Thanks H.P. that´s what I looked for!

Hi guys,

Perhaps Gilles Peiffer from Blast Models is interested in casting these Stinger cases.

Last time I ordered from him I asked if he had any intention of casting the AC-unit for the M 1128 Stryker MGS.

If he is willing then shipping costs is muck cheaper then ordering from The States.

I hope he’s reading this forum !

Gé

I just contacted another resin company in Europe. Will tell you if he is willing to make and cast the boxes.

Thank you, Sir !!

Gé

I believe the explanation for the price increase you see is VAT (Value Added Tax).

When you login and Shapeways understands that you are a “lucky” EU citizen, they add VAT to the base price.

This is how it goes in EU -

I think the Verlinden cases may be too long. I have one, but I haven’t measured it yet. It is too long to fit where they should in the back of an M6 Linebacker Bradley, which is what I intend to use them on. I will measure it later and let you guys know.

Gino,

a reliable source state that the case is 62inch by 12inch by 13inch. Which means 45mm long, 8,7mm wide and 9,4mm high.

Good info. I’ll measure them when I get home later today and let you guys know.

It’s actually 47.89 (47.9) mm. But I’m not going to go out and buy another battery for my micrometer just for this.  I think I can kind of eyeball “slightly less than 48” mm.

I think I can kind of eyeball “slightly less than 48” mm.

Even though I said I wouldn’t, I started fiddling with this a little last night. I already have the basic shape, but then I saw another shiny object out of the corner of my eye. If someone else is going to cast these that would be great.

As I suspected, the Verlinden storage cases are too long. They are 49.9mm, by 8.3mm, by 9.5mm.

For most applications the 2mm difference is not that critical. I could maybe see it only if you’re trying to fit them in the Linebacker, but even then I’d look at interior wall thickness of other things that could be altered first. Failing that, I’d simply take 1mm off of each end of the box. the would slightly alter the relationship between the end of the box and the reinforcing ribs on top. Sooo… I’d turn the box on its top, sand the ribs of, and then add them back in their new position with half round. Then add new lifting handles on the ends. A quick, easy solution.

Or as I said earlier, scratch one similar to the one I posted above. You’ve got a “blank” that’s close enough in dimension to be an excellent start. Height and width are fine, especially after painting. I’d sand it clean, cut the ends off, reround them, and add detail.

Can you post good close ups of the Verlinden part?

Yup, I had planned to cut back the one end that goes inside the Linebacker and can’t be seen well, then add handle and other details back to it to make them fit.

They go on the platform on the right side of the crew compartment (red outline) and the far end is pretty hard to see, so easy to hide any lesser details.

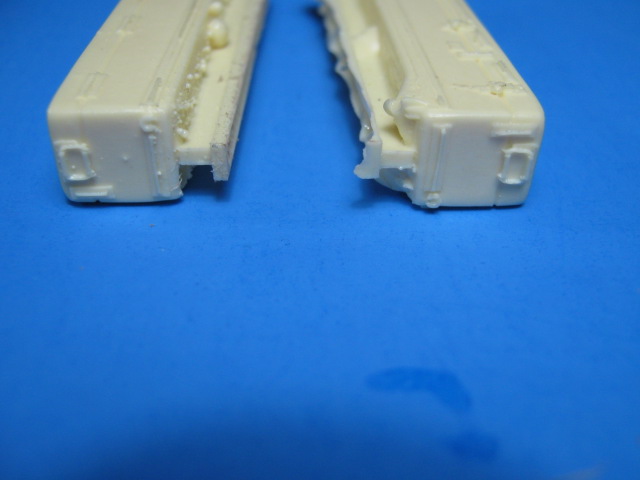

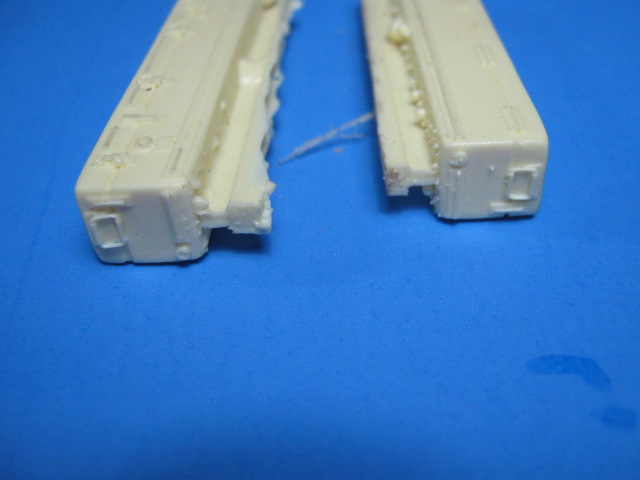

Here are copies of the Verlinden cases. They are not as crisp as Verlinden originals, but give you an idea how they look.

Voof. Whoever did that for you needs to invest in a pressure pot. So I presume you no longer need me to scratch one up? Hell, I’d just chop the forward end off and be done with it!

I would still like yours, which will look much better, if you are up to doing them. I still need at least 6, so…

I dunno about the troops in that Linebacker, Gino, they look kinda young and their uniforms must be some weird SOF civilian things…

I think I agree with the ‘cut one end off’ folks; very little of that case is visible under there.

Seems the new recruits are getting younger and younger these days.

Easier to fit inside smaller vehicles.

Ken

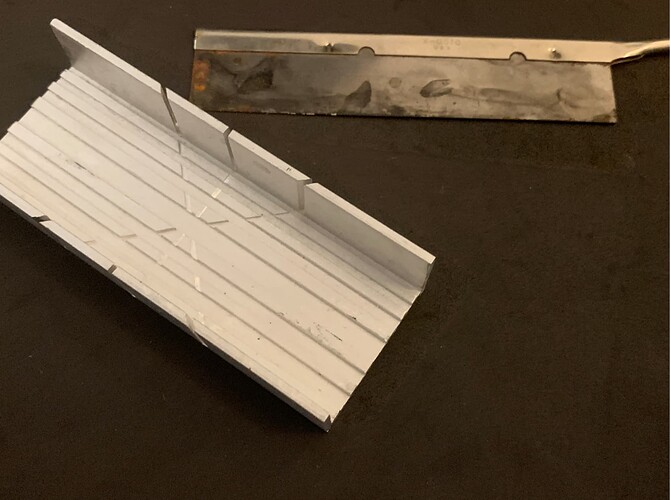

Sorry not to answer sooner or respond to your PM, but I’ve been on the road. Bottom line is that I’d have to do far more than six to make it worth my time. Driving to and from Hobby Lobby, making the master, the mold… Not to mention Hobby Lobby no longer has the perpetual 40% off coupon. Even if I paid myself $25 an hour for my time I’d be losing out. I really thing cutting the forward end off is the way to go. One other option I have not mentioned but that I have used in the past - make two cuts somewhere near the middle, then glue everything back together with CA. The kerfs should remove just the amount of material you need. The cuts will be invisible if you use one of these:

No problem. I may order the Shapeways one and modify it, then cast additional cases.

Re: the Shapeways case, I’ll be interested to see how you deal with the banding ridges and the fine details that you have to work around. In the end you may have to remove some of the details to get the major surface smooth and then scratch build the details after.