Hi all, I’m thinking about beginning my Rye Field M1A1 Abrams, 1991 tank, 1/35 scale. The kit has the older style ‘chevron’ tracks, with link and length pieces, the long, straight pieces being a solid item, with just the need to add the center guides, which are separate pieces. I am not thrilled with these tracks, but I think I CAN make them work. The individual track links that are provided are meant to ‘wrap around’ the road wheels and drive sprockets, where necessary, and then have the end links of those curved sections glue onto the long, straight sections. While not ideal, these individual links can work, as long as the end pieces and center sections (where the track guide horns mount) are adequately ‘bent’, so that the link end pieces, when wrapped around a road wheel or drive sprocket, are perpendicular to the center of the wheel or sprocket. In order to do this, the individual links need to be ‘bent’ somewhat, the ends and center parts need to be bent the same amount and in the same direction so they look 'correct; when wrapping around the wheel or sprocket. The only challenge is making sure that the end and center parts don’t break while bending them, so care must be taken when doing this. I hope I’ve explained this adequately, and I’m curious how many others of you have done this same thing for this kit, or plan to when they build it. My other alternative, which is much more expensive, is to buy the TRex set of fully articulating tracks, the M1 Abrams T-156 Chevron tracks, which will make each link in the entire track fully articulating. I actually have the TRex set, just in case I need it. Is anyone else planning to go to this level of detail to make their tracks look as realistic as possible?

Looking at the kit instructions, the only potential problem I see is center guides. Where the track placement could not be in the same location each time. Good news, only from the outside would one know for the tightest turn. The guides in that location would not be visible, so at most (around the sprocket) just having something would be enough.

I am working them right now, but on a Panda M1. I tried the TRex tracks, and gave up. They are very time consuming and over engineered (imho)-and not cheap. I plan to do a lot of dry fitting to make sure they fit the drive sprocket cleanly so the shoe pitch is correct. I think the same approach will work with getting them to fit and curve, trick is to not shave off to much contact area so you have some fit tension.

I will post some pictures when I get to that point, almost done with assembly and initial painting.

Cheers

Bret

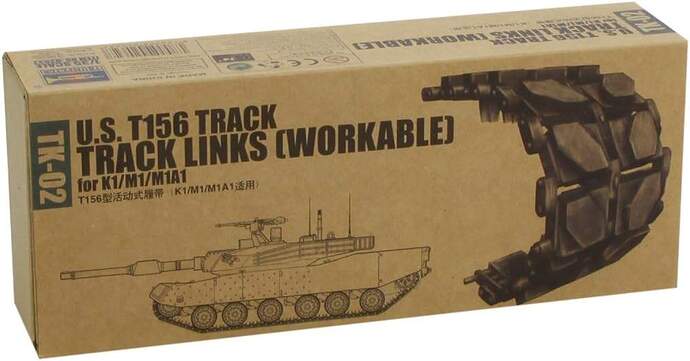

Another option is the Trumpeter indi-link T156 tracks. They are like AFV Club tracks where each one is a separate, one-piece track block, including the guide teeth.

I agree that the TRex tracks are way overdone, and would take a HUGE amount of time to complete. I would love to see what yours look like when completed! Thanks a bunch.

Thanks, Gino, I didn’t know another option was available. I appreciate the heads-up!

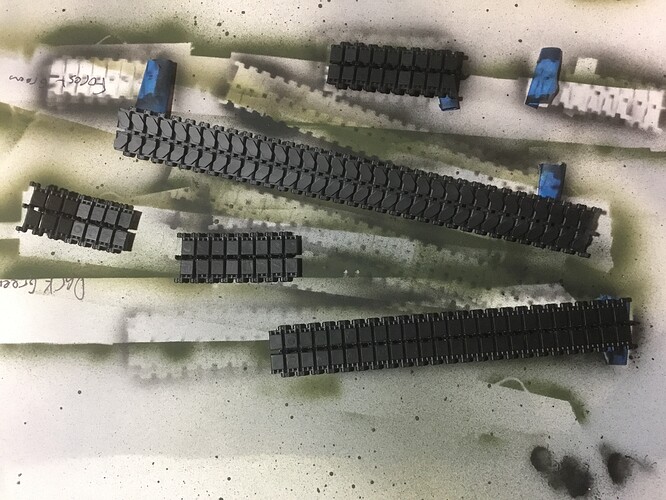

Just one side worth, primered. The short runs are the single shoes, not glued together just stuck with click pressure for painting.

I will keep them separated so I have equal counts.

Have to get the road wheels finished this weekend and on the hull, then I can work the fit for the sections around the idler and front road wheel. I have not yet decided how I am going to work those sections.

I also have to fit on the drive sprocket retaining ring once the shoes are in place, I have not checked the fit there either. Fun.

Did some basic weathering on the tracks. Just getting some dust/dirt on the end connectors and mid sections. Will have to finish after doing the final gluing in place.

just doing some dry fitting. TBH I may leave off the top run. It will not be viewable under the side skirts. Doing this will actually make fitting around the drive sprocket a bit easier.

Had to do some paint scraping on the road wheel arms to ensure fit for the road wheels.

Have gotten some glue on the front run and got them bent around the front road wheel.

2nd picture is my attempt to put a spacer in the drive sprocket so it will fit the width of the RFM tracks. I will have to do some clean up of the card stock. Had I known this was my path -I would have held on the assembly of the drive sprocket. But here I am.