Hi

do You have any good pictures or knowledge how smooth was surface of german tanks armour (rolled steel)? many modellers are making it with putty+glue and it looks great, but I’m not sure, if it’s correct. of course, there are Panzer that are still in museums today, but isn’t this surface just corroded after 80 years?

Mannet, welcome to the forum! We’re happy to have you on board ![]() .

.

I think the question when it’s asked seriously has several factors to consider.

1) What’s technically correct vs what looks correct.

Having climbed around on a real Panzer IV many years ago and spent some time with other Panzers, I find no fault in subtle texturing.

The problems start when the putty texture is heavy and not gone over with sandpaper ~600 grit etc.

Occasionly, adding very thin putty texture can tone down excessive molded in texture.

2) Age of the kit

Flat open plate tends to look boring when painted. This is especially egregious on older kits before any texture was molded into the plastic.

3) What’s the modeler really doing ![]()

Some modelers will call it texture but often its a thin coat, thin as paint that’s being flowed around small parts, especially PE parts to fully integrate with the model.

Both of these models have subtle texture applied with thin as paint putty.

FWIW - My preferred method is ~80% to 90% liquid cement with ~20% to 10% putty.

The slight additional texture from this lays ground work for the weathering to pop.

YMMV - there’s not a wrong or right way just what makes you happy with the model!

Cheers ![]()

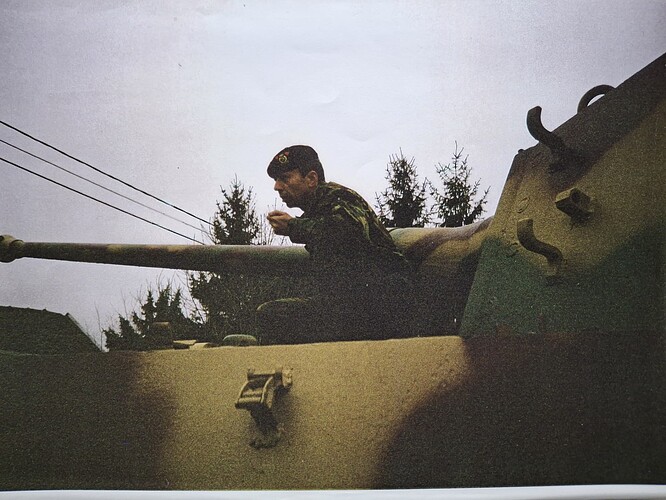

Oh my God! The La Gleize King Tiger! I know it so well - back when (I’m not even sure when) but I ended up lecturing on its characteristics as part of a battlefield study of the Ardennes campaign. I mean, what a privilege - and here I am folks (in this rather murky pic):

God, I was top of my bastard game back then!

Meanwhile, back to rolled armour plate - sorry about that.

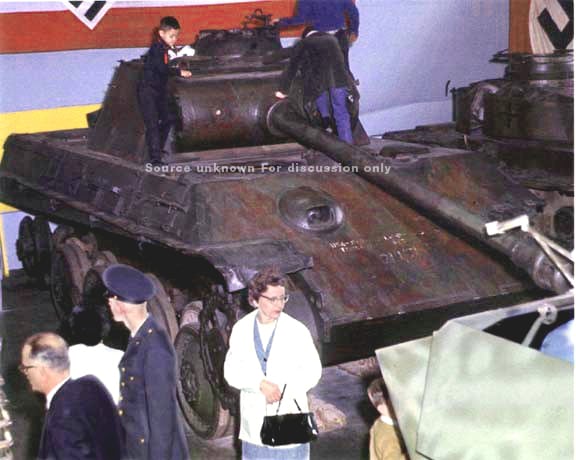

hi, thanks foe answers ![]() on this photo surface is looking irregular at strange amazing way XD

on this photo surface is looking irregular at strange amazing way XD

but isn’t this corrosion damage? or old paind under next layer?

That’s what I was going to say: you don’t know what happened to the surface between the tank leaving the factory and this photo having been taken.

Peened away the rust and some surrounding paint and then painted over.

I think that the surface of those plates from the factory is smooth.

The matt paint we apply to our scale models has a coarser surface

than the scaled down “armour” plate.

Rolled plate was smooth even a hundred years ago,

check any old Ford model T or other car from before WW II.

The scales that form on the surface during the rolling process

(basically when hot metal is shaped) needs to be removed to

avoid manufacturing problems.

Cast metal parts, especially if cast in sand, will often have more texture.

Applying a cast texture to rolled plate is somewhat “odd”, at least in my opinion.

Notice the surface closest to the impact location is smoother. That area had no paint on it before the tank was repainted. That paint had been knocked loose during the impact. The oval shape around the impact leads me to think the surrounding surface on the front had paint and the paint was failing when it was pressure washed and repainted.

I’ve been thinking some modelers tend to overdo the textured rolled plate and weld seams.

It’s a bit of a fashion such as the brightly colored three-color camo lime green, cream, and red panzer models.

Yeah modeling fads come and go, and everyone wants to do the latest and greatest. I’ve been up against the Littlefield Panther and Hetzer at the National Heritage Museum and the armor is smooth to the touch. Certainly nothing that would show in 1\35 scale.

Was it the RFM Panther F that had such “texture” it looked like a minivan left out in a golfball-sized hailstorm?

I can’t get past that.

The problem with using the La Gleize Tiger as a reference is a) it has been standing outside for 80 odd years, b) it has been “restored” several times including the fitment of a Panther gun tube to replace the damaged one.

well… I found grat photos of PzKpfw III from Deutsches Panzermuseum:

as for me armour surface is definitely not smooth, but still - what is corrosion damage or old paint and what is steel surface…

I’m hope to visit Munster in june and see those tanks in real life ![]()

Does anybody know if armor plates were (at least in Germany) rolled hot or cold ?

Just got to say folks, I visited the Tank Museum at Bovington yesterday- checked out the armour plate on the German exhibits: smooth as a baby’s bum!

Armor is surprisingly resistant to corrosion. Unless the tank has been submerged in a marine environment the surface will look pretty much as it did when the tank was assembled.

KL

Key points to consider:

-

Surface finish:

- Smooth (cold-rolled): Generally used when precise dimensions and a clean, smooth surface are needed, like in machinery parts or sheet metal fabrication.

- Textured (hot-rolled): Commonly used in construction applications where added grip is desired, like floor plates or bridge decks.

-

Strength and cost:

- Cold-rolled: Offers higher strength due to the cold working process but is usually more expensive.

- Hot-rolled: Less expensive and suitable for structural applications where a rough surface is acceptable.

To illustrate:

This is what a Sherman’s armour plate looks like after having stood literally by the sea for sixty years, with really no more than occasional paint jobs and one major overhaul (25 years before) to protect it for most of that time. This picture was taken after it had been stripped bare and repainted, with no filler used at all — the pitting you can see is scars from where welded-on things were cut off with a blowtorch in the 1950s. And this is the side that always faced the worst of the North Sea winter storms.

For comparison, the track that had been put onto this tank when it was fixed up about 25 years earlier:

I would say that all armor plates on German tanks were hot rolled, descaled, and pickled. Given the heating and quenching processes that armor must go through after rolling to thickness there would be no point in expending the extra effort in cold finishing.

The reference to a “textured” finish above is irrelevant in this case (or any armor that I’m aware of); It’s referring to an embossed finish like diamond tread plate.

KL

A no brainer. Cold rolled steel is only millimeters thick, not centimeters or more. A quick trip to my garage where I have how rolled steel stored can shed more light. As can an analysis of photos already on this thread, but I’ve got other things to do right now.