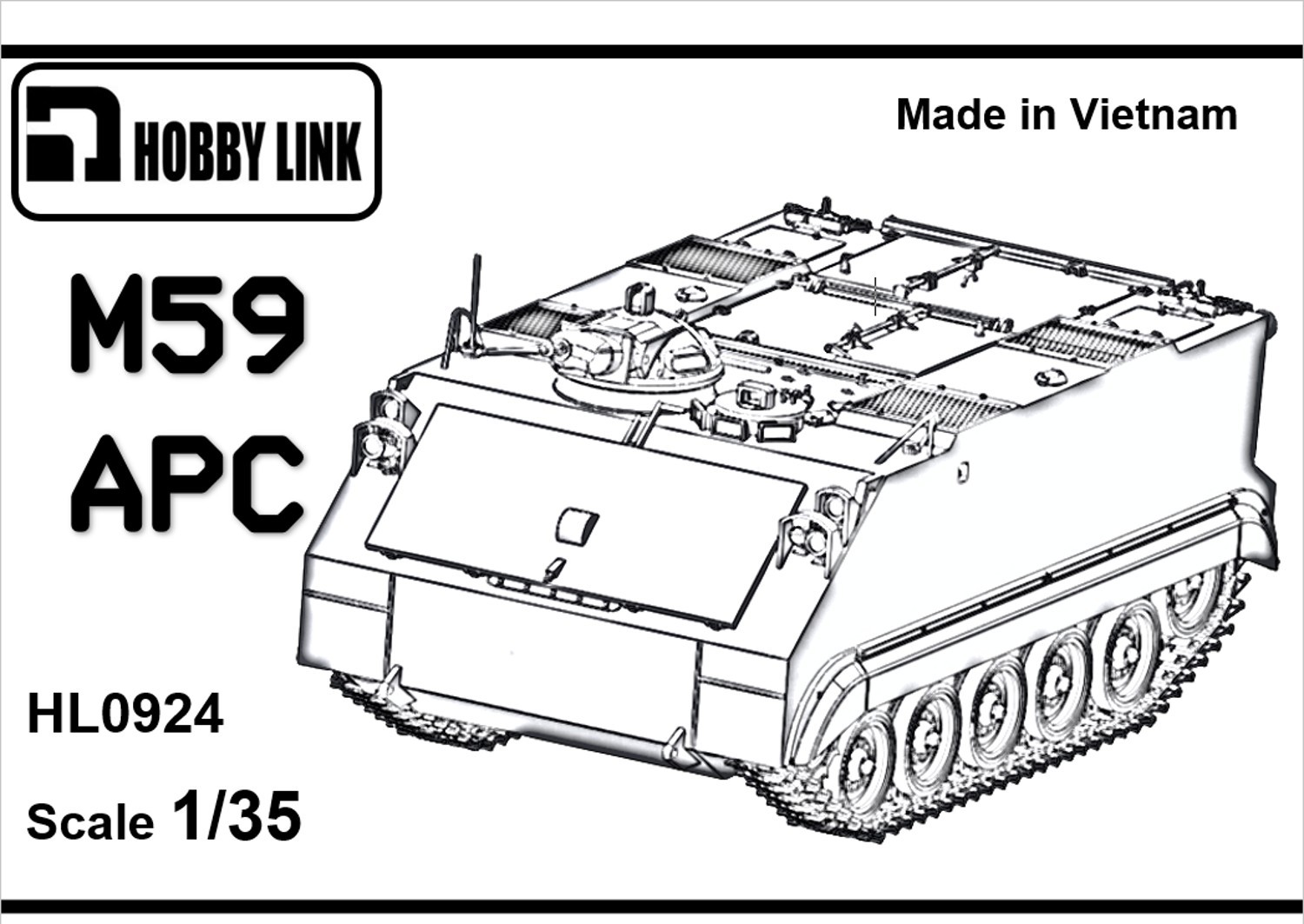

Bill Cross reviews Hobby Link's impressive new 3D-printed 1/35th scale M59 APC.

This is partial text from the full article (usually with photos) at https://armorama.com/news/hobby-link-s-m59-apc

Bill Cross reviews Hobby Link's impressive new 3D-printed 1/35th scale M59 APC.

I started my M59 last week, and the only real issue has been trying to correct the warpage present at the lower edge of the hull sides. I believe this is due to the complexity in getting such a large piece printed. My efforts in using hot water have not been successful, but I have not been using boiling water, due to having ruined plastic parts previously that needed correcting.

Those are good points about how to deal with warpage and lines.

Some modelers I know prefer to use a hair dryer rather than hot water.

Count me among them.

In this case, considering that the side is a flat sheet, I would cut a new side from sheet styrene.

Heat generally doesn’t work so well on 3D printed parts that are created in DLP (i.e. “resin”) printers. The resins used are cured using UV light and the resulting solids are not thermoformed nor urethane plastics. The time to correct deformities is during the post-printing curing stage when the parts are still semi-solid by blocking them and exposing them to more UV light.

You might get some “serendipitous” results using heat and pressure (bending and blocking), but what’s most likely the case is that the parts are still not fully cured at the time.

FDM printers (“string” printers) do use thermoformed plastics and heat to make the 3D parts, so their response to heat is entirely different.

Warpage and other deformities in resin 3D printed parts should be unacceptable on the consumer end. 3D kit makers should complete their post-print processing to ensure the parts and kits they sell and ship are defect free.

Exactly why this is not currently on my “to buy” list. I don’t mind fixing mistakes (I built lots of AEF Designs stuff before I knew any better) but we’re pretty far along into the 21st century.

Well, I’m due to get this one tomorrow; I will subject all to scrutiny but also assess what is fixable, which by the sound of it, it may well need, and how to tackle it. I might have my work cut out (no pun intended) as I’m pushed to cut a straight line in plastic card.

Thanks to Bill for the heads up; I just couldn’t resist this one!

Indeed! I suspect that the M59 released in injection molded plastic is not too far off, anyways, so I’m also willing to wait.

However, I just don’t have a lot of sympathy for 3D after-market and kit makers. I understand why they rush their products from the printer to the package because it takes time and effort to properly complete the post-printing process. But just because I understand it doesn’t mean I accept it.

Packaging up parts that are still not fully cured is a recipe for just what we see here in some of these reviews. The parts are deformed when they’re removed from the printing supports and packaged so that they’re bent and curved by the packaging and other parts. They continue to cure, finally taking set in the deformed condition.

This is analogous to injection molded kit makers pulling the sprues from the molds and packaging them up while they’re still so hot they haven’t fully hardened. You wouldn’t accept a box of deformed plastic sprues from any kit maker, especially after paying as much as many of these 3D printed kits are going for.

None of this should be acceptable to the customer.

It may not be too far off (in injected that is) Michael, but some of us are running out of time!

I think you are being ridiculously harsh.

Hobby Link’s kits fit well, but because 3D printing is more rigid than styrene, it’s harder to correct warping. I disagree with your assessment that the resin can’t be fixed. I have done it, with boiling water (10 seconds in). Hair dryers are also considered an option.

We have been putting up with warping in styrene kits for decades (the hull for the Dragon M1A1 Abrams is notorious for its fit issues). 3D resin printing is a newer form. But to expect a small manufacturer to wait until all possibility of warpage is past, or to replace everything that might go wrong is, in my world, asking so much these small shops will soon go out of business. I’d rather have the kits (which you aren’t going to buy anyway by your own statement), than wait for styrene manufacturers who may or may not come around.

Very nice. It came out great.