Unboxing my BananaTank CATTB Abrams variant. I’l provide more context and history later, but I had to open the box!

The packaging was excellent: foam, bubble wrap, an inner and outer box, and well secures each component in an individual cell deep inside.

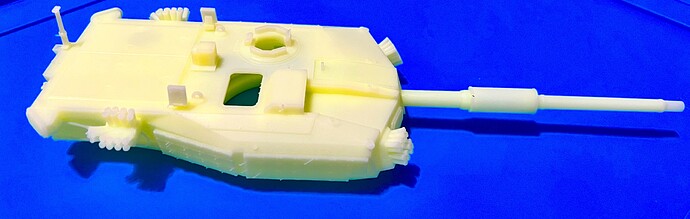

The resin is still banana green, appropriately, and seems smoother than my earlier AGDS. This is welcome, and a nice touch on the part of the printer. The hull appears to be a typical 1990s M1 hull and bitch plate.

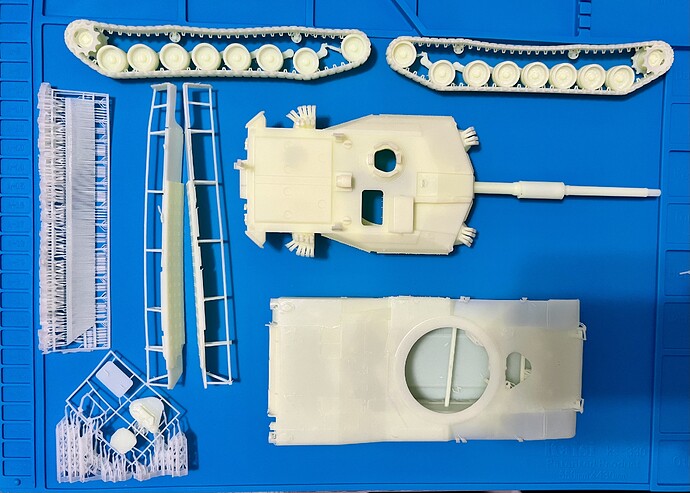

The total package is 11 major parts, with plenty of opportunity for making a nice vignette or diorama. I have a question which I’ll post later.

The running gear is a single piece for each side, and appears better-made than that on my AGDS. This is an artifact of 3DP printing I think.

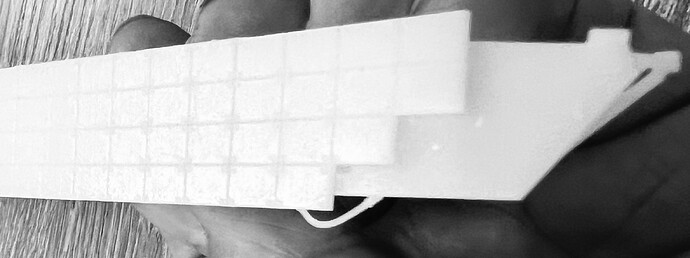

The skirts include a dust-reducing “hem” that hangs nearly to the ground. Think CR1 during ODS. This is made quite well, is very thin, and will be an interesting part of the project.

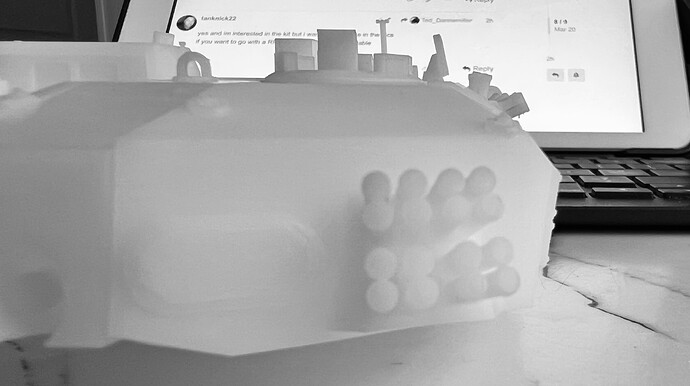

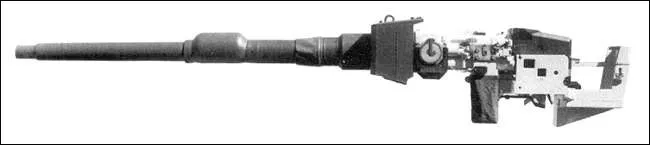

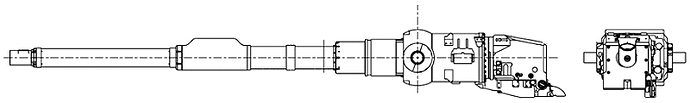

The turret is like a Leopard/Abrams mating that found steroids in the process. The corners all have a radar AESA radar transceiver. There are nearly seventy (did I count correctly?) dischargers that (so far) my research seems to indicate were a combination of as smoke for masking, and kinetics rounds to disable ATGMs (the threat was real in 1993).

The XM291 140mm gun uses an autoloader, and the gunner remains gun right while the TC is now gun left. The rotor is VERY deep. The GPS (Gunner’s Primary Sight) seems to sit lower in the turret, and has a long Leopard 2-like trough all the way to the turret cheek. On the roof, behind the TC and GNR positions, are sub-assemblies of the APS detection and kinetic kill system. The turret has the early style cross-wind sensor mast w/a T-top. The turret and hull skirts both have constructs that appear to be ERA or Composite armor over the base armor plate.

Overall, I’m very impressed. From Order to Delivery (Amazon: ADMIO is the seller) was only 9 days, including Customs!

@tanknick22 for the link!

This one will be my next step in modeling: preshading (vice marking panel lines after painting), modifying the 3DP resin assemblies, and creating a vignette or diorama. I’ve already asked a lot of questions here, and gotten lots of help. And I’ve watched a lot of FSM and similar videos!

More to follow. Questions and advice appreciated.