I have my own home made box similar to yours. I’m using a cooling fan for rack mounted computer components that I just mounted opposite to draw air thru the filter. A place I worked out did custom home theater, alarm and smart home systems. I bet you can find one on the cheap at some off stores that sell old computer equipment, the diameter of that cooling fan was about the same as dryer hose like the fellow above used. Plus since they are designed for rack component pieces that generate a lot of heat they really move some air.

I got this back in the 90s, Testors label. Don’t recall the fan power but when using spray cans I have to watch how much is being sprayed, the fan is fine for stuff coming at it but cans can put out a volume the fan can’t get all at once. It works well enough but for big priming jobs like terrain I go outside. The fan is strong enough to blow up and then 10’ to outside. I have a dryer outside vent in my exterior wall, put that in month after we bought the house. There was a site that had the calculations for how much h power a fan needs to go a distance including bends.

What are the dimensions of your booth, @SableLiger ? Is it built out of just regular foam core board or did you waterproof it somehow?

The dimensions are 20 1/2 inches wide by 15 inches tall and 15 inches deep at the base and 8 inches deep at the top.

I used 1/4 inch thick foam board from Hobby Lobby and it is not waterproof or anything. Then I cut an opening in the back for a standard 12” by 12” home air filter from ACE Hardware and put it together using Frog Tape, which is pretty strong.

Thanks @SableLiger , what kind of fan do you have hiding in the back? Im building a spray booth this week (finally) about the same size. I have two pc radiator high static pressure fans to go into mine.

None yet. But I’ll try to find a PC cooling fan.

I got these: NZXT AER P - RF-AP140-FP - 140mm - Winglet Designed Fan Blades - Fluid Dynamic Bearings - PWM Static Pressure Fans. Together they’re rated for about 240 cfm and they’re super quiet. Adding an old power supply from an external hard drive to mine. Will set them behind the filter.

I did the same, with 4 fans* from a rack mounted computer components mounted in a custom laser cut frame, a dryer hose, some filter fleece, and a lot of duct/gaffer tape.

Total cost under UKP£1.60/USD$2.00 for the fleece.

- 4 fans was waay too much, I run with 2 disconnected.

jared how did you attach the fan to the back of the booth and how did you power it? those fans don’t come with a plug in wire and on/off switch.

thanks, Joe

I used zip ties pulled from the outside in through the fan guard and the corrugated sheet through the fan screw hole. Two ties per hole the heads are big enough to not pull through and another tie (head only on the inside to secure it all.

Inside before trimming the zip ties:

Outside:

To power the fans, I have a 2 amp 12v power supply with a Molex connector to power hard drives similar to this one.

I modified a Molex plug to a dual fan connector cable (3 pin - the fan PWM connectors are not used) to go to the ground and the 12v rail of the power supply. The 5v rail is not used. The fans run at full speed all the time. I just tucked the power supply inside below the fans in the plenum behind the filter.

Right now, there is no power switch. Round two will include an inline switch in the power cable.

I also have led undercabinet light bars that are USB powered. Future upgrade will tap into the 5v rail for power instead of a USB wall tap when I build/find an appropriate connector cable.

excuse my ignorance, i’m not familiar with the terms. what is a rail 12v 5v, or a molex plug.

Joe

Those are the power circuits on a PC power supply. Different levels go to different ‘rails’ to power the different components inside the case. Molex is the name for the plug used in these sockets. In the pic above it is the end with the 4 little openings next to the bigger block.

do these fans come wired and with connectors?

The fans have a 3 pin “motherboard header” plug. One pin is ground, an other is power (12v), and the third is the PWM signal wire which allows software to control the fan speed when plugged in to a computer motherboard. That pin is not used in this case. I had to buy a fan connector to Molex cable. This cable has a connector on one side that is the fan and the other goes to the power supply. I had to move the 5v pin to the 12v pin on the power supply end to run the fans at full power.

And @brekinapez is correct the rails are the power circuits inside the power supply. In a regular computer power supply there are different tracts the power goes through to supply different components in a computer. Some run at 12 volts and others run at 5 volts. That is the reason for all the different power connectors inside a computer tower.

In my use case here, I want the fans (which are 12 volt fans) to run at full power all the time so I powered them via the 12 v connector on the Molex cable. In the picture of the power supply above, the 4 holes (three with gold contacts) are left to right 12 v, 5 v, Ground (in this plug its blank - no gold terminal) and Ground. Ground is typically common between the 12 and 5 volt circuits so to save a penny or two they only had one of the ground ports used.

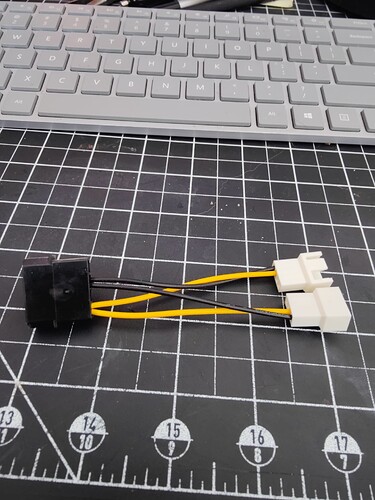

This is the fan connector I used (modified). The White connectors go to the fans and the Black to the power supply. the Yellow wires are power (12 v) and the Black are the ground. What is no longer there is a Red wire for 5 volts. Yes, I cut the red wire! ![]()

![]()

I hope that helps. Feel free to PM me and I’ll help you find the right components to build yours.

I probably have the components if you don’t mind them being 15-20 years old.

If you have an old power supply, fans and cables from a computer you could do it. This little one was just handy and much smaller.

Not far off a year since I bought the giant atex fan, I finally tried it out. With it parked in the window sill so the back is out the window, I just used my mini photo background box to catch overspray. No ducting or filter yet, but it’s so powerful it just took everything away - though I was able to paint… it didn’t just suck all the paint away.

Once I get a bigger desk I’ll probably make a booth with a hole in the back to line up with the fan, but I think with it sitting in the open window there’s no need for ducting. Not sure if there’s really any need for a fleece filter even. A little cold in the winter having the window open, but not as bad as it used to be painting in the garage.

i have an old gateway tower unit i no longer use. it is sitting on the floor of my basement. could i remove the fan from that?

Joe

@Bomber14 You could try it, but it might not be strong enough. Most PC fans aren’t that strong as they are made to just move air unimpeded by obstructions. That’s why I got the high static pressure fans. They are made to push air through an obstruction like a radiator for liquid cooling a CPU. The fans I use move about 120 cfm each whereas most 80mm pc fans move closer to 25 cfm each.

So, you would need around 10 80mm fans to move the same amount of air as my two 140mm high static pressure fans. Probably more because the filter medium will impede the airflow and normal pc fans aren’t meant to push through obstructions.

By way of comparison, the orange fan in my photo moves around 900cfm.