Well for a change from lacing spoke wheels I have been building the chain over the last couple of days.

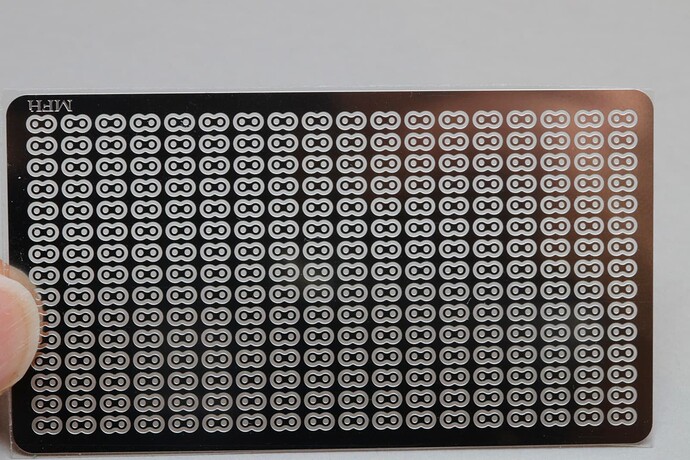

Components are a sheet of photo etch clips. The beauty of these, and the sheer relief, that they don’t need to be cut from the gate.

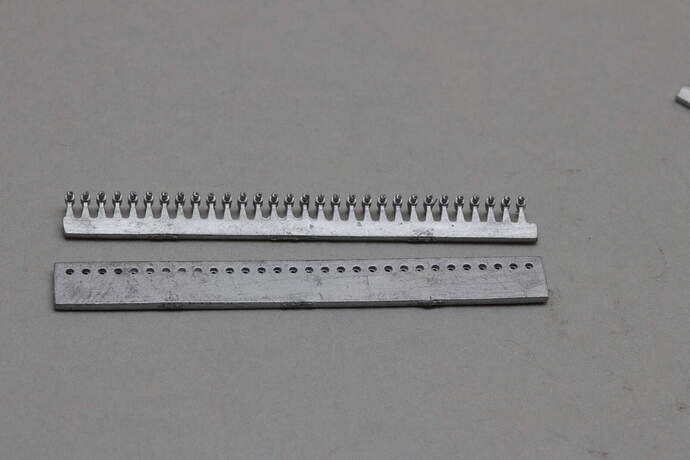

I don’t have a technical name for the other part of the links, but they’re in white metal and needed a quick clean up with a sharp blade. The metal flash flicks off with a knife.

and of a course a jig to keep them in place.

One side with its overlapping clips

both sides complete

I needed to do four in all, as the chain is 112 links.

You will have noticed at this stage the links are still attached to their “sprue”. This was the slowest part of the chain build, cleaning up the pieces. A sharp knife will remove the excess and round off the piece. (When building with white metal it is easy to cut with a #11 blade but you do go through a few of them)

And a section of chain completed

And completed. It is too long at present but when it comes time to fit I have some leeway for adjustments.

And back to the rear wheel for the weekend.

cheers

Michael