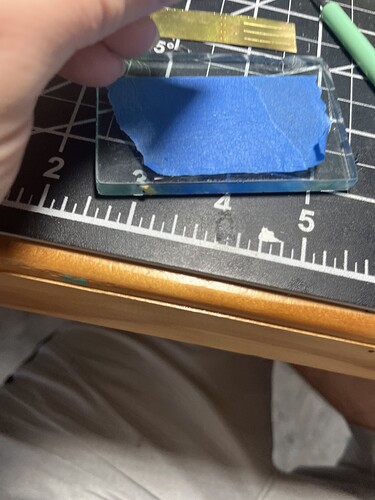

I am working on the Tamiya Cromwell. I got voyager fenders for it. These require you to emboss some bolt head detail and strengthening ribs along the length. Embossing the ribs induces some stress on the parts that has resulted fenders that are slightly concave.

Any idea how to get rid of this? I did try bending it back. But due to the close proximity of the ribs this causes it to snap into a convex shape, as if there is now some springiness to the metal. A small amount of pressure and it snaps back to concave. Perhaps annelaing?

1 Like

Annealing might have worked before embossing…

What I usualy do when this happens is -

I place the part on hard surface with the embossed side up and I run one of the embossing blades from my Excell Embossing tool set(#30605) along both sides of each embossed line.

This not only negates curvity, but also highlights embossed lines.

HTH!

Cheers,

Angel

6 Likes

Well…. Annealing before would have been smart lol

2 Likes

Can you use CA to glue a large plate of styrene underneath?

1 Like

Wow, I ran a small nail down the edge of the embossed detail. I am shocked how well this worked, it took a lot of the stress out. Neat trick! Thanks for sharing

4 Likes