First, you should understand that “scanning” is not some sort of magic process that will save you time and effort over learning to do simple CAD. 3D scanning is not like scanning or copying a document and then just printing a copy of that. 3D scanning is a process that requires not only the hardware, but also the software and skills to use both. I’m sorry to say, but “scanning” is just no shortcut to creating 3D printable object files. Can such objects be created using 3D scanning? Yes. However, this is no path for the beginner to 3D printing.

If you want to get started in 3D printing to support your fine scale modeling, you are much, much better off starting with learning to do simple CAD and then converting those CAD into 3D printable stereolithographic files (.stl files).

I highly recommend that you start your self-study efforts with TinkerCad and, if you find that you’re still enthused enough to get deeper into CAD, you move on to Fusion360.

Here’s the link to TinkerCad:

TinkerCad

Here’s the link to Fusion 360 - Personal Use Account:

Autodesk::Fusion 360:: Personal Use Account

Both software packages are products of Autodesk and learning TinkerCad will help in understanding the fundamental way that Fusion 360 works. Both also have very good self-paced tutorials.

I do a lot of simple 3D design and printing to supplement my own modeling. From small models, to parts, to fixtures, forms and other one-off tools and aids. I use my 3D printer a lot. The essential skill that you need to acquire and develop is how to design your own objects. The actual printing is simple. The skill and effort are in the design part of the process, and for learning this, TinkerCad followed by Fusion 360 is the most straightforward path that I know of for an absolute beginner.

Here are a few examples of some 3D models that I’ve designed using nothing but TinkerCad and printed on my desktop Anycubic Photon, MSLA printer:

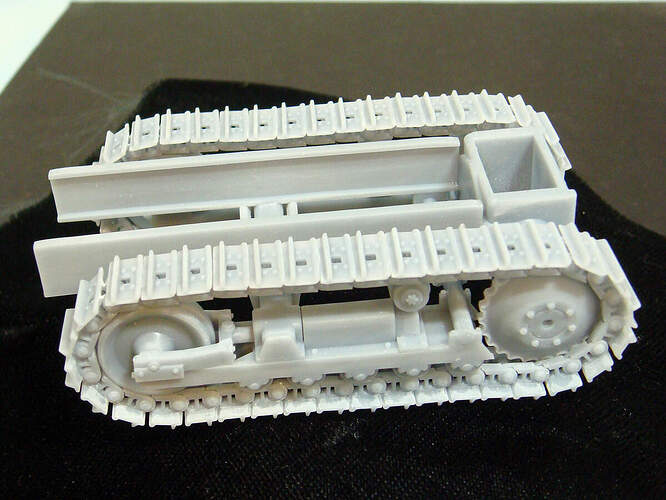

1/35 scale M450 dozer chassis and suspension (to include link-to-link tracks).

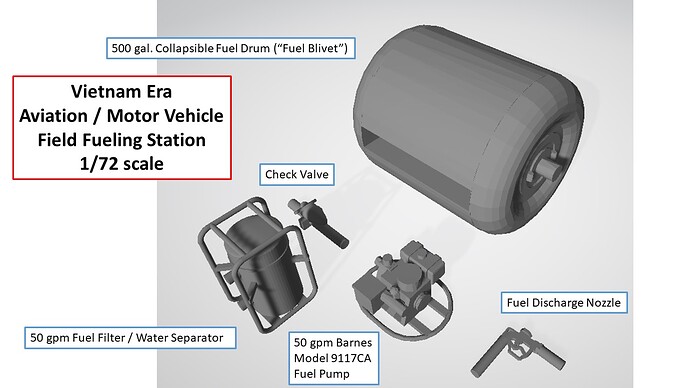

Renders of the components of a 1/72 scale Vietnam era field refueling station.

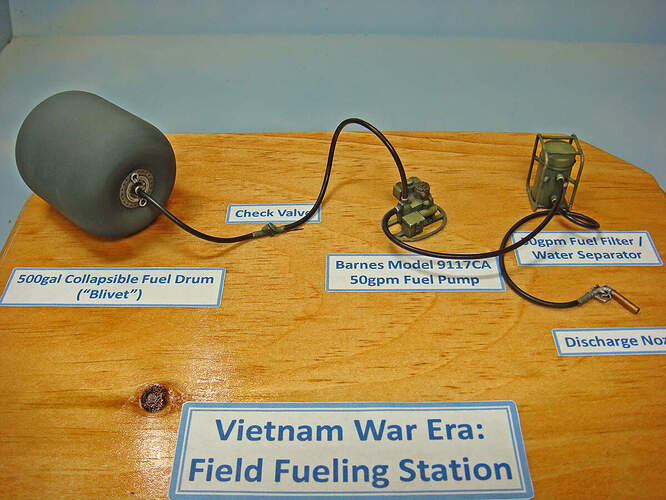

The same designs rescaled to 1/35, printed and painted.

1/35 scale AN/PRD-1 Vietnam era portable radio direction finder unit.

I could keep posting up more. Again, all of these designs were done using TinkerCad which only takes about an hour or so to complete the tutorial for. After that, there are quite literally dozens of YouTube videos that have been posted up showing how to use TC to create different objects that might seem to defy its capabilities. Once you’ve mastered TC, the transition to Fusion 360 can take your design work to a whole higher level.

There are many other options and excellent CAD software packages out there, and for someone determined to learn a CAD program or who already has some background and knowledge in computer aided graphic design, one of these other CAD programs might be a better choice. But if you’re going to learn on your own… TC and F360 are the way I’d recommend.

. I’ll happily share anything learned if I go down the 3D path. Definitely agree, its a part of modeling’s future.

. I’ll happily share anything learned if I go down the 3D path. Definitely agree, its a part of modeling’s future. for a Barbie doll. Hope to talk with him this weekend.

for a Barbie doll. Hope to talk with him this weekend.