What is the best way to model this scattered around my mg 42?

I would just use styrene rod, cut to lenght and painted in brass to replicate spent casings; the MG34 and MG42 used a non-disintegrating sheet stamped metal link belt, so that could also be replicating using very thin styrene strip, coming from the ejection port of the weapon.

What he said if more than ~20 or so are needed. These are probably very nice bit at $12 for 25 casings on the expensive side in my opinion.

That’s like 48 cents a pop. a bit too step for my taste, especially in 1/35.

Oh, I agree completely.

100 rounds of those in the bottom of the ole 251 half track and your talking as much as the kit probably cost.

I might buy that if I could figure paint and place a few in a sniper vignette or similar.

I just chop up .020 thousandths (.51mm) brass rod to length. Passes the casual eyeball test. No painting required. Cheap.

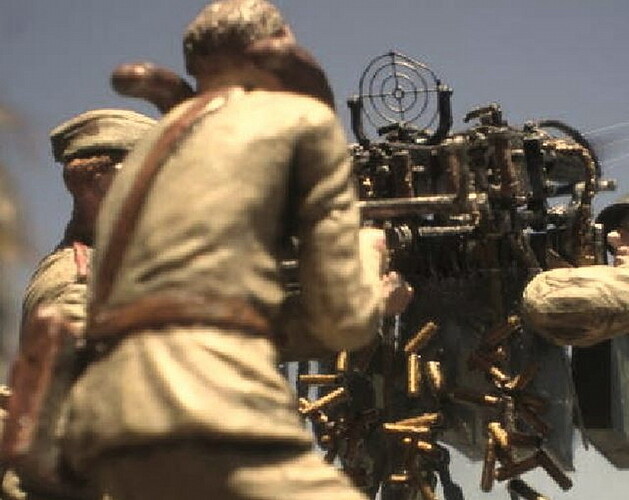

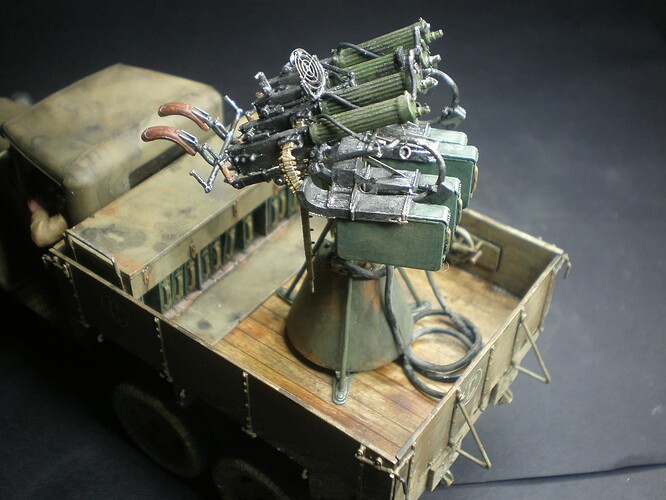

What the other guys have already said – and, if you want to represent something more dynamic…

That’s a Soviet quad .303 AA but the principle’s the same shell-wise – stick ‘em with cyano to super-clear super-thin acrylic panels cut so the edges are hidden by whatever surrounds them.

That’s a hell of a good looking gun sight and free falling shell casings!

A+++

Thanks Wade, from my more experimental phase when I tired of more passive scenes. It’s not perfect, one bad reflection and the jig’s up but under careful lighting conditions it can work in a display case.

How about a thin strip of Scotch Tape? It’s already sticky.

![]()

![]()

That works too.

It could work OK in some places. Depends if the tape adhesive’s strong enough to hold some shells end-on & at angles, yet without making the tape semi-opaque. I never found any but others might, it would make it a lot easier.

ok I got the .50mm brass rod , how do i cut it ?

I use my trusty Xuron 410 Micro-Shears. If you don’t like eyeballing the length, you can make a jig by poking a piece of rod through a scrap of Basswood strip and adjusting it to the proper length, then CA it in place. Drill a hole about 2mm away from it and poke the rod through, lining it up with the reference piece by using the nipper blade to square it up. Snip and repeat. Holding the jig in a vise helps.

If you have a scrap of Evergreen styrene flat bar the thickness of which is the length of the “shell casings” you want to make (or similar…wood would also work), drill a hole slightly larger than the brass rod you are using. Place the Evergreen on a flat surface with the hole facing up - this your “jig”. Push your wire rod in until it stops… cut… poke out the cut piece with the wire rod… repeat. All your shell casings will be the same length (more, or less). The reason for placing the Evergreen jig on a flat surface is so that the cut piece doesn’t go flying out and getting lost!

![]()

![]()

They also make a thing called the Chopper. Cuts brass very easily.

Granted…but it’s a lot more expensive!

![]()

![]()