When you get a better idea of exactly what you want, let me know. If you have any sort of artwork in digital form, that will help. The prices I listed for the “U of P” tumblers would probably change for a different design.

With custom designs there’s a per-hour shop rate just for the design work to turn the art into a usable stencil (which then has to be tested) or maybe a laser cut file (again, with iterations of testing). How many hours they’ll charge just depends, but they’ll quote it out first before you accept or decline the quote.

(The “U of P” design is already done, so we now consider it “standard,” and the stencil surcharge just covers the materials, cutting, and application. It’s also simple enough to do with stencils and Cerakote. More complex designs with lots of fine detail are usually better to do with the laser or some combination of laser and Cerakote. Custom designs just require additional work.)

I’ll search my files to see if I have a usable SF crest. I know I don’t have the “Freddy” drawing, though. I’m not the “laser guy” (who’s actually a girl), so that kind of work is whole 'nuther level with regards to getting the work done. If it’s just Cerakoting, I can handle that “in house” at my own shop.

I actually have a Type 07 FFL and my own gunsmithing shop. I work out of it as both an independent smith as well as an employee of the range. For range work, the firearms are transferred from the boss’s FFL to mine, and I take custody of the gun and do the work at my own shop. I also take in work directly from my own customers. I do the Cerakoting (and other work in my own shop), but any laser engraving is done at the range by other employees. If I need laser engraving for one of my own customers, I send that job to the range, again, transferring it from my FFL to the boss’s (if it’s a firearm).

(I’m retired and don’t do any of this fulltime to pay the bills. The cost of the laser engraver is not something I have any interest in. The range where I also work parttime is, of course, a “real” business, so the capital costs of the laser engraving works for them.)

We both work off the same pricing and shop rates, so the costs for any work, whether or not I do it in my shop, the work’s done at the range, or it’s a split job, are the same for the customer. I don’t undercut the boss because I’m not a competitor, per se. I have all the smithing work I want and am happy to let the boss deal with the vast majority of the business-admin crap of trying to make serious money to pay her bills (and keep everyone else who works there employed).

Anyway, long explanation so you have a better idea of “who’s who in the zoo” here.

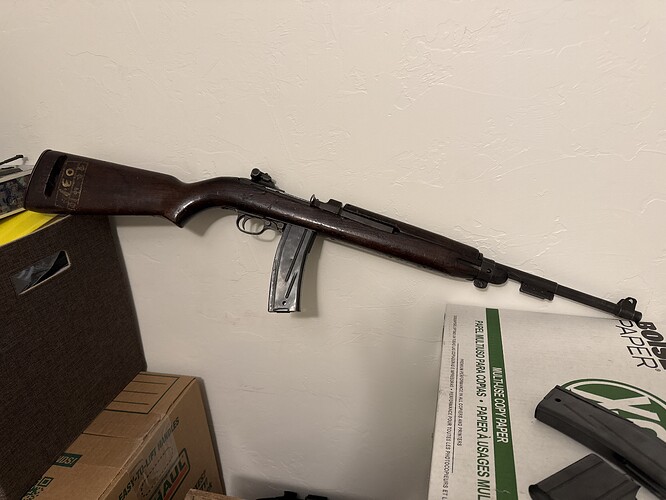

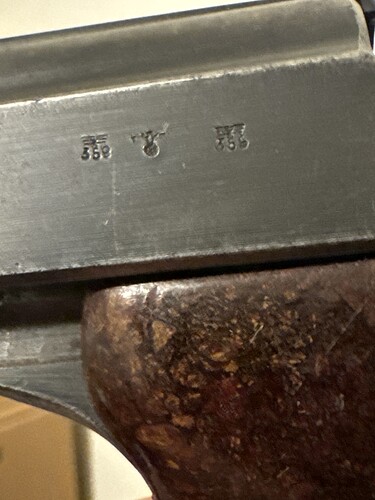

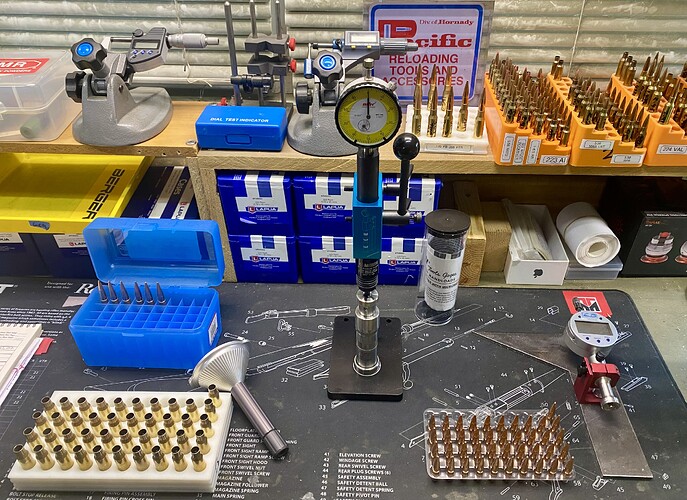

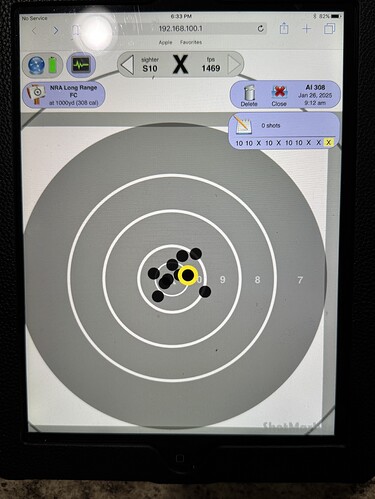

Here’s a project that came out of my shop. A fully National Match conditioned LRB Arms SA14 (glass bedded, unitized gas cylinder, etc.) with a Criterion medium weight match barrel.

Any hoo… I mostly just work on the ones that I find interesting.