If I’m at home; I’ll drop trou for more freedom. ![]()

Too funny! ![]()

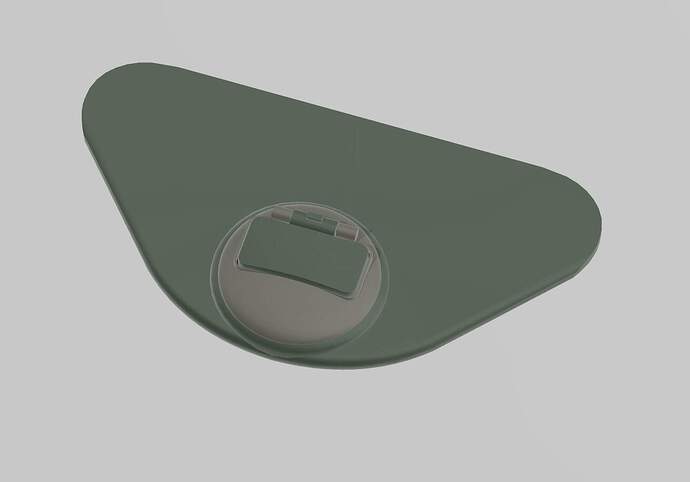

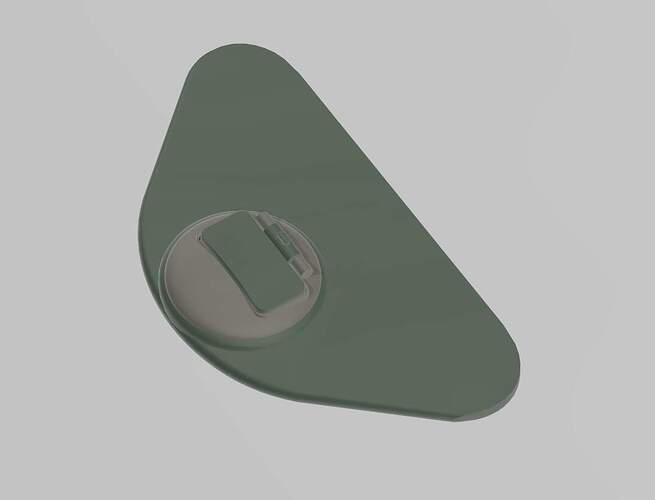

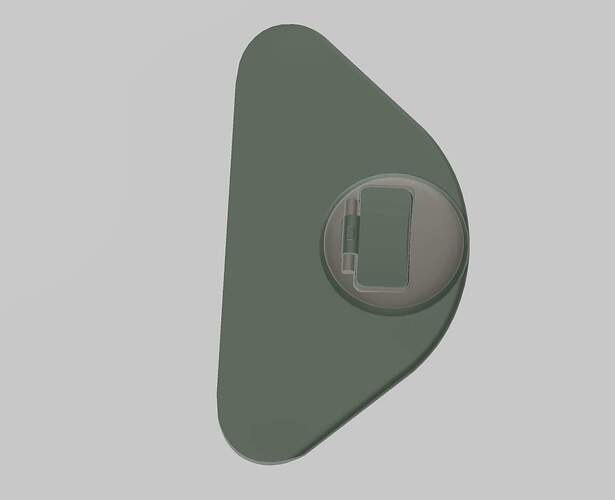

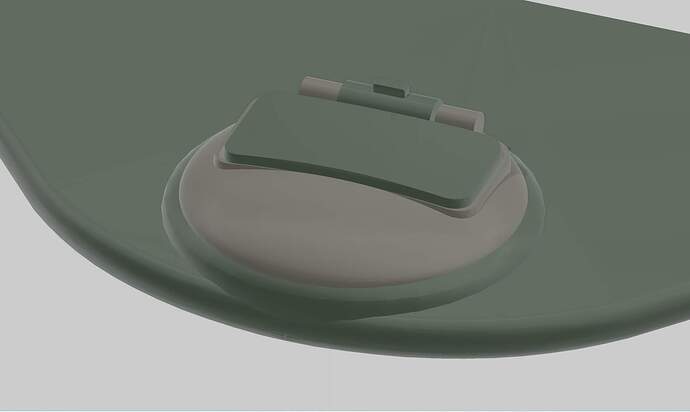

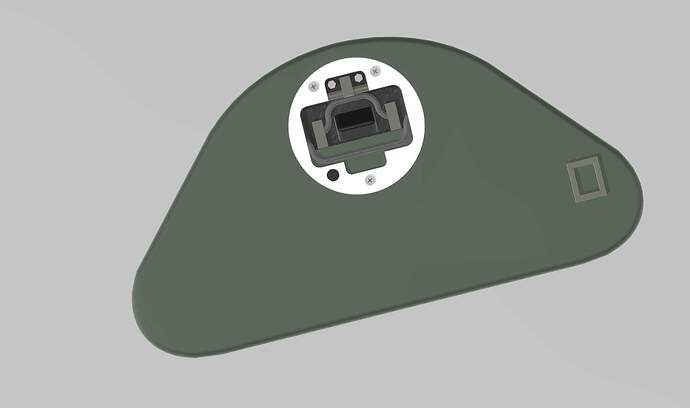

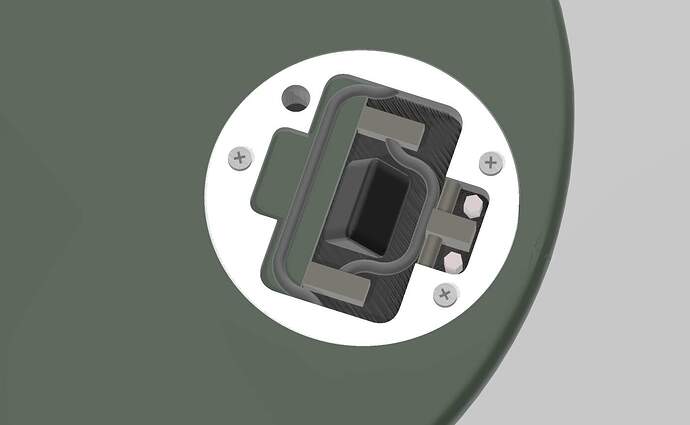

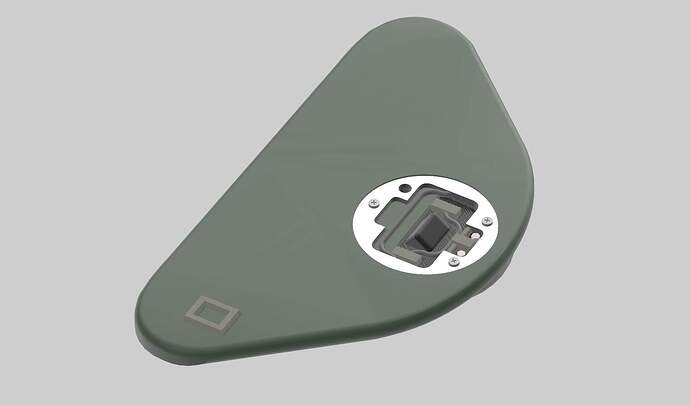

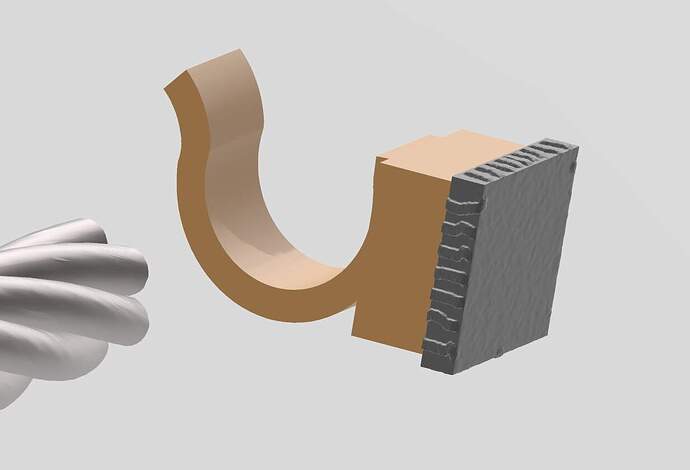

CADded for my M60 “Slick” project. 1/35 driver’s hatch for M60 or M60A1 to fit an Academy or Tamiya hull.

Spent too much time working on the underside, which will not even be seen once assembled…

Under side:

Reference photo:

Looks great!!

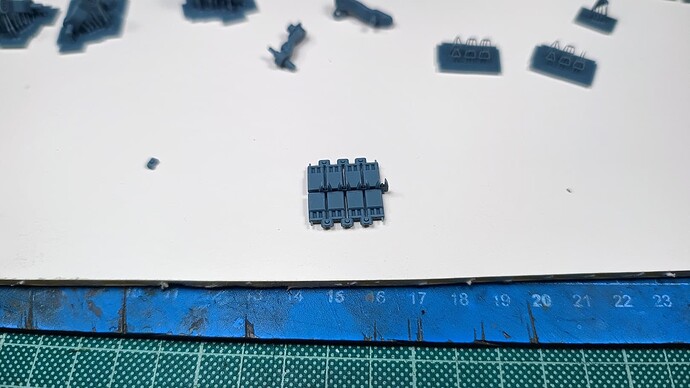

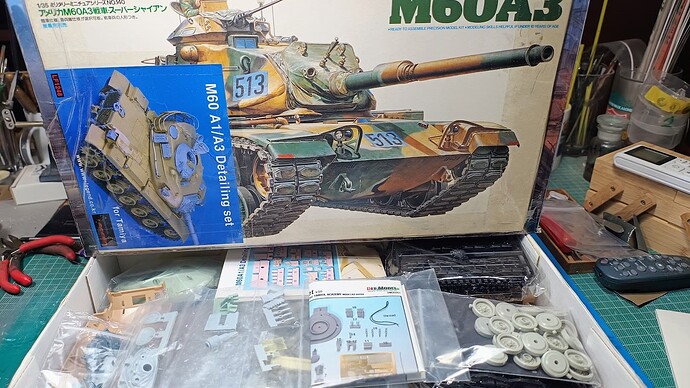

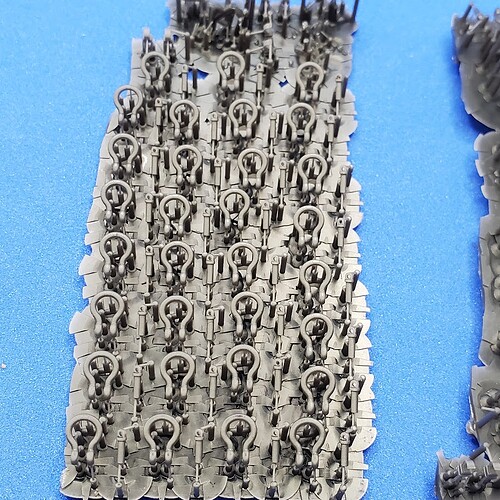

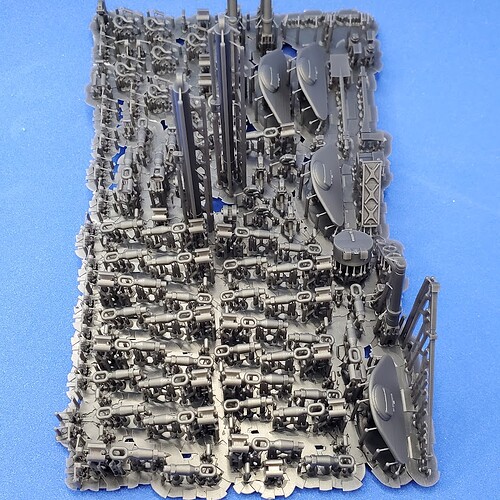

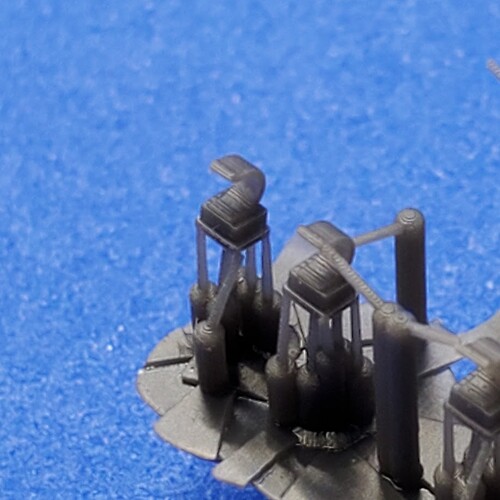

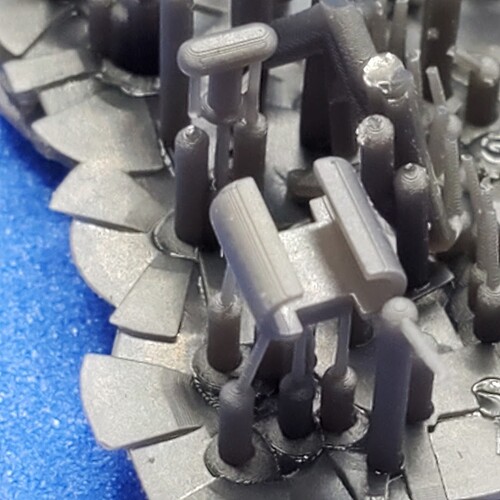

Bought the files and had prints done.

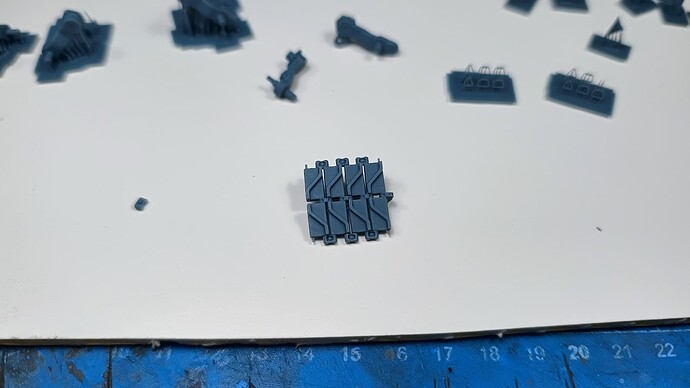

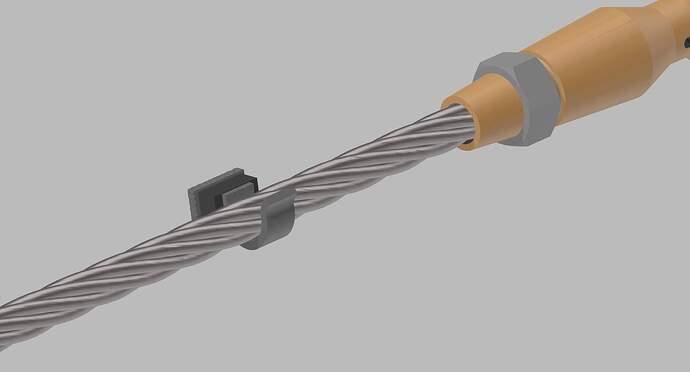

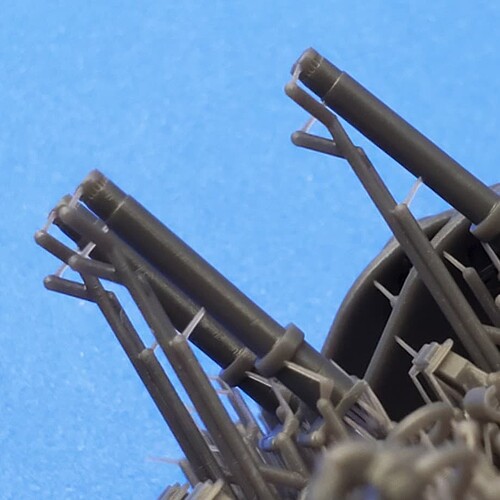

T96 track, excellent fit, will look great. The detail on the end connectors is top level

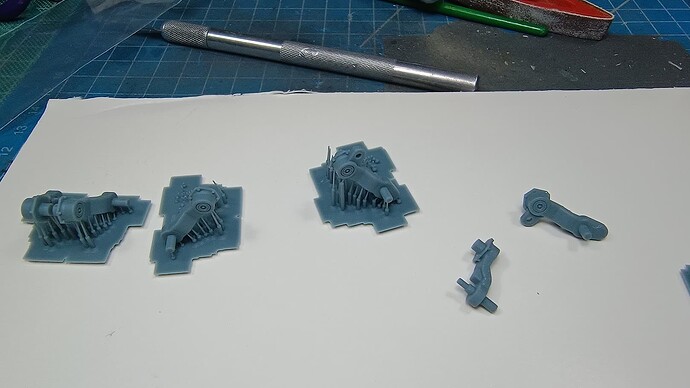

M60 suspension upgrade for the Academy/Esci/Italeri/Tamiya kits and upper hull handles:

Overall I am very impressed and will definitely print out more. ![]()

![]()

![]()

I will share the build using the prints after the holidays, once I sober up

Haha! Take it easy, Nikos! Thanks for sharing the photos and kind comments.

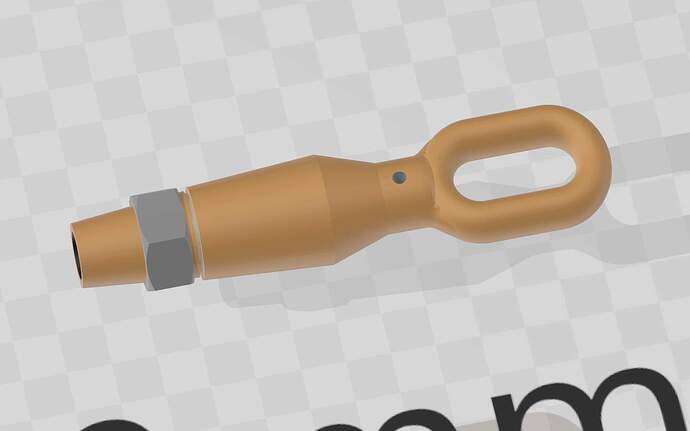

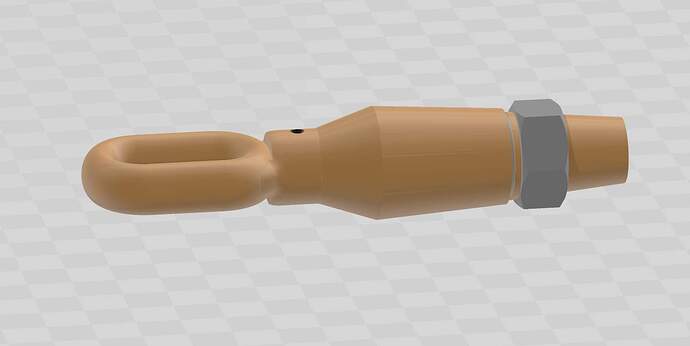

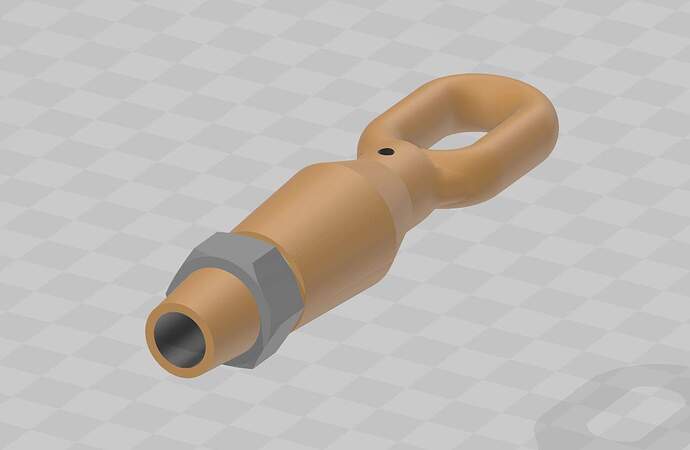

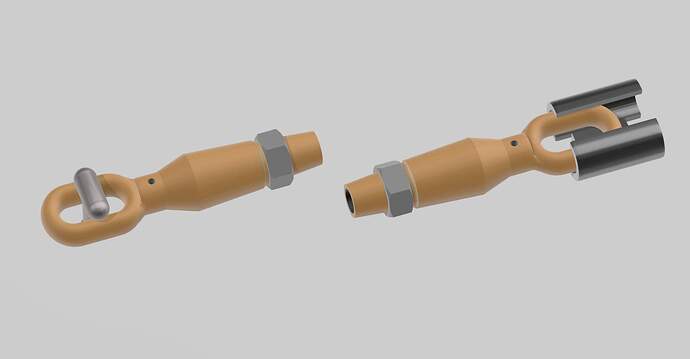

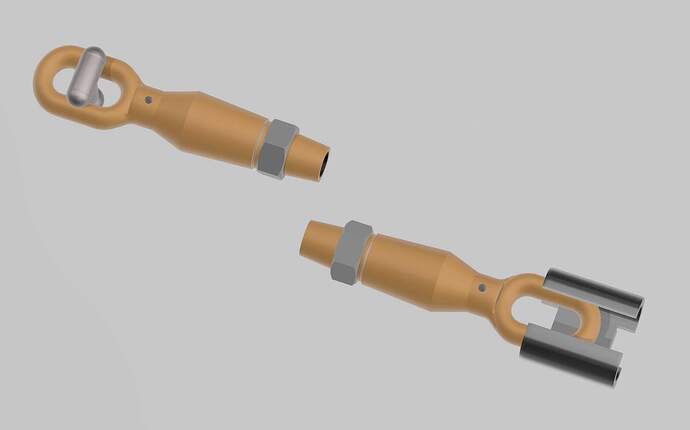

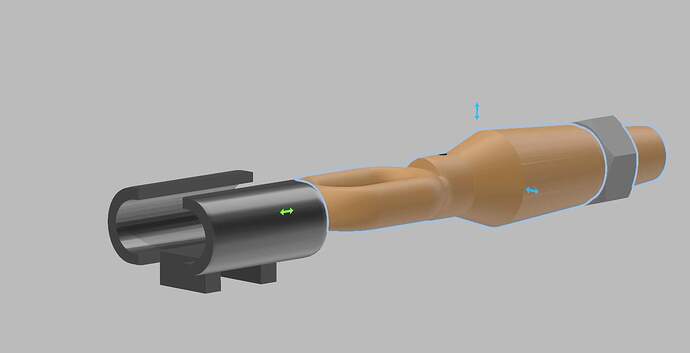

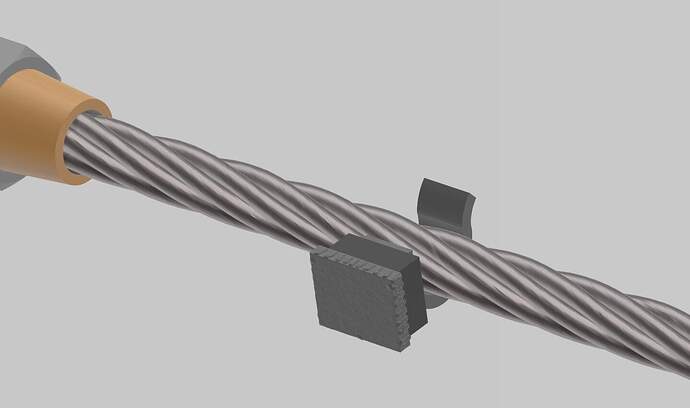

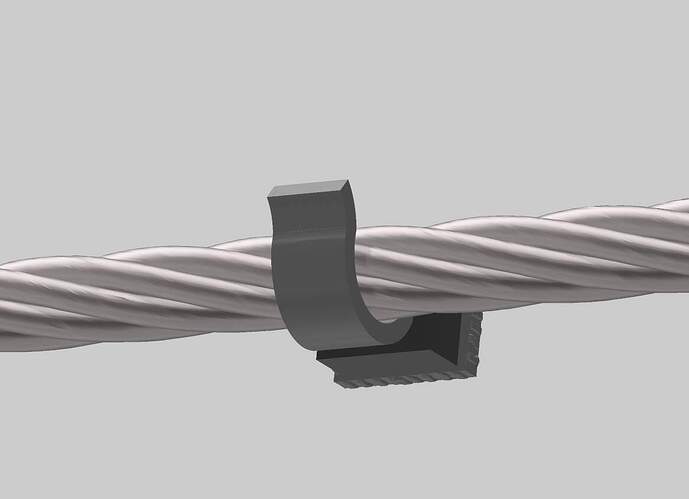

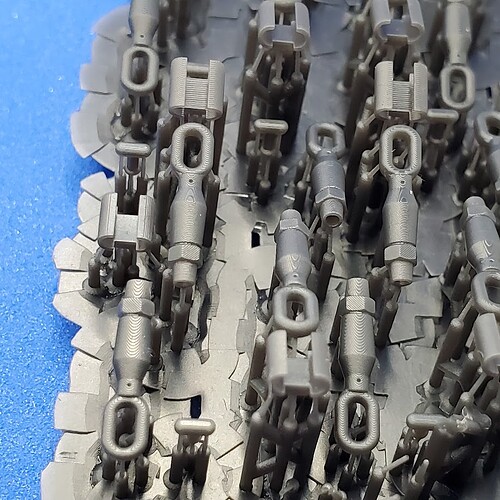

Modern US AFV tow cable eye CADded in 1/35:

Reference photos used:

Plan to use it for my M60 Slick and M1 IP projects.

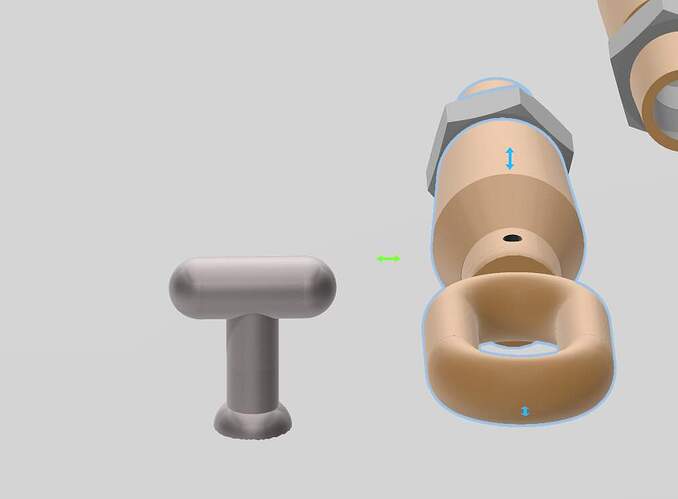

Following a suggestion, I plan to CAD and 3D print the front round “T” cable attachment and rear turret attachment bracket shown on Abrams also in 2 days.

They looks really good. Now we need the tow cable eyes from the M88A2.

Great work!

I think these will be on my next bulk order.

Damn! Nice!

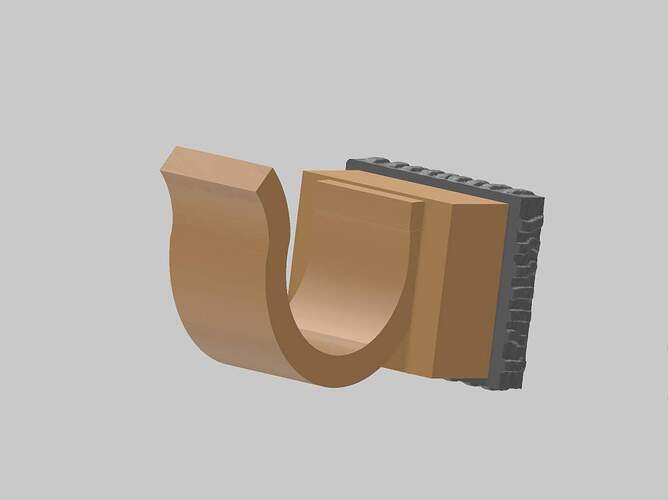

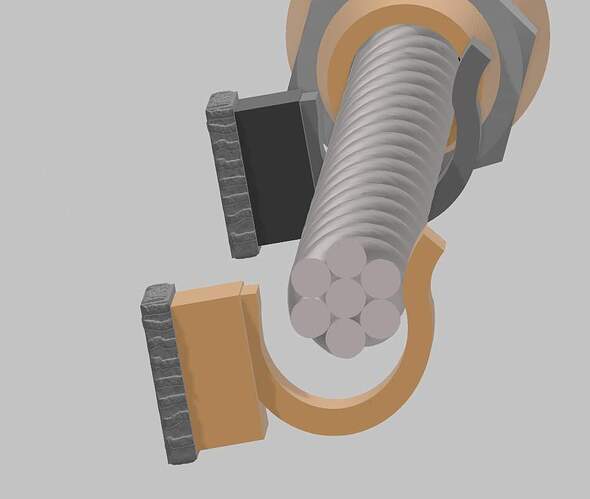

OK, so I CADded the tow cable mounting clip for Abrams series. It’s going to be a tiny thing with the clip thickness being less than 0.2mm in 1/35 scale… It will probably 3D print but removing the supports w/out damaging the thin part will be very tricky. And the carpet monster will easily eat it when mounting. ![]()

Reference photos used:

This is where I need to ask if a photo etch approach in a more flexible brass part would work as well? I know that PE is not your media, but worth a look by someone

Hi Stuart,

That’s what I said originally to the requester: PE or some Evergreen strips may work as well. However, I can see how bending and curving those tiny pieces accurately is much more painful. And you have to repeat the process consistently for 10 times for 2 cables.

Plus, attaching PE’s with superglue is more difficult than attaching resin parts that are already assembled. If these print fine, they’ll certainly be huge time-saver and adding much more accurate detail. Of course for those super detailers. ![]()

Yes. I hear what you are saying as one who tried the PE 50 cal links in 1/35 scale. Those took a long time even with a home made jig to curl the arms of the links in that scale. Wish the PE 50 cal links were still available as they looked so good.

I do wonder in this case if making a jig for metal bending would not be better option.

You can use other than super glue to attach resin bits. Liquitex Gloss gel medium or Gator Glue are two less of a mess and easily cleaned up with water for the excess.

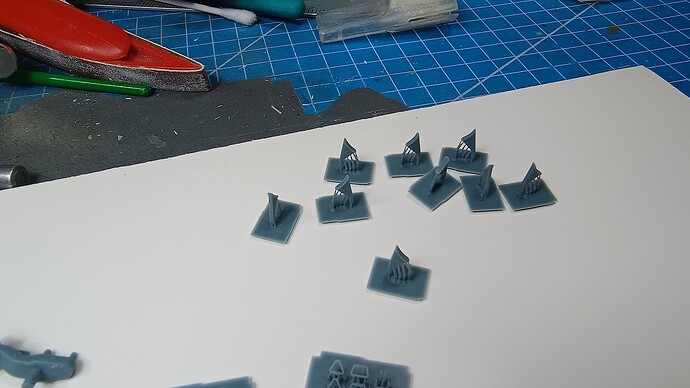

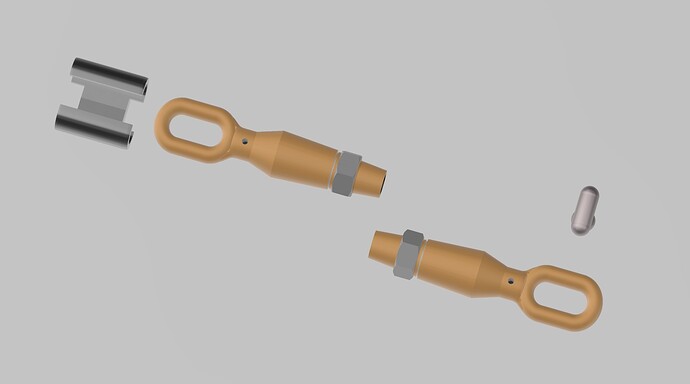

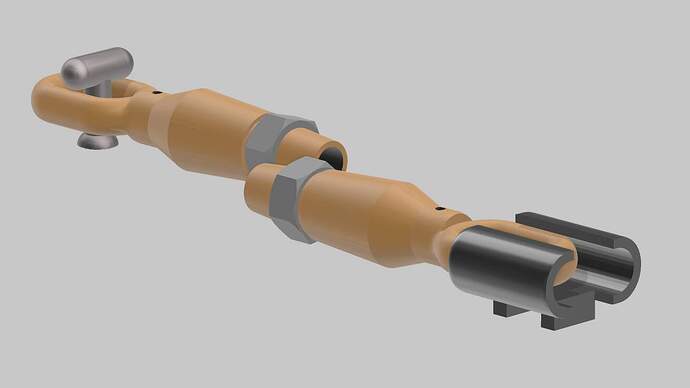

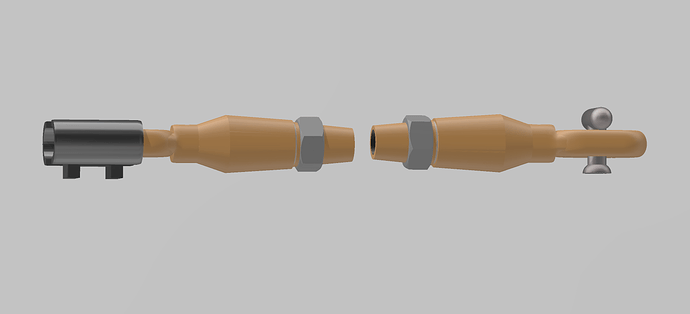

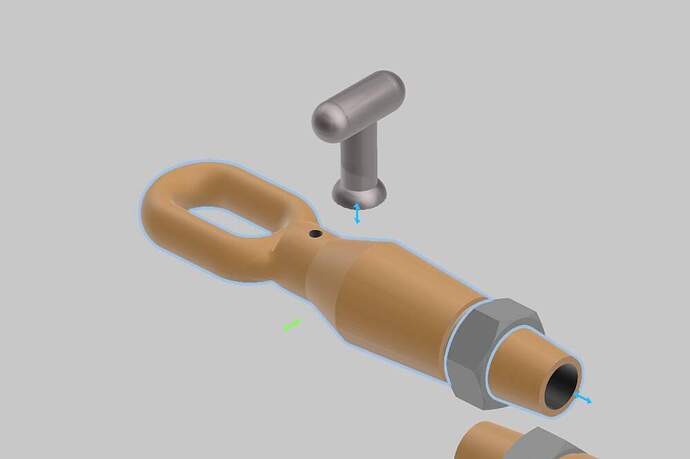

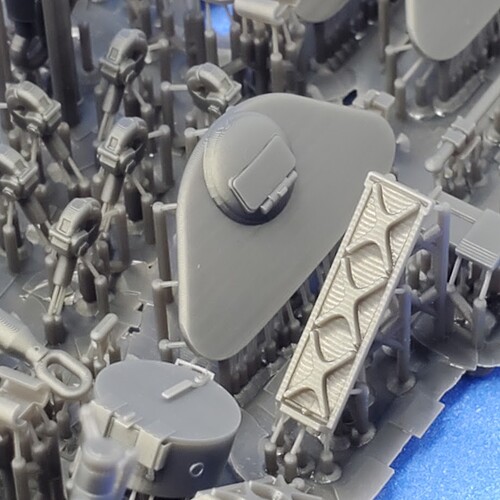

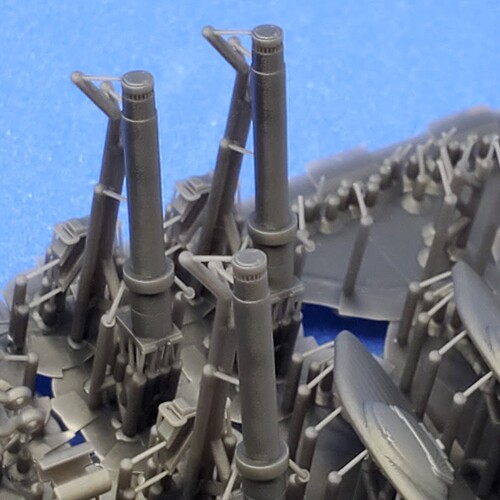

3D prints of my new designs (and some old) in 1/35 over the weekend.

Abrams cable eyes, attachment brackets, tow rings, tow pintle, tow bars, etc.:

Luckily, these were workable!

M60 driver’s hatch

Older type Abrams crosswind sensor:

And lastly, me pooping while web browsing on my mobile phone in 1/35 scale: