Well, first off, the research paper is clearly the result of a labor of love, with obvious great effort and time put into it. So, on that level, I salute you, sir, for going the distance and then sharing the result with us. Very impressive! Thank you!

Next, I believe that you are right in your observations to some of the posters here that there is a lot of information to internalize and consider. If nothing else, you have demonstrated and proven that “THE standard” was no such thing. There was a bewildering array of evolving standards that resulted in multiple different colors of paint being used in an overlapping manner at any given moment in time (although not all of them for every purpose and some of them only for very specific purposes). One might characterize this with the old saying, “Too many cooks spoil the pot…” A lesson in bureaucratic convolutions if ever there was one.

However, if a modeler is able to determine just which specification was in effect for the modeling project’s subject at the time it’s being depicted, there was certainly a definitive standard by which the prototype paint was manufactured to satisfy. A definitive color standard was applicable and possible to provide to both the paint and end-item manufacturers.

That there were multiple different standard colors of “OD” available in the field which could be used in overlapping ways by different end users is also made very clear. A factory painted vehicle in the contract specified color only remained in that color until someone in the field or depot painted it in a different color or colors. Yet even those colors were manufactured to standard (exacting as the tolerances of that standard allowed).

I also believe that given the documented scientific exactitude (its history and employment) to which any specific color of any paint could be accurately measured and therefore manufactured to standard, this paper does a lot to mitigate the validity of the argument that "anything goes. The color measuring technology was mature, long standing and widely available. The argument that, “Enforcing the color standards was simply not possible or practical” is just not historically accurate or valid. Latitude within the standard made by the applicable governing bureaucracy may have been allowed, but variation would have been accepted only within the limits or tolerances of that standard. A standard with no tolerance for variation would have been expected to match that standard or it would not have been accepted (or even manufactured, since the paint makers would have had access to the same measuring technology).

My first read did leave me a question regarding the change of the standard factory

ES474/680 lusterless / OD319 to OD 108 semigloss:

Why? What was the reason for this change just BEFORE the end of the war? The change was made before the surrender of the Japanese. The war was still on going and the invasion of the Japanese home islands still possible, so presumably the use of OD 108 semigloss in combat was envisioned. Why was it then considered suitable for use in combat before the end of WWII while clearly the War in Korea demanded a return to a lusterless color. I understand that the main focus of your research was on the colors and standards, themselves, and not necessarily on the reasons and thinking behind them, but I wonder if you learned a reason for this this ALMOST end-of-the-war change?

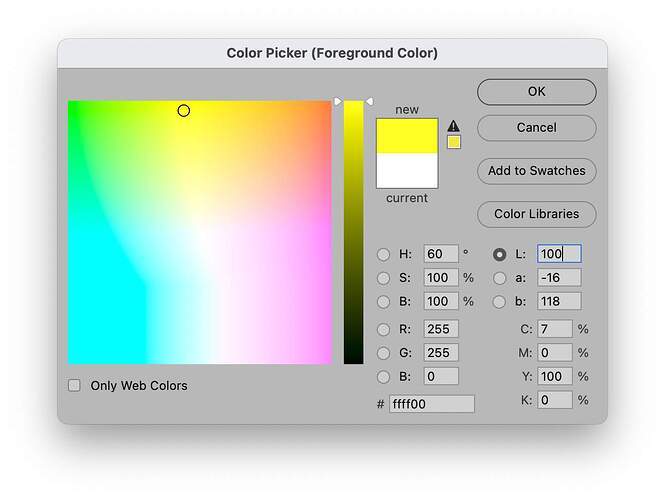

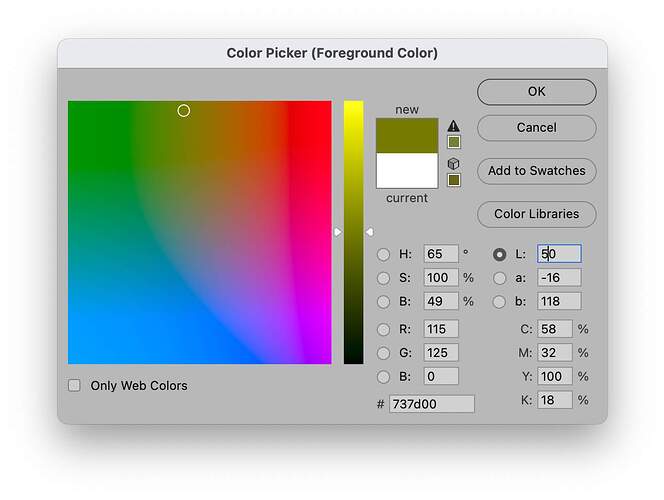

Finally, I suppose the debate about the validity (or lack) of the concept of “scale color” or “scale distance” will continue even after this work. The “factory color” standard may be fairly certain and fixed (in hue, chroma and value), but the perception of value and saturation of that color as influenced by distance, atmospheric interference and other effects on the light reflected from the object to the viewer would still seem to be major considerations for the scale modeler.

:max_bytes(150000):strip_icc()/the-visible-light-spectrum-2699036_FINAL2-c0b0ee6f82764efdb62a1af9b9525050.png)