This is the 2016 ‘2in1’ Bronco kit #CB35214. It was the last release of a series of sWS variants, that were based on the original Great Wall Hobby mouldings stretching back to 2009.

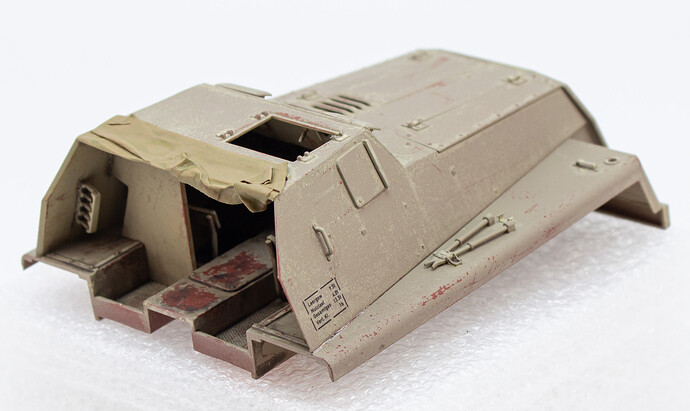

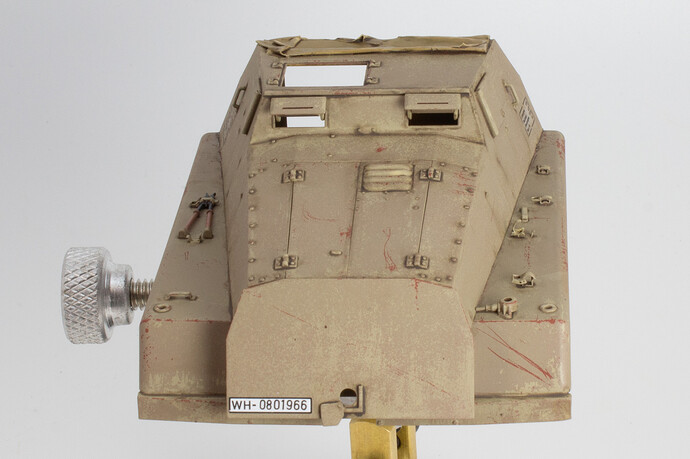

The detail is sharp, and the armoured cab thickness is nicely rendered to scale. Although there is a small degree of mould offset on a few parts there is no flash and very few pin marks present. It is also nice to see well thought out sprue gate connections, making removal of the access easier to accomplish cleanly.

This kit gives you options to build a supply ammo or armoured cargo version. I decided to build the produced armoured cargo version and used the Nuts & Bolts 41: Bussings schwerer Wehrmachtschlepper (sWS) and Variants as a reference guide. The book has a nice feature clearly showing all the design changes from prototype to production series by way of colour coding CAD scale images.

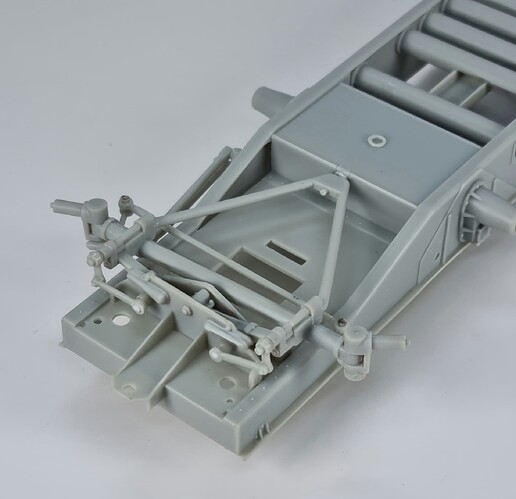

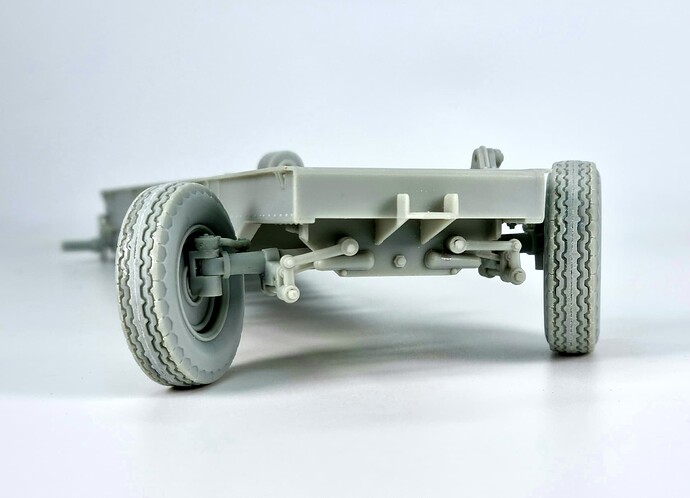

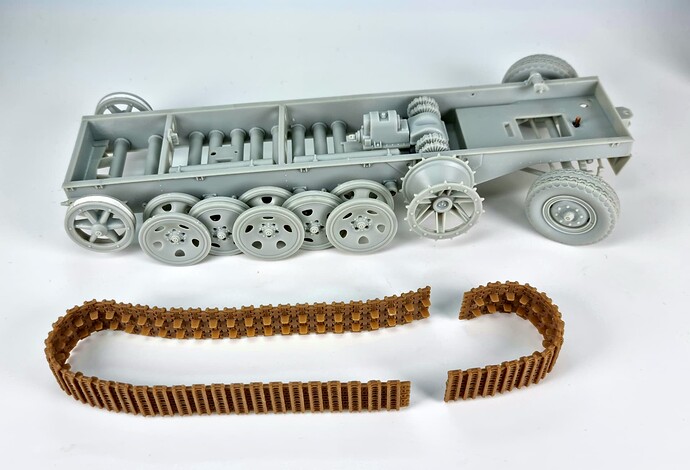

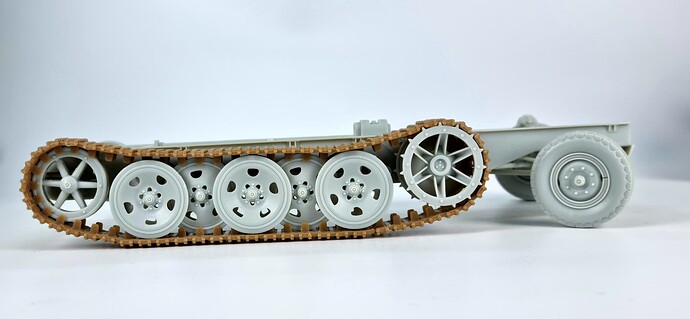

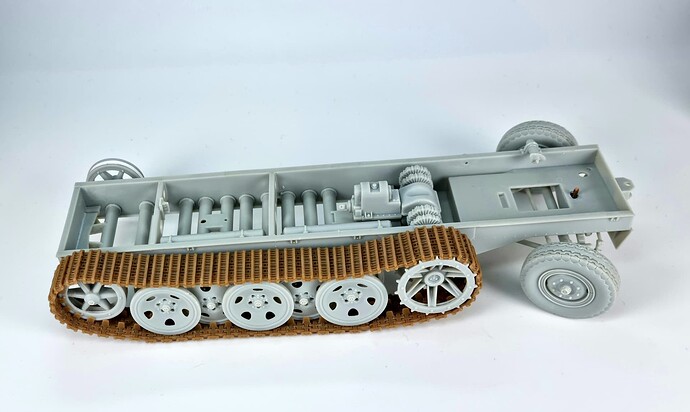

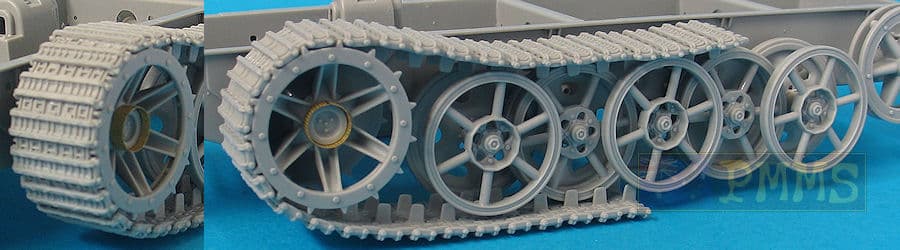

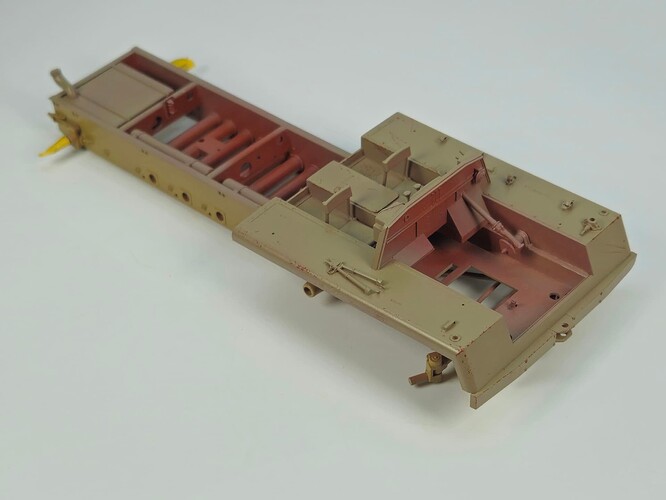

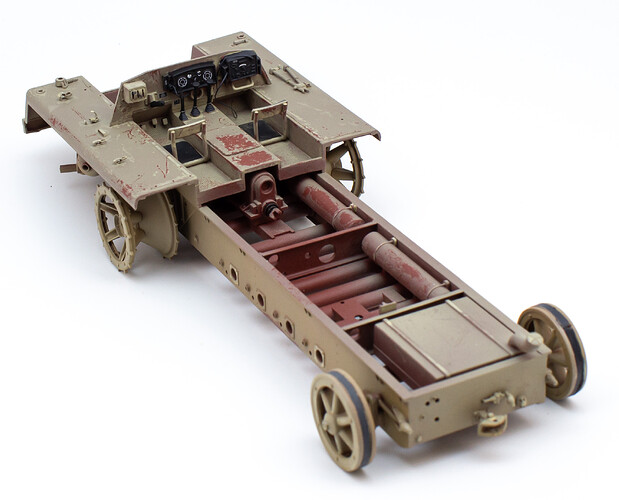

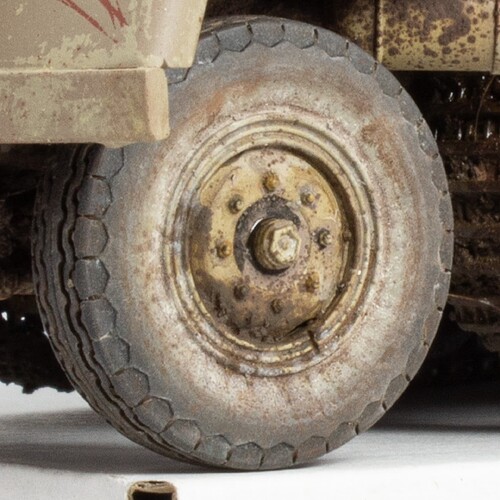

Steps 1 through 6 concern the construction of the chassis and suspension. It all fits neatly together although you do need to ensure the multipart torsion bar tubes are fitted in the correct places. I would also recommend leaving the idler axles off the chassis if an aftermarket set of tracks are used. I am up for the challenge of making the kit’s individual link non workable ones look good.

Steps 7 through 9 have you adding on the chassis inner bracing panels, the fuel tank and winch accessories. Only one in four production SWS’s ever received a winch so if not fitted the holes in the rear panel remained. I’m not fitting mine.

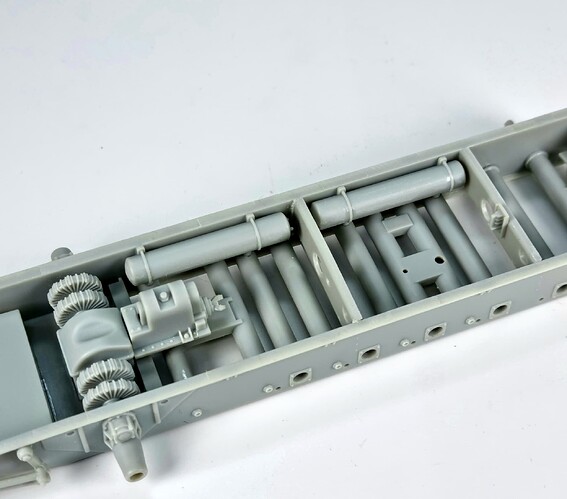

Steps 10 & 11 build up the *Maybach HL42 TRKMS engine. The engine looks highly detailed, but I won’t be fitting this to my kit, so I can’t comment on its sutability or fit.

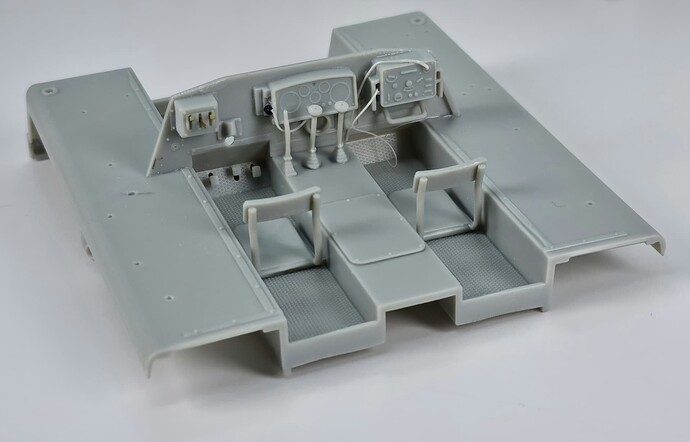

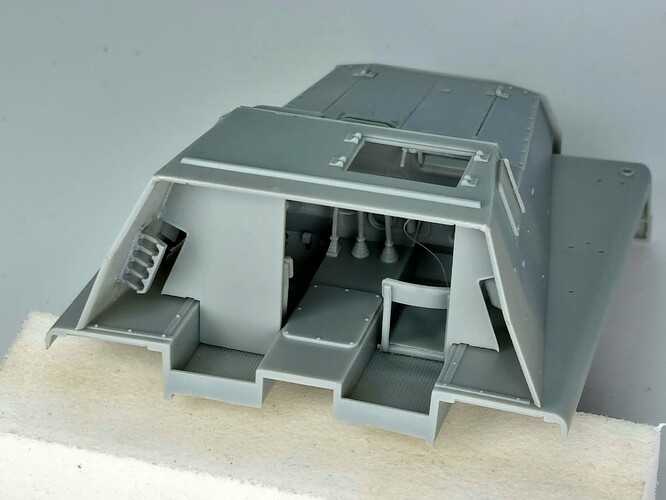

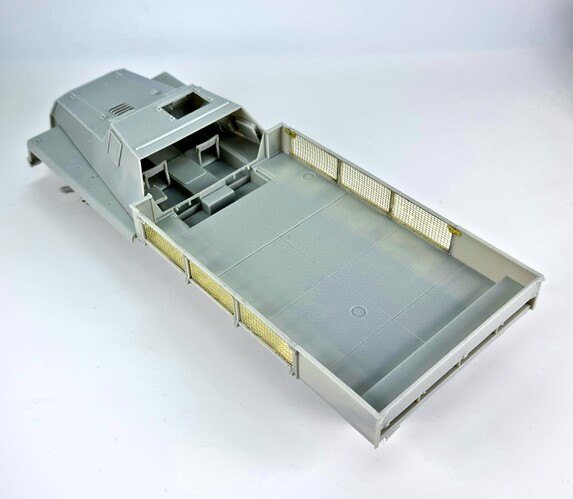

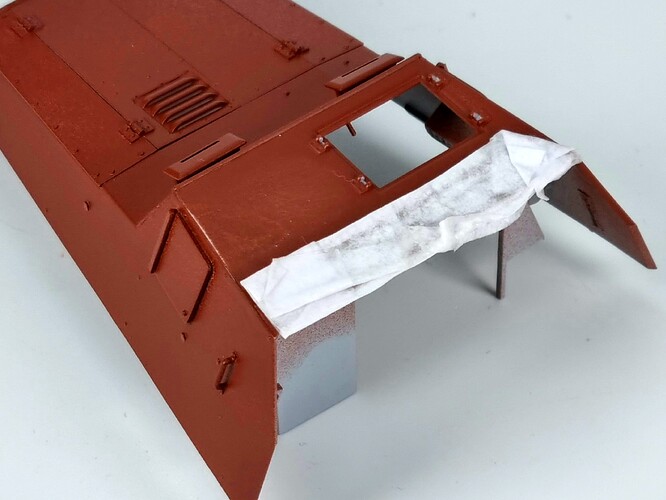

Steps 12 to 20 have you build up the upper armour components, adding tools and all the interior parts. You are also given alternative photoetch clasps to complete all the pioneer tools although you will have to shave the plastic clasps off the tools first.

Step 21 to 27 concentrates only on option 1: the enclosed armoured supply ammo version and supplies all the nebelwerfer rockets that this version would likely have carried. As I am not making this one let us skip right on to step 28.

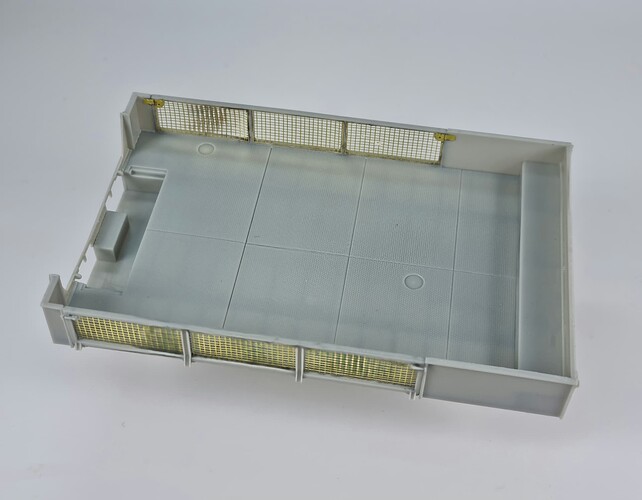

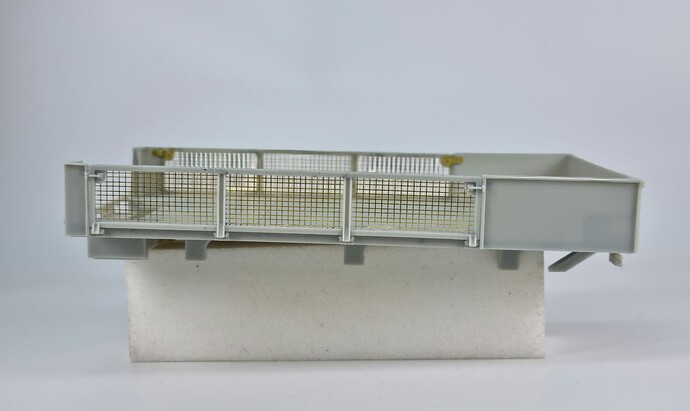

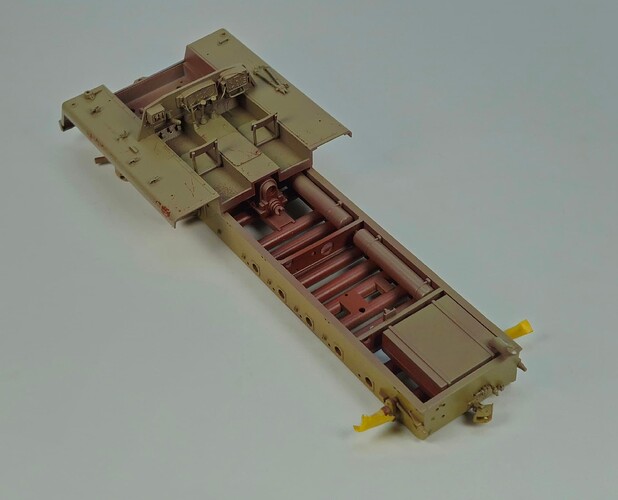

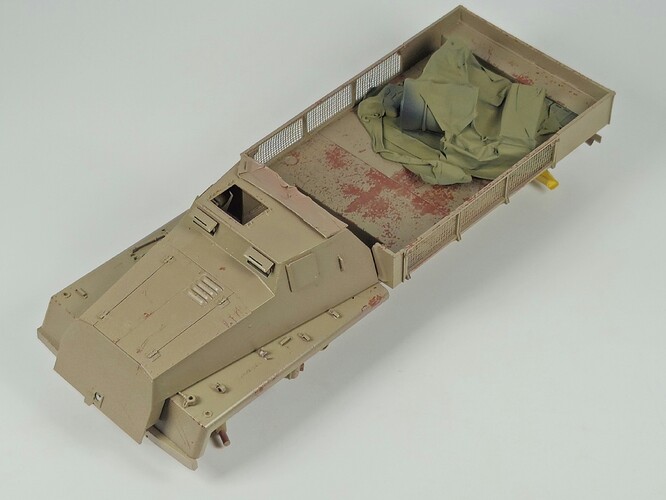

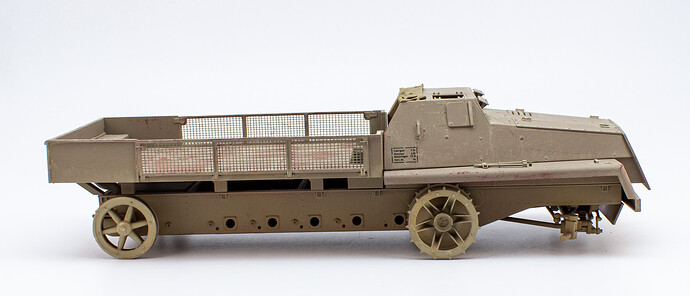

Steps 28 through 34 is just for the armoured cargo version and builds up the rear cargo platform. The front two thirds of the cargo sides are hanging and are represented by a plastic frame and a photoetched inner grill. No fitment issues at all here and although the latches are moulded in, it all looks good when built up.

The platform bed floor is a tricky one. Other than a couple of ref images I cannot find any showing the armoured cargo version from above, so it is difficult to know what fixings were attached, if any at all? One of the images seems to show some ‘L’ shaped brackets over on the driver’s side but what they were for I’m not sure. There are circular location marks for the Flak 43 carriage on the kit’s platform and there are a few parts like the risers and fixing cross bar for that gun still on the sprues. If the vehicle was solely used for cargo, it makes no sense having the tubular flak carriage risers protruding out of the floor to limit floor space and for crew members to trip over etc. The N & B CAD images of the production cargo vehicle have no fixings evident, so I think it is safe to assume they were not present on the cargo variant platforms. I guess the flak platform fixings could always be retro fitted anyway.

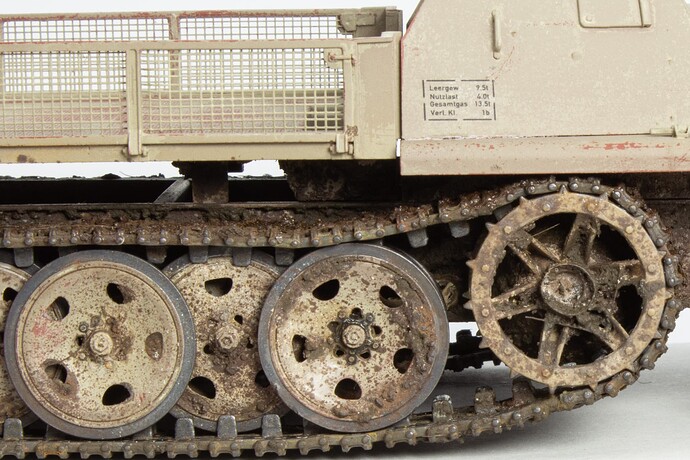

The instructions state to use 112 track links per side yet the N&B book states that only 110 were used. Without any idler adjustment its going to be whatever it turns out to be I guess!

Not the easiest design to manipulate so they have been broken down into seperate runs

There are two sprue gates per link and a pin mark on every pin link. So, by my reckoning that’s at least a minimum of two hundred and seventy-five individual clean up steps EACH SIDE!

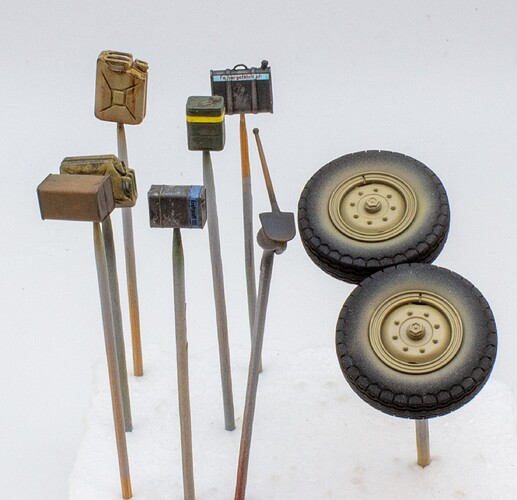

Jerry cans and oil drums were added to the Bronco kits, and they are a nice addition. You get individual water and fuel marked Jerry cans with PE reinforcing strips. You also get moulded together rows of Jerry cans which saves building individual ones and then hiding half of the detail. A selection of oil drums types are included along with their syphoning tools.

PAINT SCHEMES AND MARKINGS

The kit offers up just two paint schemes for the ammo supply vehicle and neither state any divisional info. One is in plain Dunkelgelb and one in a tri-tonal camo. As for decals just a weight stencil and number plates are provided.