knowledge and skills

Very useful and informative thread. Thank you for sharing your knowledge and skills

Have not had need of any more ladders or porch railings of late, but I am sure the time will come.

Mike

165thspc

Great tip on those

Just giving this thread a little bump.

Have not had reason to use this ladder technique in recent times.

GAZ-66 rear ladders and stairs:

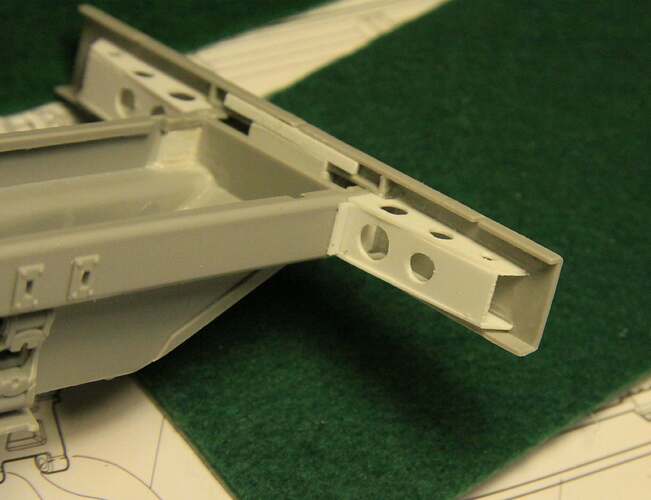

GAZ-34 kit bashed 6x6 still languishing as a shelf queen!

(No ladders here except the truck frame itself.)