Dear Friends, long before I joined this august body to render my pointless views on all things armor modeling, I was watching that other platform YT and learning how the so called “pro’s” build their German WWII armor models so I could learn the hobby. After ordering various quality kits from reputed manufacturers I was struck by how detailed some of the basic model pieces were out of the box. No flash. Rolled steel texture, you name it, the good ones have it.

But then an incongruity struck me after delving into how the Wehrmacht built their armor (for most of the war). Ironically, the same reason accounted for why they lost: they kept to their craftsman static building process while the Allies emulated, or at least tried to, the Henry Ford mass production model, which by WWII included automated welding, Ironically, in some cases, outcomes on welds came up wanting. Meanwhile, in the Ruhr Valley and elsewhere, the Germans,(ultimately to their own ruination) had skilled welders making seemingly perfect welds. Sometimes one AFV would have a team of welders doing different seams, without the automation used by the Allies. I’ll not delve into the techniques thereof as I know little of them, but, the fact remains, that after the Soviets captured Panzers they marveled at the uniformity and aesthetics of German welds. See https://en.topwar.ru/169350-svarka-tankovoj-broni-nemeckij-opyt.html.

The whole point of this is: why do so many good modelers almost automatically get the chisels and blades out and eradicate the model welds and replace them with epoxy sausages ? My further point is why do it when the welds are detailed and to scale? Now, to each his/her own, but to many, this process is de rigueur. Why? I’m asking not having an answer. I can understand if the kit piece has crappy welds which require enhancement, but I don’t automatically erase anything unless the model lacks something, do you.? I’m trying to figure this out. I could also make the same argument about so called “armor texturing”, but, that’s another subject. So, please help me out here. Often times some of the replacement seams and beads seem out of scale to me, or have some of the flaws Soviet welding sometimes did. I’m not trying to be a provocateur here, but this seems so nonchalant it struck me as odd. If it ain’t broke, don’t fix it. You can always enhance kit welds by weathering them with a glint of a chipped weld bead or something, no? Id like to hear from you pros out there your philosophy. Thanks.

Dan

Some people prefer the clean lines of a tank without those pesky welds in them.

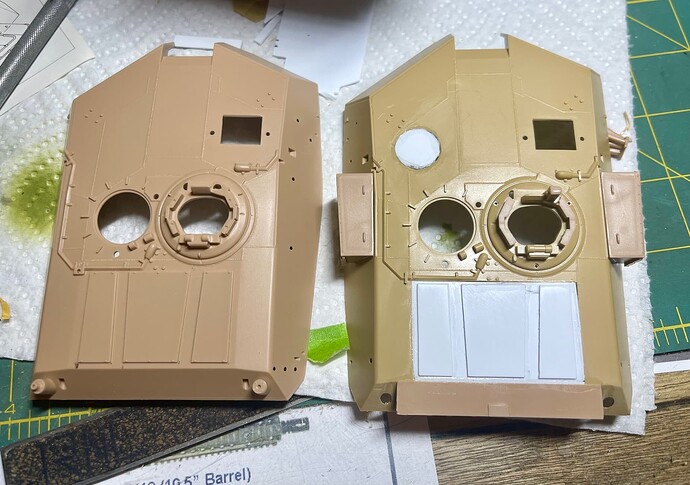

I wwent slightly out of my way to repair the weld seams I obliterated while modifying the turret roof on the M1A1 Abrams turret I used to backdate it into an M1IP turret for my Tamiya M1IP build.

I had to mod the upper turret off the Tamiya M1A1 in order to replicate the “Long Turret” mod on the M1IP; including plugging up the location where the CITV would eventually end up on the M1A2.

After plugging up the hole and replicating the three blast panels on the M1 turret, i had to somehow add the weld seam on the turret where i plugged up everything.

I kind of did it by taping off the line where the weld bead would typically be, then applied some Mr. Finishing Surfacer 500 to apply in small layer so it would build up just enough, so that when i removed the tape, it would not lift with it.

I think it came out well for what it is. I know that Archer Fine Transfers did a resin decal that replicated weld beads; another option is to make the bead using Green Stuff putty, specially if you want those weld beads to stand out, since some models kit the weld beads are not pronounced enough that they disappear one the primer, paint and washes start piling up.

Or…

SableLiger:

You’ve demonstrated that you had very good reason for doing welds. I think some people do it just because they think they have to or it looks better. Just an observation, but your detailed post shows me there’s some thought being put into this. Thanks

Dan

Maybe it is a “fashion”, similar to making a half year old vehicle look as if it has been exposed to weather, constant use and war for a decade.

Maybe. Problem is that I don’t recall any YTber ever mentioning that. But, your thesis is a perfectly valid argument

I bought a book about model ship building 40 years ago.

In the chapter about details and scale the author recommended

that details that would be hard to see in the chosen scale should

not be added since they would probably be out-of-scale.

Adding exaggerated details simply because they can be seen on

the real thing from armlengths distance might not be wise,

especially since viewing the model from 30 cm distance could

be equivalent to viewing the real thing from 35 meters distance.

Lots of details disappear at that distance.

Model ships, both 1/700, and 1/350, just don’t look right without deck railings.

![]()

![]()

When you study reference photos, you will see that lots of models have missing weld beads that need to be applied. Depending on the scale, stretched sprue, or very fine styrene rod (Evergreen) makes excellent welds.

![]()

![]()

I’ve thought this very thing. Why would I want to obliterate correctly scaled kit weld seams for wildly exaggerated epoxy putty seams? It just makes no sense to me.

Add to that the fashion of adding deep dings and divots to “simulate” rolled steel. Sure, make the Panther look like your wife parked her minivan on the golf driving range for a weekend…

Yep, and the end war / Panzer ‘46 models that look like they were in continuous combat until 1973. My Panther F kit — I intend to portray it as what it might have looked like on its second and last day of combat. So, no “chipping” and heavy weathering like it was just pulled out of a boggy marsh in Estonia.

Which brings me to fuel stains: how likely is it that crews were just haphazardly dumping fuel all over a deck?

[quote=“M70, post:9, topic:39250”]

dumping fuel all over a deck?

[/quote] is a bit of an exaggeration. Oil and fuel will always be spilled, especially when poured from a Jerry can, etc. eg; How many times have you spilled even a little bit of windshield wash when refilling the reservoir?

![]()

![]()

Why, never… ![]()

Riiiiight! ![]()

![]()

![]()

as usual Uncle Heavy has hit the nail on the head!

M70: brilliant. i wholeheartedly agree

Some modelers wish to create more realistic and accurate weld beads on a model that has simplified them or in some cases left them off entirely. I recall that some manufacturers weld beads on the Sherman hulls are slightly below the surface when they should be above ( or even with ??) the surface of the plates that join them. I think Tamiya is one of them. That never bothered me, I don’t recall ever having done that myself, on a Sherman, I usually leave them as they are. I did add a weld bead ( rather clumsily) to the commanders cupola on an Egyptian SD-100 a few years ago. I should have done a better job but I just left it .

I think you and @M70 have very valid points here. At times way overdone and out of scale. Just because you CAN do something doesn’t mean you SHOULD. This hobby is regularly struck by fads and most of them are not good.

I have to say I decide on a case-by-case basis. If the moulded ones are good then I leave them and save the effort for other details. But if they are missing when they are obvious on the real thing I add them. And if they are visibly wrong (like all those Sherman hulls with trenches where upstanding welds should be) I do the necessary surgery. I put a lot of effort into my models and don’t want to have bad details staring back at me every time I look at them…

Dear Metalhead85:

I agree with you and I think your point is rational. That is, a modeler sees a weakness in the kit piece and goes to work improving it. hell, I do that.

My question was more like why do some modelers seem to do it all of the time with no expressed reason? That’s the rub.

I wouldn’t stand for crappy weld seams either and I’ve had to go to work on some, but rarely. And even than, mostly it’s a to scale Evergreen styrene rod which I cement on with Tamiya Extra Thin cement, the use a hot knife to easily lay in seams.

I try to stay away from two part epoxies as I’m tired or the rolled “sausages”:sticking to everything but the weld seam (and yes I have water on everything to prevent this but it’s hit or miss).

So, I think your point is well taken and denotes a case in which doing homemade weld seams is a must. Thanks

Dan

We aren’t. Let’s make that distinction right away. Some modelers overdo it, some leave it alone, and some do very convincing work. I myself do what pleases me - and that it is to replicate what I think needs to be replicated. A case in point - the venerable T-34. Some welders did a better job than others, but you can’t discount the fact that there were some ugly welds being made. Also don’t forget they weren’t TIG welding these tanks, it was stick welding, which has an inherent thickness no matter how good you are.

The fender welds aren’t even represented on the Dragon kit.

I also like to do my own research - this is from the T-34 at the War Memorial of Korea.

I guarantee they’re visible from a good distance away, so I modeled them. Same location as above photo:

Aft portion of fender:

They get as fine as you want them to get - there are CA spread with the point of a needle:

I imagine most folks know how small a tank periscope is. These are some pretty tiny welds on this scratchbuilt armored car turret:

And if welds are ugly in real life, I make them ugly on my models.

The uglier the better - from an SU-100 at the same museum:

They were correct. I’ve seen several instances where butt welds appeared to be sunken. This from a Sherman at the same museum:

I could go on all day, but I’ve got things to do.