Hello, considering these tools can be as expensive as a model, I wonder if it’s possible to bend them without tools or I’m obligated to get one.

Thanks for your answers!

You can use flat nosed pliers and other such tools, but it is harder and you may not be able to make small bends.

I used to bend with tweezers and pliers but as has been said by @HeavyArty this is hard to do with small bends.

I bought this https://www.amazon.com/Trumpeter-Photo-Etched-Parts-Bender/dp/B00B8457PA

For $30 and it transformed my PE building

You can anneal parts by heating them in a flame first. This makes the “brass” more pliable and much easier to bend or fold.

Just don’t overdo it on the small parts.

I used to use a rigid straight edge clamped to my work surface with carpenters clamps, it works but it’s also cumbersome. I understand trying to enjoy this hobby with a limited budget but a PE bender will save you a lot of frustration and you’ll appreciate it’s use in the long run. I have “The Bug” from the Small Shop and it’s a dandy little bender, it was, as you said, a $50 investment but well worth it. Your models will look better and you’ll feel cool for having one, sorta like your car runs better when you wash it. ![]()

Cajun ![]()

Given just how common PE parts are now included in the kits, themselves, and not just as separate AM sets, getting a PE bending tool really makes sense. It’s not such a luxury nowadays as it might have been just a few years ago.

Terry’s suggestion for the Small Shop “Bug” is a really good one. I also have one and can do probably 90% of all PE bending tasks just using it. It’s a good investment.

This is the Small Shop Bug in action, bending up the front fenders for an AFV Club Churchill kit:

And the final result:

All the bending for these was done with just the Bug.

Simply beautiful PE work! The soldering is fantastic

The soldering is still my weakness, but that is simply a matter of practice and repetition. Fortunately I have not had to deal with any very complicated pieces yet, but I have a Trumpeter 20mm Flak 38 with a brass gun shield glaring at me from the shelf who’s gaze I am trying to avoid.

I tried soldering once I was horrendous. I too have some kits staring at me that will need soldering but I am not brave enough to try yet.

I have some scrap brass sheet I’ll use to learn soldering I think

+1 for The Bug. For the price of a kit it’s a must have. I do 99% of my PE work with it and it handles everything with ease. With PE included in almost every kit now, you have to have one.

It all depends on your needs, the complex work above by @SdAufKla does indeed require a dedicated tool (and a lot of skill!), however simpler photoetch parts, with engraved folding lines can be dealt with the help of some flat nosed pliers as said also above.

In any case, the small RP Toolz bender is usually a more affordable and still acceptable alternative

I forgot about old Rado.

there’s also the Trumpeter Master tool, you can find them at a good price if you shop around, especially the smaller ones…they do their dirty job

Thanks! With the proper tools and techniques this is within the capabilities of most modelers.

The Bug is worth every penny. When you clamp a small piece to fold it stays put. I can’t remember how many pieces went “ping” from bending with hand tools and were devoured by the carpet monster before I invested in The Bug years ago. No more nose on the ground and butt in the air searching the floor for tiny little parts. LOL

I know in another thread you recommend some tools to me for PE when I do my first ship later this year I plan to pick some of them up and practice soldering on scrap brass sheet

Yeah the trumpeter one bends. It’s not good enough when you need that former plate to be strong. I know I used to have one.

didn’t expected to get so much answers, I’ll seek to get one for my birthday(or ask my dad nex moth but I’m unsure he’ll say yes). I plan to use it for tanks such as meng T90 or trumpeter T72.

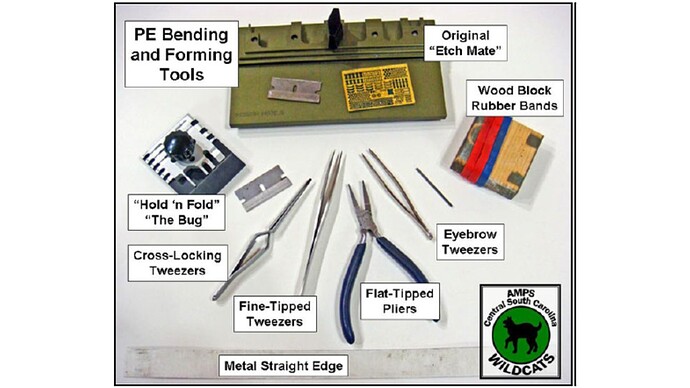

Even starting with a set of flat-nose pliers will get you quite far with small PE parts that only need a single bend or two. A small steel ruler and a piece of glass or ceramic tile along with a single-edge razor blade will also serve for slightly larger simple PE parts.

Sometimes large tweezers (with non-serrated, flat tips) are all that needed, especially for really small PE parts, perhaps with another pair of tweezers for manipulating them.

Here’s a picture of some of the purpose made and general tools that you can use for forming PE.

Most are self-explanatory.

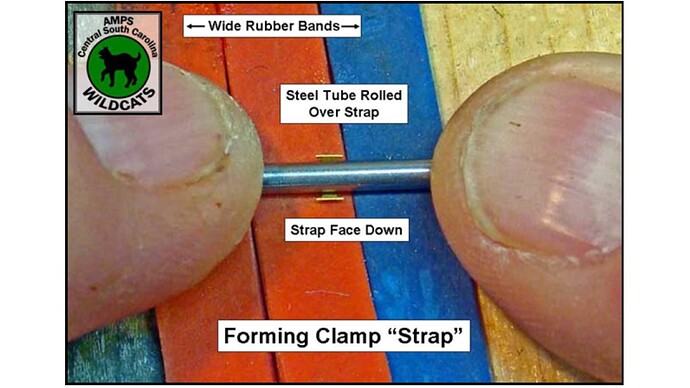

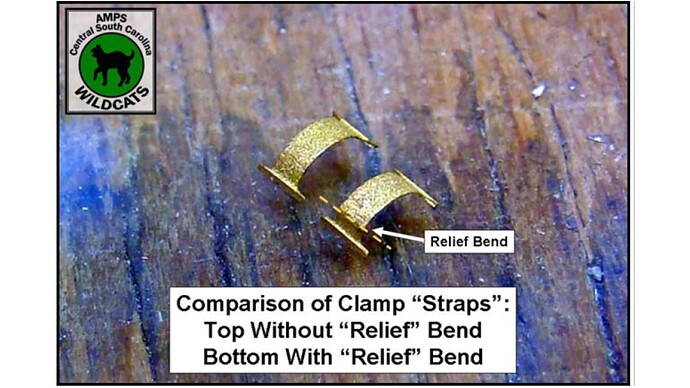

The wood block with the wide rubber bands and the small drill bit are expedient tools that can be used to “roll” curves into small PE parts. The diameter of the drill bit and the pressure used to roll it across the PE part as it rests on the rubber surface will govern how tight (the size of the radius) the curve or bend will be.

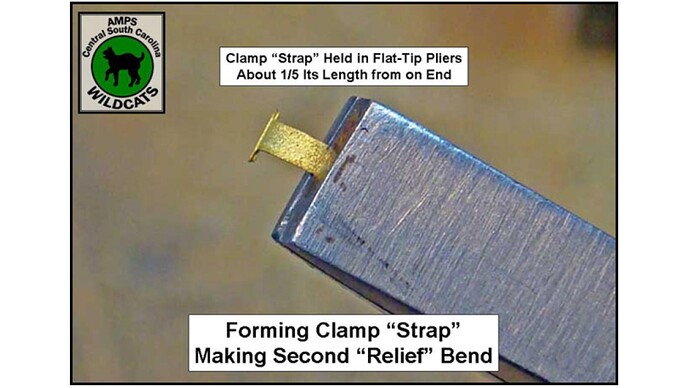

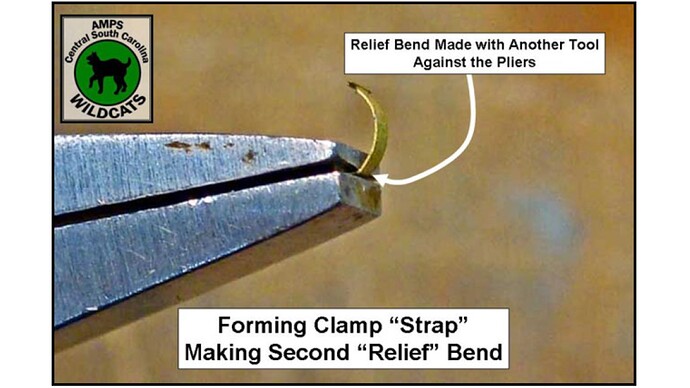

Here’s an example of this expedient curve forming tool and a pair or flat tip pliers in use to form one of the pieces of a PE workable tool clamp.

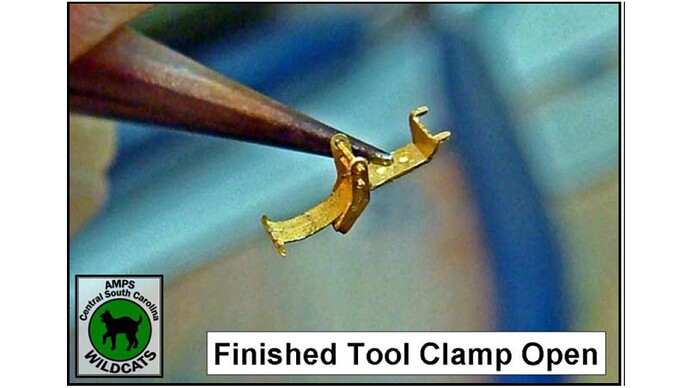

Here’re the finished tool clamps:

The functionality of the clamps might seem pointless. However, if made to work, they will enable you to paint and finish the tools to a high degree and then add them later to the model - creating variations in the degree of weathering and wear on the tools and the vehicle.