Very nice. They all look awesome.

Thats great!!! All parts needed for mechanics at works!!! great idea for my future wrecker

Something for the children and to justify 3D printing for my family. ![]() Non 1/35-related. Not my design. Downloaded STL from cults3d. My son was happier to play Mario Cart.

Non 1/35-related. Not my design. Downloaded STL from cults3d. My son was happier to play Mario Cart.

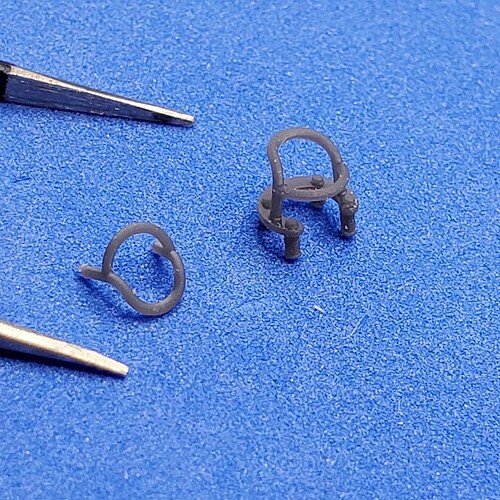

1/35 Leopard 2A5/6 blinker cage CAD done!

Should fit Border, RFM, and Tamiya offerings. Didn’t measure the Revell parts however.

Depicted weld seams even though they won’t show up in 1/35. Maybe not in 1/16 either…

Making the top protector part available as a separate file, too.

Uploading it to my cults3d page for STL purchase.

Reference photos used:

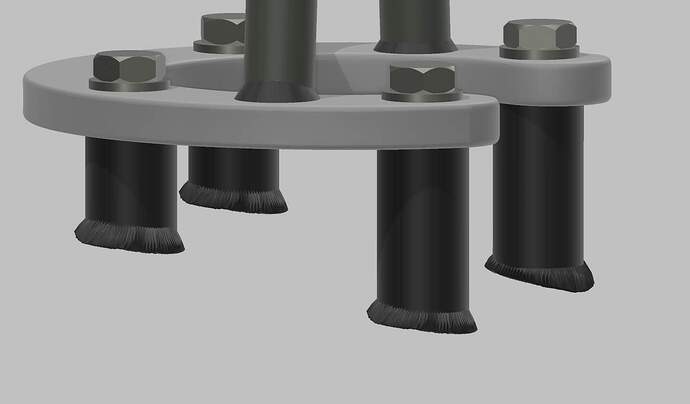

And T-Rex’s super expensive parts in 1/16:

Well, these will be in my basket once I start my 26M

Just saw in a couple of reference photos that there’s a hole at the base for an additional leg. So I updated my CAD accordingly.

Amazing.

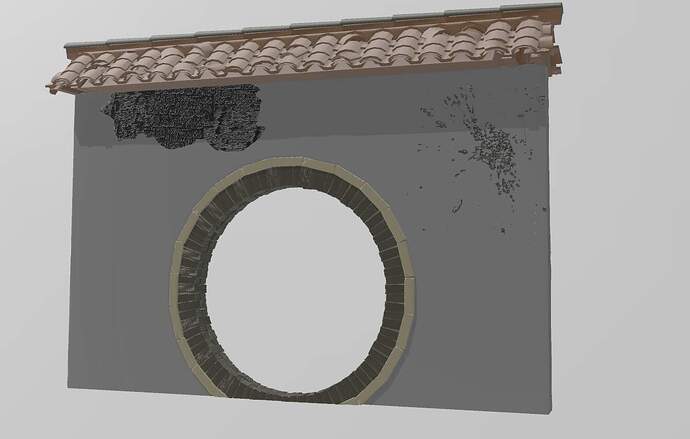

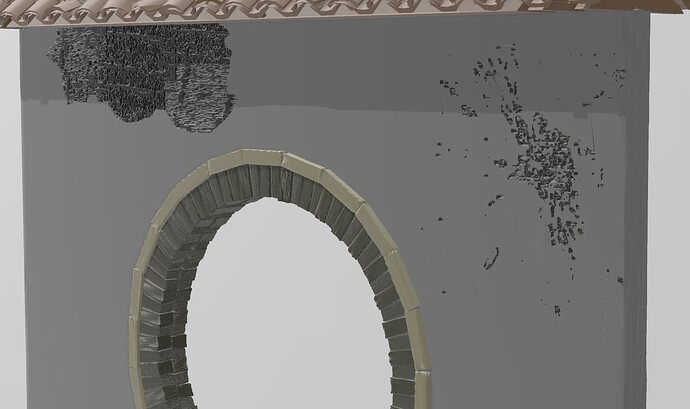

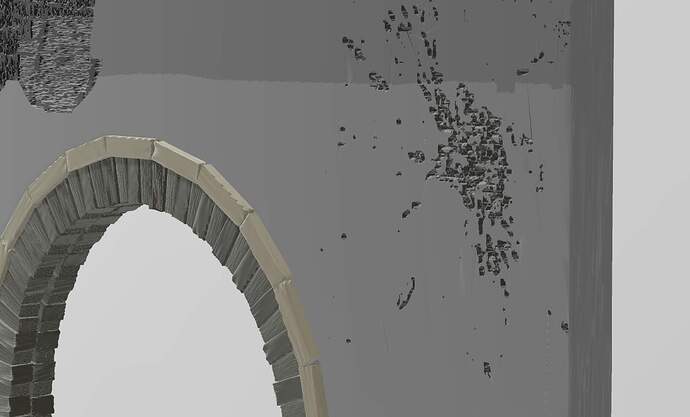

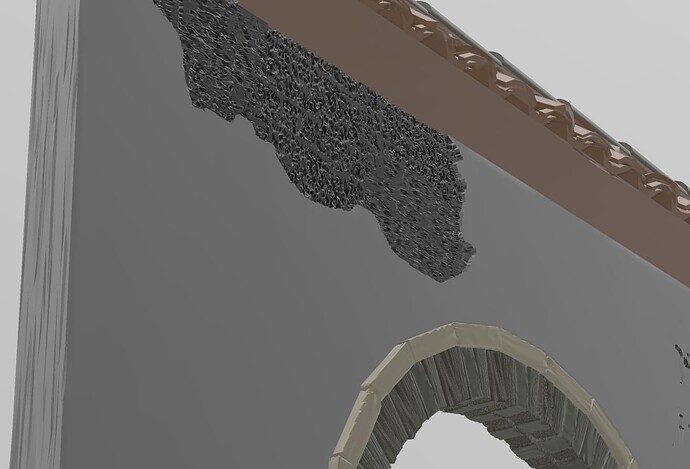

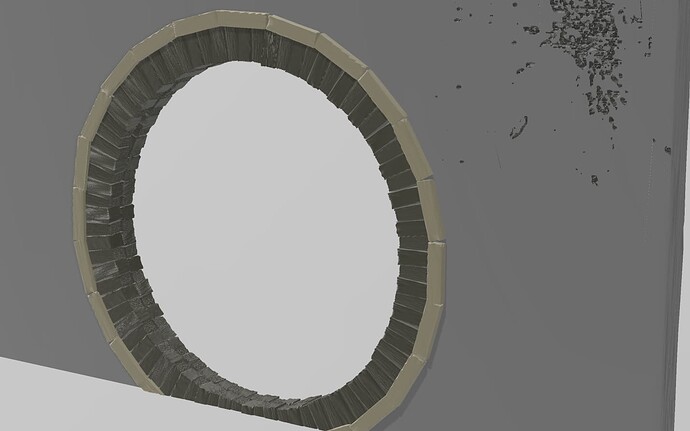

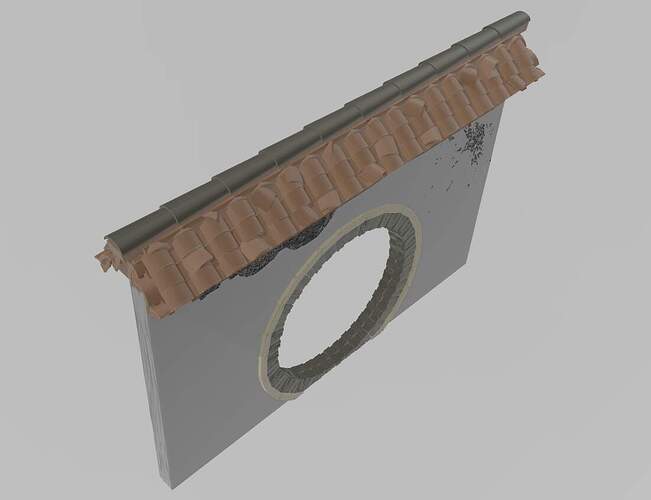

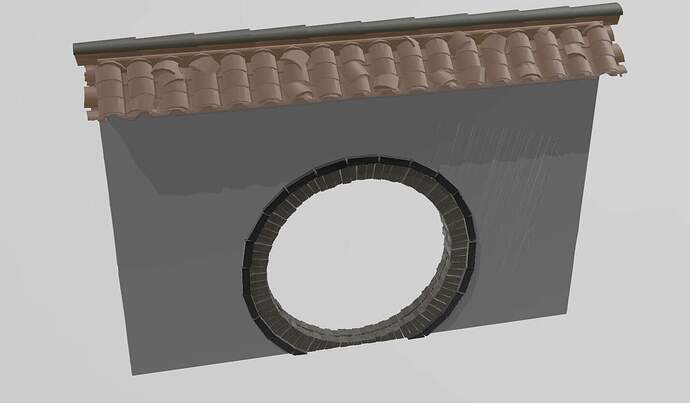

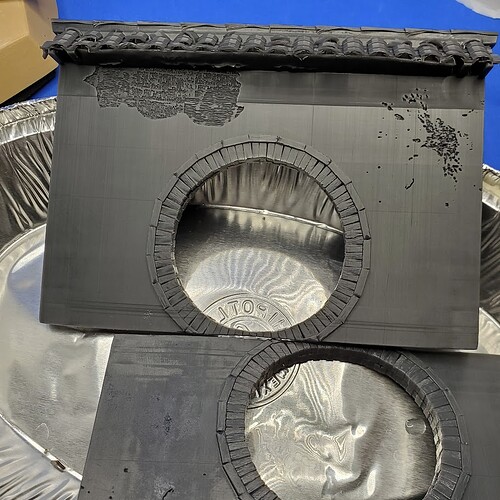

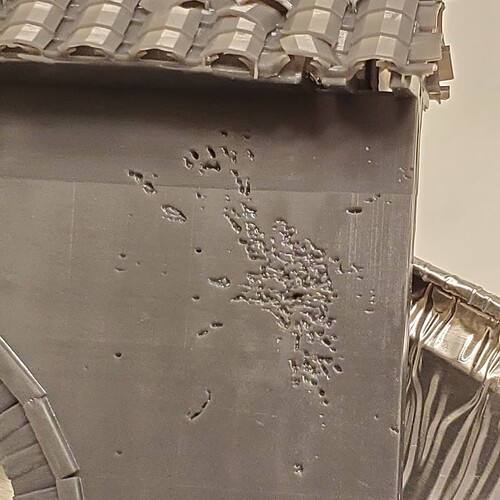

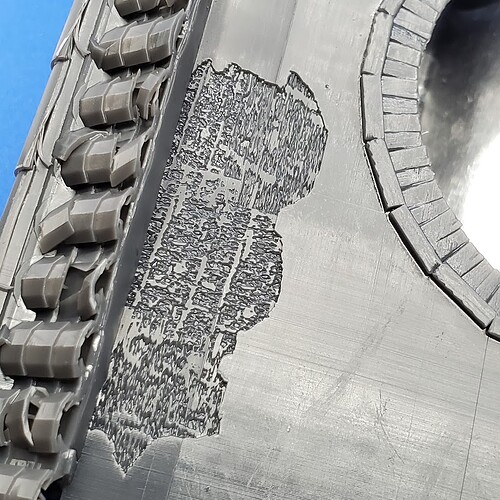

First time making a structure for a vignette or a diorama. Inspired by the “Animal Mother” scene from Full Metal Jacket (1987).

Too many polycounts and organic details kept freezing my CAD software.

Used ZBrush Lite and 3D Builder to make this in 1/35.

Tiled roof parts were borrowed from: https://www.fab.com/listings/a1d80e25-cf85-48b9-81d1-843340b4d9de. Licensed via sketchfab.

Reference photos:

Very interesting and cool. While you could print the wall and I get trying, I think using another material might be more ideal (cheaper etc) and all the details be 3D printed.

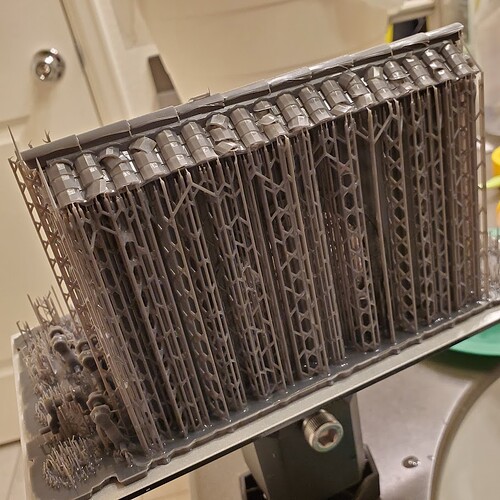

Most recent 3D prints:

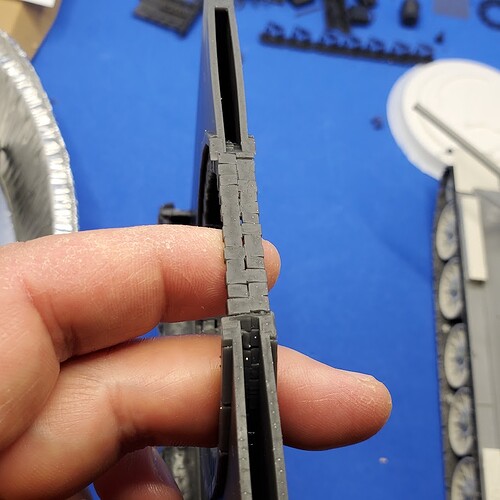

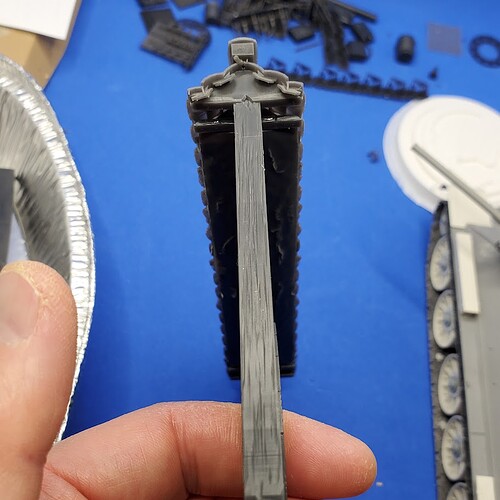

Concertina razor wires in 1/35:

10 strands loop:

4 strands loop:

Taking the supports off of these was a huge pain!

Traffic cones in 1/35:

Drip pans:

Choke block:

Homer buckets and choke block:

Homer bucket lids zoomed:

Leopard 2A5/6/7 blinker cage in 1/35:

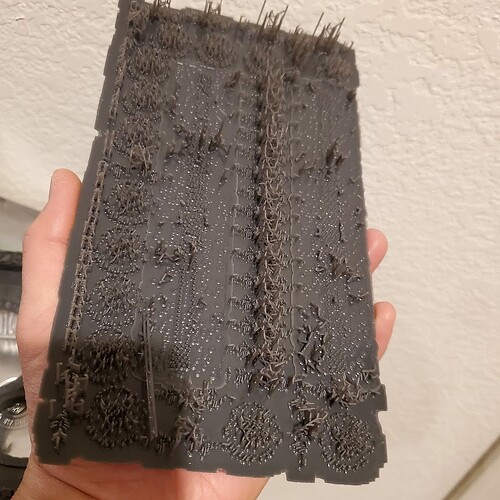

The Full Metal Jacket “animal mother” scene-inspired wall is 3D printed in 1/35 - used Elegoo Saturn 2 (8K resolution). Took 11 hours to print after 1 hour of slicer prep and 5 hours of CAD art work and research. It’s the biggest thing I’ve 3D printed so far:

With a Dragon US tanker figure:

Used up about 1/2 of the resin bottle (1000g) for supports and build plate:

I am going to offer this for sale to Armorama folks here first before going over to the FB land.

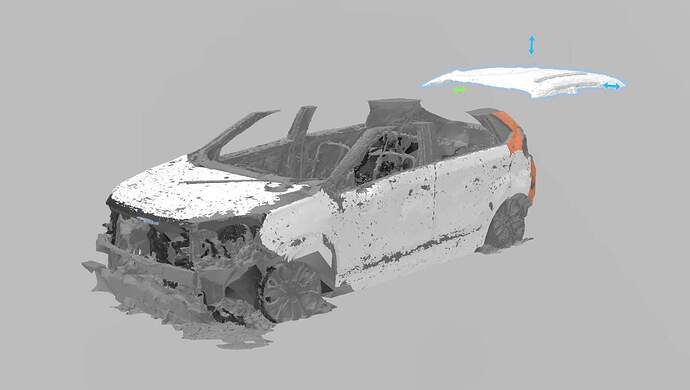

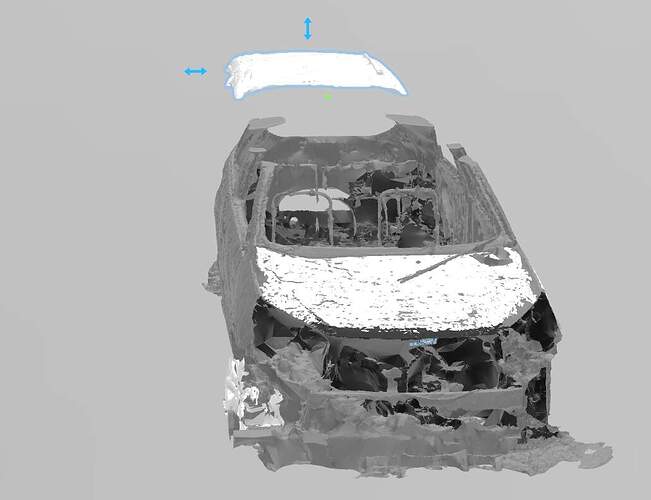

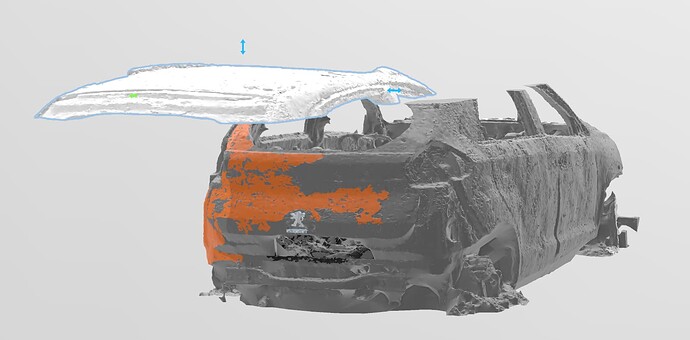

Also resumed some work on a modern burned car, which I wanted to do 2 years ago. Not that I have other ongoing projects and prints…

Started the base with this: “Lviv Missile Attack. Burned And Destroyed Car” (Lviv Missile Attack. Burned And Destroyed Car - Download Free 3D model by Serhii Revenko (@r.sergey01) [5cdf33c] - Sketchfab) by Serhii Revenko is licensed under Creative Commons Attribution (Deed - Attribution 4.0 International - Creative Commons).

I’ll be adding more details and make certain parts thicker to be 3D printable in 1/35. WIP:

The original designer’s renderings by using photogrammetry:

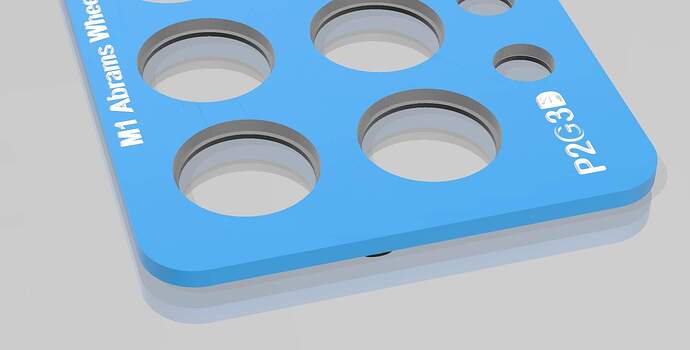

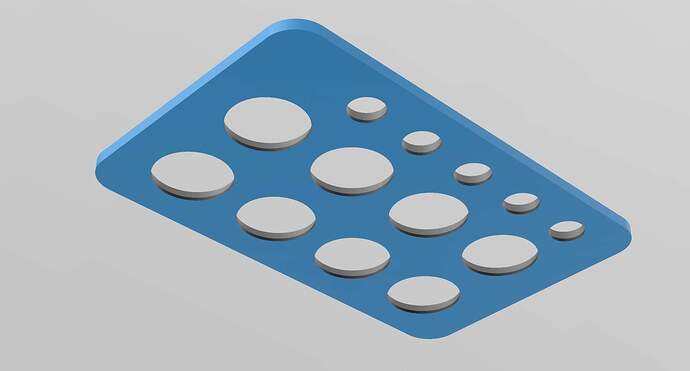

Nothing too fancy. Wheel mask for M1A1/A2 Abrams tanks in 1/35 for 3D printing. Suitable for both FDM and MSLA 3D printing.

Measurements based on RFM kit parts. Spare your time for responding with some circle stencil tool photos. I KNOW that works, too. Don’t waste your time on that subject please.

This one works similarly to Quick wheels items.

Uploading to my cults3d page.

I’m a fan of both techniques and this particular set. ![]()

I never find it a waste of time to help improve a product or technique.

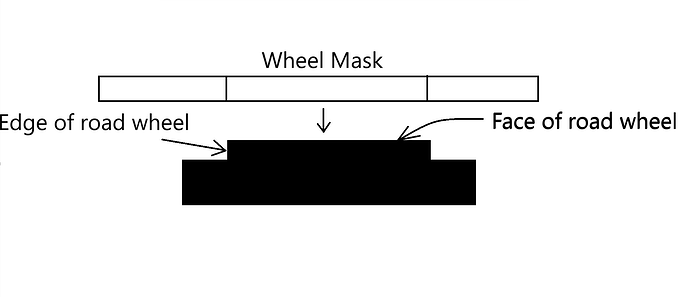

My issue with the mask as I see it is that it’s too thick. In the sketch below you see the road wheel painted black - ready for the mask. However, when the mask is applied, it also obscures the edge of the actual wheel, leaving it black, while only the face of the wheel receives the second color.

I find the advantage of photo-etched, vinyl, or home made masks made from brass shim stock is, they are much thinner and don’t obscure the edge of the wheel nearly as much, letting it receive new color as well as the face.

How thin can you get with a 3D printed item?

You bring up an interesting note with data. Ones that I do not need to see are people simply posting plastic stencil photos and [condescendingly] say they don’t need a wheel mask. Different story.

I’ll do some more measurements tonight and see how much of “loss” is there.

To answer your question, MSLA print can be about 0.1mm thin without breaking. Of course, ABS like solvent based resin is stronger than a water soluble resin. FDM can be 0.2 mm thin and be durable. This also depends on the type of material - ABS plastic more flexible and stronger than PLA type.

A typical PE is about 0.15 mm. The edge of the 1/35 Abrams wheel you refer to is about 0.2mm in thickness so you’re looking at a loss of 0.05mm in detail, which is nearing micro measurements only visible in significant magnification. I’m not sure that is much of advantage. My design’s flap near the edge is about 0.2 mm so it would cover the edge in theory? Quick wheels products are similar in the approach.

In theory, this is a topic of debate but in reality, it may not make difference. Plus, gravity or capillary action of airbrushed paint may cover the 0.05mm (hair thin) surface we’re talking about.

Great idea

So I did some measurements to confirm that advantage of PE, vinyl, or brass shim is almost negligible. 0.04mm to 0.1mm difference in thickness if printed in FDM. Basically no difference if printed more thinly in MSLA (resin).

The flap edge that touches the wheel edge is around 0.24 mm.

I cleaned up one hole of my fresh off the FDM printer and inserted an Abrams kit wheel - for FDM 3D prints, “brim” needs to be trimmed off:

There may be 0.05mm space between the mask’s hole and the kit part for the paint to go in?

Like I said, a typical PE or brass sheet’s thickness is around 0.15mm. One that I picked up from a Mirror model tractor kit I was working on read 0.2mm -

If the Abrams road wheel’s edge is 0.2mm high, the PE mask offers no advantage. 0.04mm thickness is thinner than a mid-sized hair. I doubt that it makes a difference when painting.

My thinnest shim stock is .005 inch. I’ve been fortunate in the past to find punches I could use for various wheels so I still think it does give an advantage on most wheels. And I have to say, using the Meng PE mask on Bradley wheels wasn’t a true test as I sand the lips off of all Bradley wheel anyway. I’m sure you’re right, though - PE might be too thick to make a difference on other types of wheels, but I still like shim stock. It was worth investigating in any case. Your original images made the masks appear thicker than they really are.