Thanks for all the great comments. I hope you guys are enjoying the series.

Next up is the “business end” of the unit, the howitzer section. Here I’ve depicted B-3 which was one of six howitzers in the battery. Unlike some later doctrine where a battery might have 8 guns and sometimes operate in two platoons of 4, we always operated as a single battery of 6. On occasion, a single “hot gun” might be deployed separately for a mission, but that was not usual. FA doctrine is different than Infantry and Armor units, where the Company CO “fights” the unit forward, and the XO is usually with the trains in the rear.

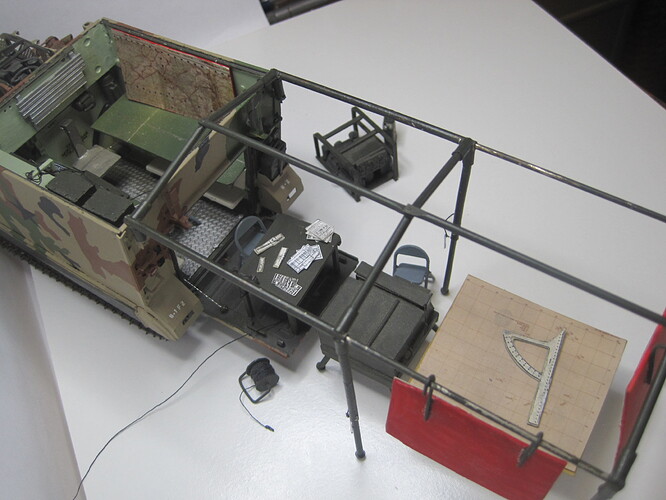

In FA practice, the XO is the “Firing Battery Commander” (like a platoon leader) and stays with the guns pretty much the whole time along with the AXO (assistant who runs the FDC). The howitzer sections, FDC and ammo section belong to the XO. His “platoon sergeant” is the “Chief of Firing Battery” universally known as the Chief of Smoke.

The Mess/Maint/Supply sections were part of the battery HQ and while the junior Forward observer wound up being the SLJO for all those on an admin basis in garrison, he was never in the battery area in the field, so the Battery Commander handled the “trains”, which for the most part stayed co-located with the guns.

During my time in the battery, there were two changes made. When I arrived we were still equipped with the M109 short tube, and all the vehicles were painted in solid OD. In June of 73 we were ordered to paint all our vehicles in MASSTER. A few months after that we were re-equipped with the long tube M109A1. I still have a picture somewhere of our gunline in the motor pool with half of the guns as short and half as long tube, all in MASSTER.

One of the most noticeable differences between the A1 and the A2 is where the panoramic telescope (pantel which is the “sight” the assistant gunner uses to properly aim the gun for direction) comes out from the top of the turret. The A2 introduced a closed housing which had a clear plate in the front which covered the pantel when it was mounted. The A1 still had a simple metal hatch which was raised to allow the sight to extend outside, but this allowed the sight to get wet and dirty in bad weather, so the A2 was a big improvement.

And finally, the 155mm uses “separate loading” ammunition, which means exactly how it sounds. The projectile is selected based on the mission requirements (High Explosive, Smoke, Illumination) and also fitted the desired fuze, either a contact or point detonating fuze, or a time fuze designed to cause the round to go off PRIOR to impact at some calculated time of flight designed to achieve a burst a desired height above the ground. Then comes the powder charge (which comes in a separate canister and has a number of “bags”, the more bags the greater the muzzle velocity and thus range). After the projectile was loaded, the correct number of bags of powder (or the charge) of powder were loaded “separately” and then after the primer (similar to a blank) was inserted into the breech and then the gun was fired.

The projectiles were kept outside of the gun on one side and the powder on the other, and it was the cannoneers’ job to listen to the fire commands and select and prepare the rounds per the orders.

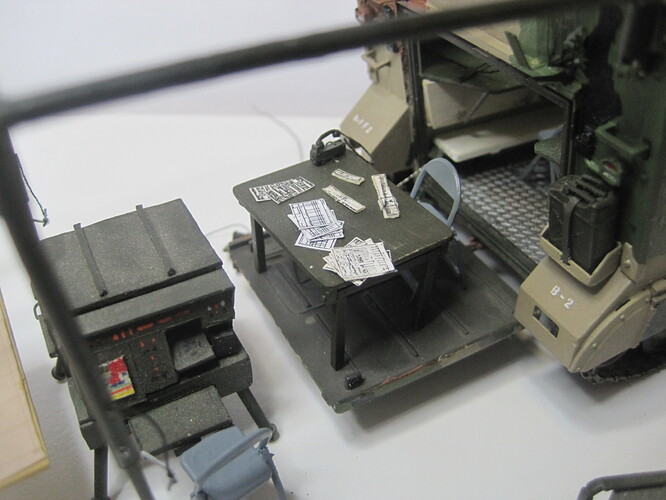

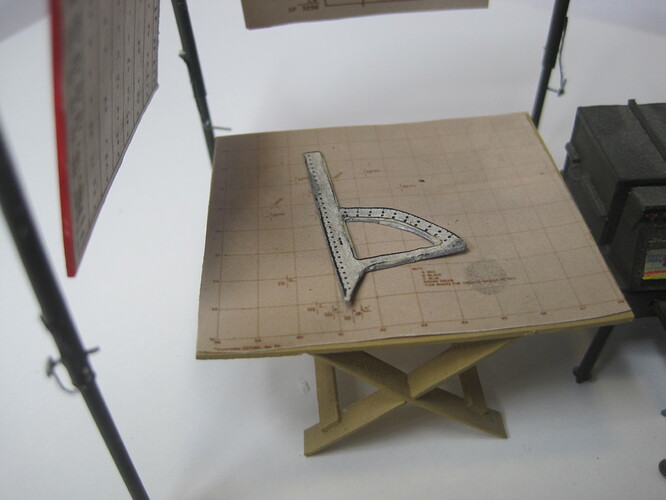

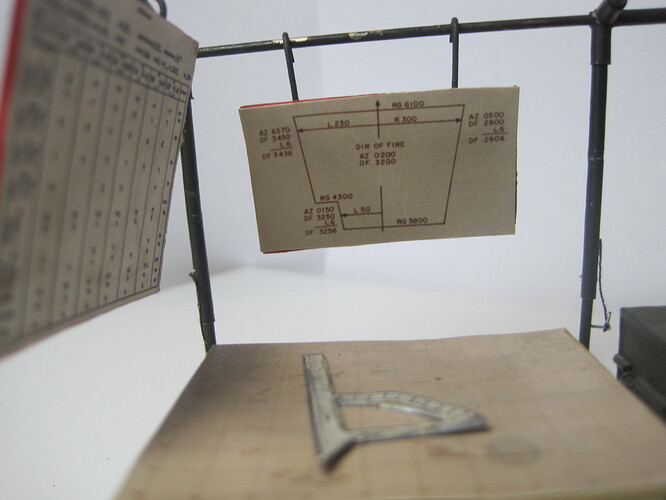

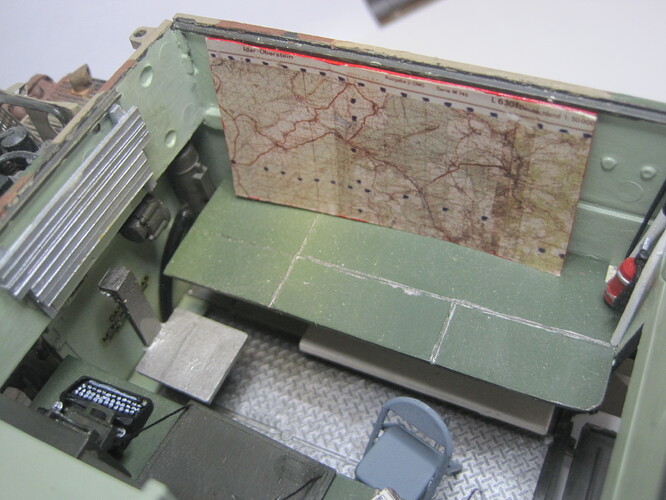

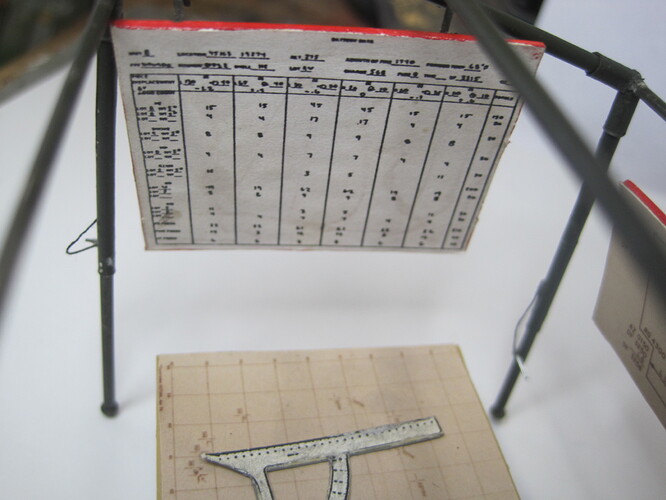

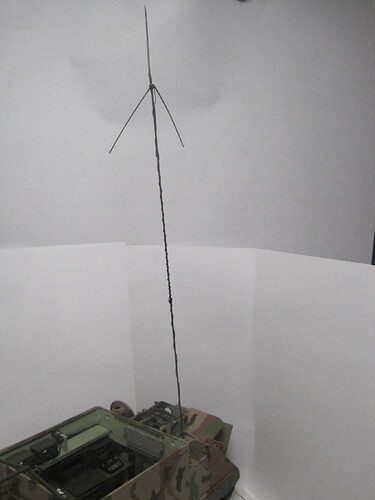

During this time the way the whole process worked was the FO calls the battery with the mission (voice on the radio), the FDC determines the ammunition to use and the firing data, and then notifies which guns are to fire, what ammo to use and how many rounds. The external communication between the FO and the FDC was by voice radio, and the internal communication between the FDC and the guns was done by sound powered field telephones on a wire network that was set up and taken down each time we moved.

Lots of moving parts!