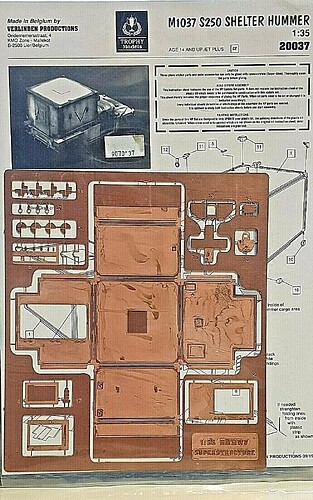

Verlinden made one back in the day that was full PE; you just folded it up and glu everything in place.

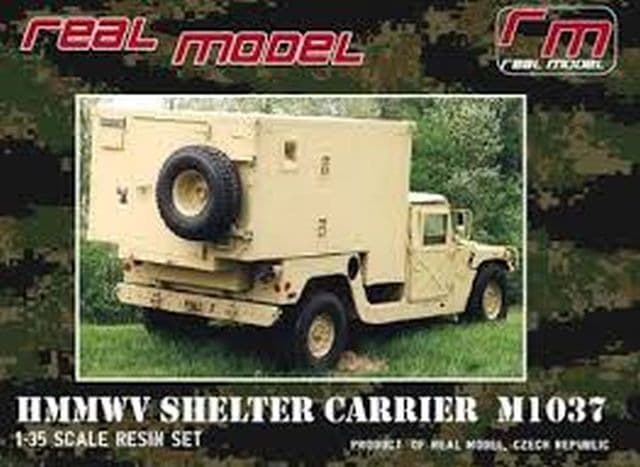

Real Model makes two versions.

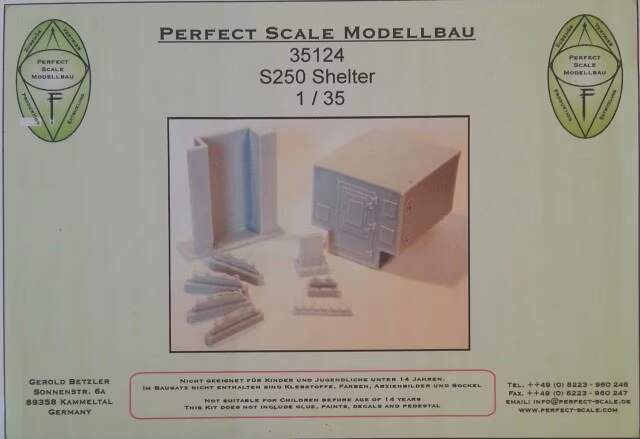

The square S-250 shelter, like the others above.

And the longer one which overhangs.

That sounds like pure hell. I’m not a pe fan most of the time ill take a plastic part. 3D printed is the way to go.

That 500,000 EUR number just for a mold making seems inaccurate to me or he added one more zero at the end.

See this article for some info: How to Estimate Injection Molding Cost? | Formlabs

The company I work for makes some complex multi-cavity steel molds for laboratory instruments. They must be made with precision to meet certain industry and regulatory standards. Making those molds costs around 100,000 USD.

Even if you account for the professional CAD engineer’s time, I doubt that it will go up as high as 500,000 USD.

A large industrial state-of-the-art injection molding machine costs around 100,000 USD: https://www.toolots.com/marketplace/seller/profile/konger92?srsltid=AfmBOop6ed69LWdWEyDRKnYXqyu-yqt46Q3Z18dVxK0itScG2I5s-yuA.

Even if you account for both the machine cost and design/manufacturing cost, it should not go up that much - especially if you’re outsourcing the mold design to China.

So I call Revell’s hearsay BS.

Oh; I totally agree. That kit is probably 90s vintage. Lonmg before 3D printing. But yeah; that’s high level work required to put it together.

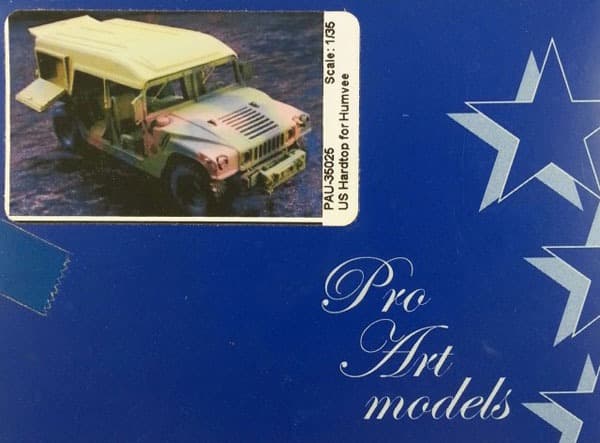

Pro Art Models made the Helmet Hardtop. I think it is long out of production. They do pop up on eBay from time to time though.

Pro Art Models PAU-35025

then all need is a LMTV cover kit

Second one is the one that I have.

Me too; I wish I’d known about the Plus version as those markings would be useful.

Just an uneducated guess here , but could the 500,000 EUR figure be for a full set of molds for a given kit ? 5 molds x 100,000 EUR per mold = 500,000 EUR . That figure does seem high, though.

No way. To make one mold for 1 sprue should not cost 100,000 EUR each.

For example, this entire instrument’s molds with complex compartments and multi-parts with precision to meet the FDA requirements do not exceed 500,000 EUR - no way just for the molds.

If Revell would spend that sort of money to roll out a new kit, something is very inefficient.

For instance, when Meng started, it churned out at least 10 kits back to back. So they invested 5 million USD from the gecko? I highly doubt the feasibility.

Plus, the cost of injection molding has come down quite significantly recently with the advancement of technology.

OK, so here’s an article I found Is Model Kit Making Expensive? – Model Kit Pro that states

"The CEO of Accurate Miniatures answered questions about the model making process and there were a few explanations about why models were becoming more expensive:That is why the average cost of a model kit is $30.00 or higher. The mold for a new release runs between $150,000 to $200,000. We use a more expensive type of mold, made of copper barilium, in order to enhance the details and improve the quality and fit of our part.”

“Our average run of kits for a new release is around 5,000“

200K USD v. 500K EUR - the latter number does seem a bit inflated.