Intro and Background

The gloriously handsome BMW 507 Coupé was initially the brainchild of an American, the car importer Max Hoffman who, in 1954, persuaded the BMW management to produce a roadster version of the BMW 501 and BMW 502 saloons. His idea was to plug the contemporary gap between the expensive German Mercedes-Benz 300SL and the cheap and relatively under-powered British Triumph and MG sports cars.

BMW engineer Fritz Fiedler – of pre-war BMW 328 fame - was assigned to design the rolling chassis, using existing components wherever possible. Early body designs by Veritas-BMW performance-car specialist, Ernst Loof, were rejected by Hoffman, who found them unattractive. In November 1954, largely at Hoffman’s insistence, BMW contracted industrial designer Albrecht von Goertz to style both the BMW 503 and the top-end 507.

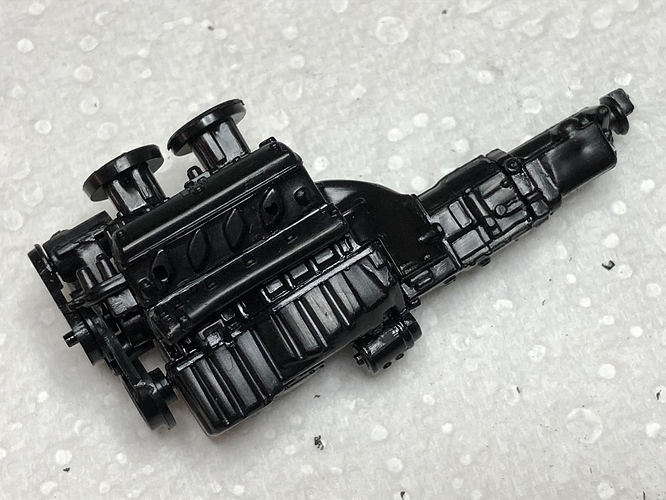

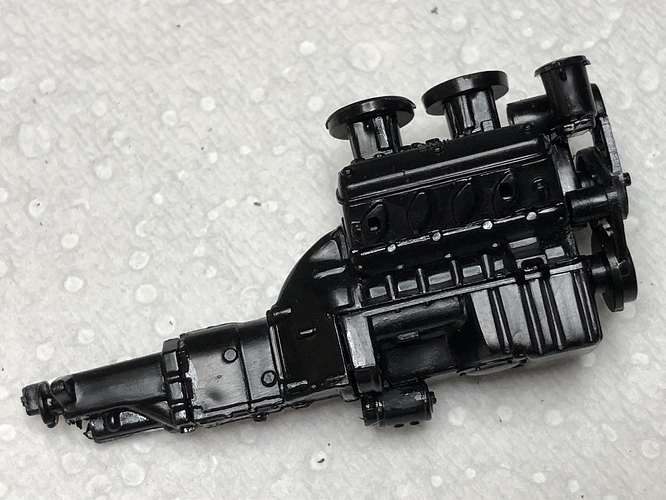

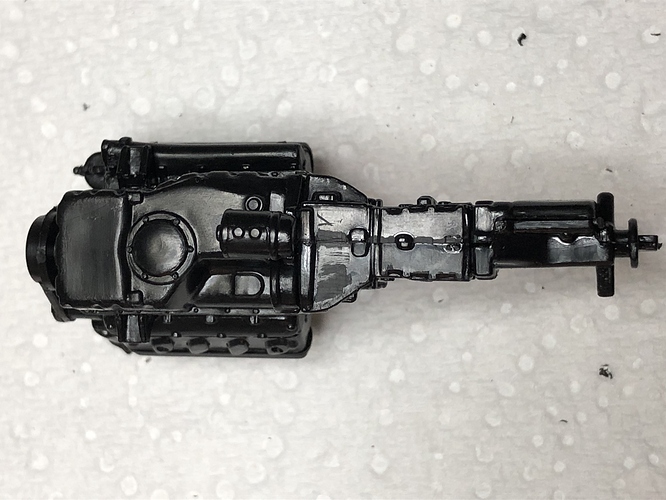

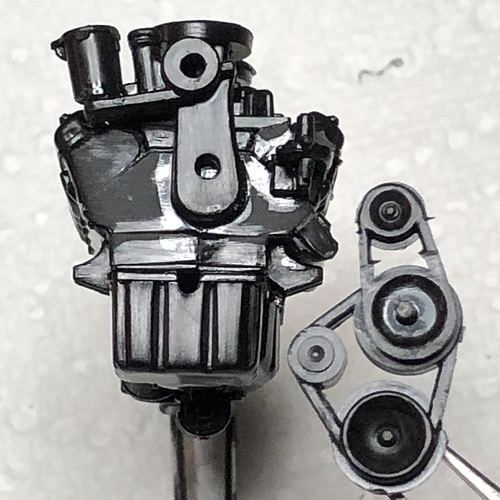

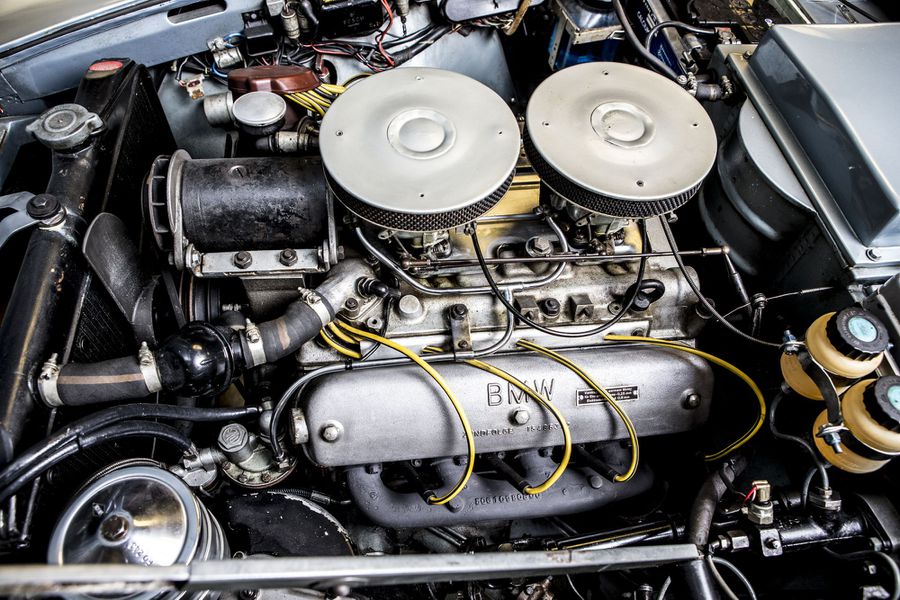

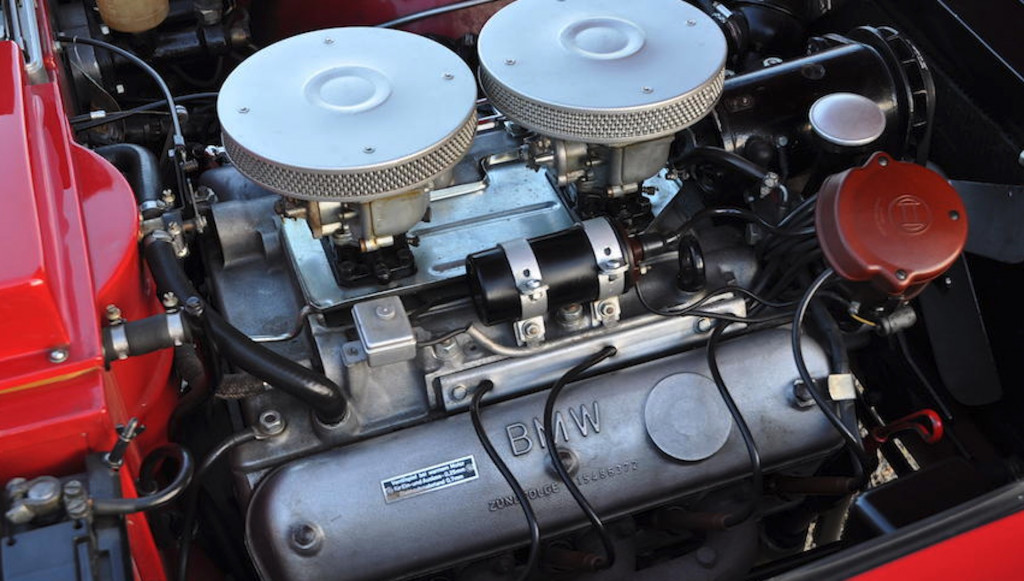

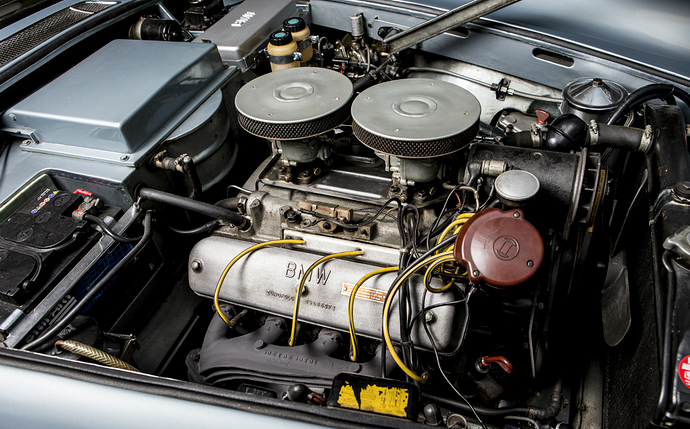

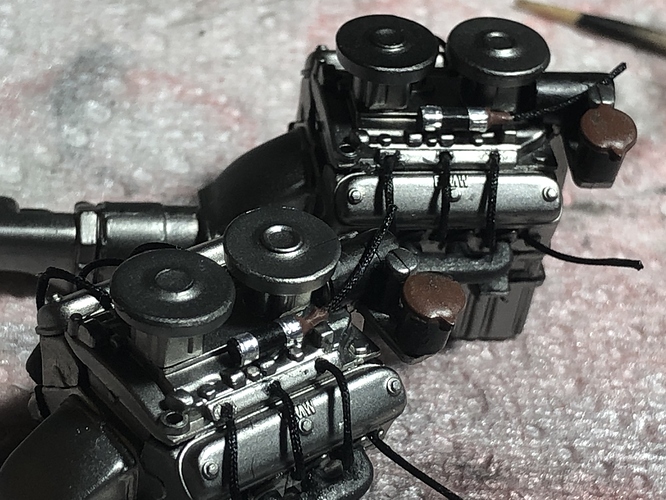

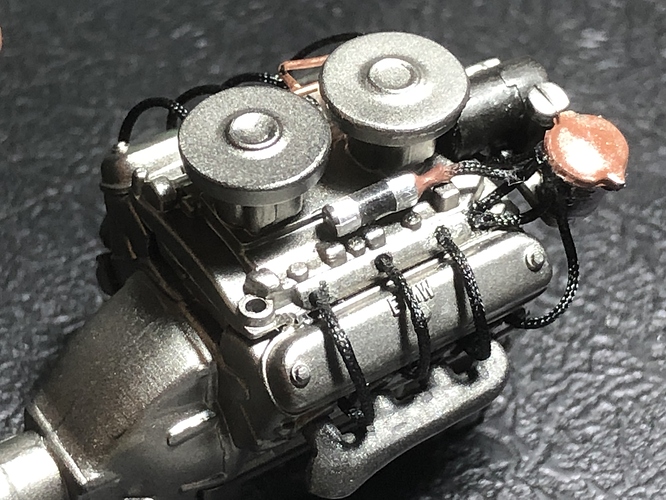

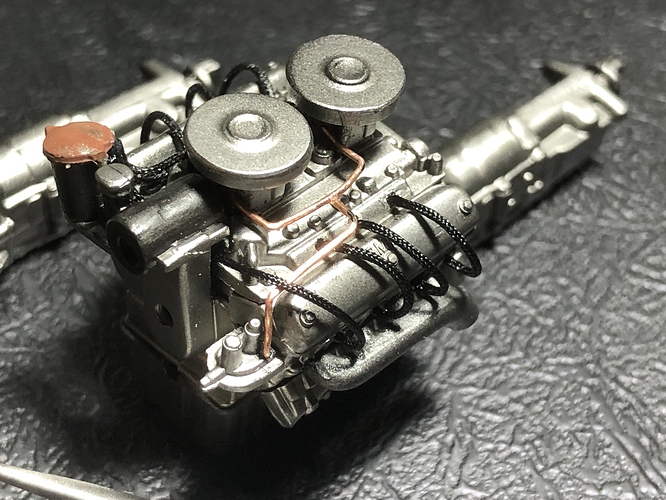

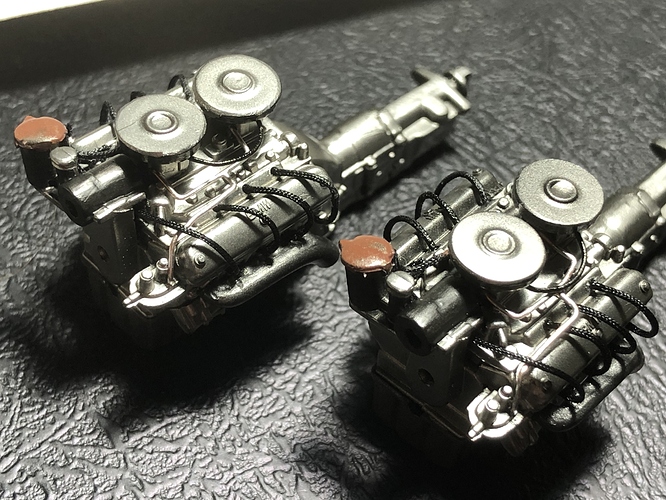

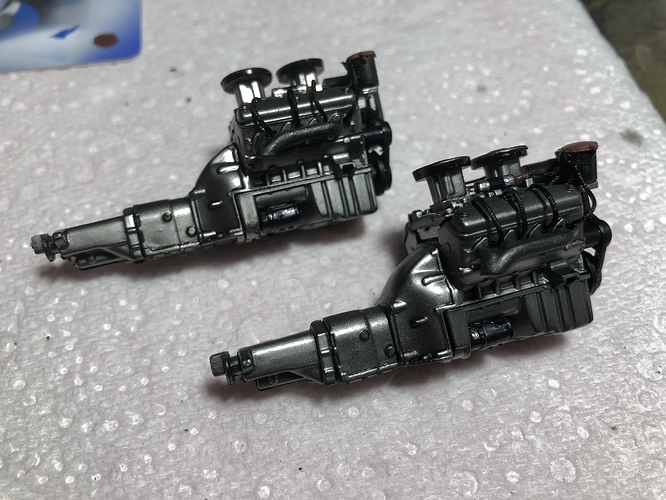

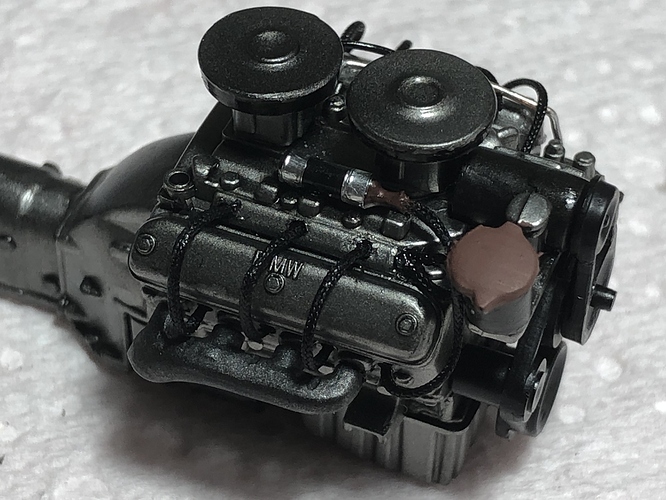

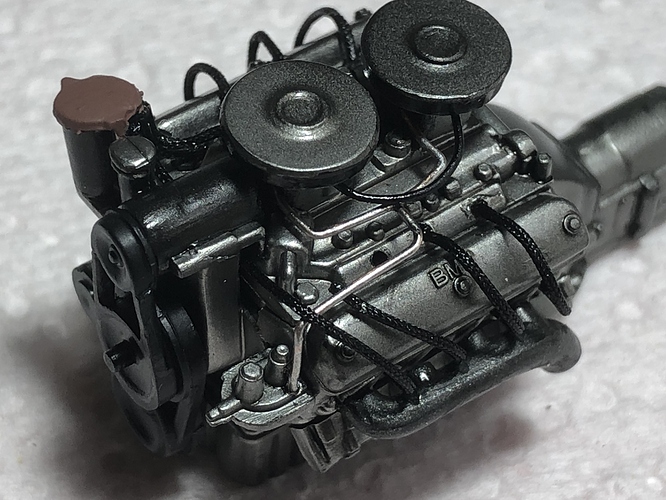

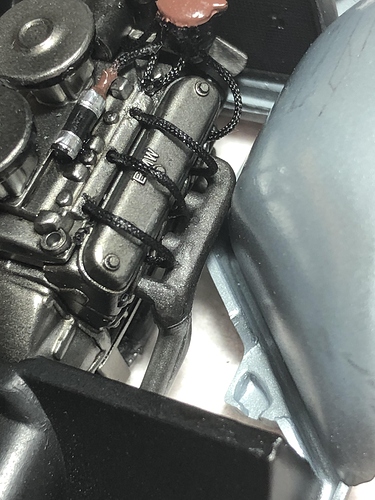

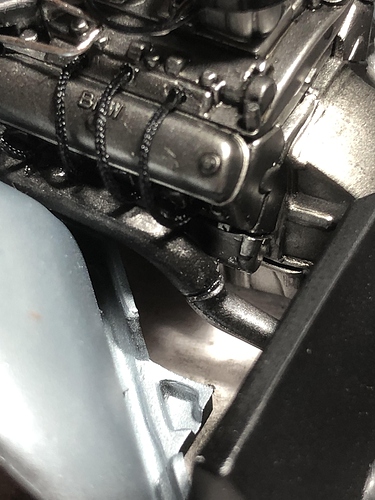

The BMW 507 Coupé’s power unit was an aluminium-alloy pushrod-operated overhead-valve V8 unit, displacing 3,168 cc (193.3 cubic inches). It breathed through two Zenith 32NDIX two-barrel carburettors, and featured a chain-driven oil pump, high-lift cams, a different spark advance curve compared to the associated saloon models, polished combustion chambers, and a compression ratio of 7.8:1. Power output was claimed to be 150 metric horsepower (110kW) DIN at 5,000rpm. This impressive-looking – and sounding – power unit was mated to a close-ratio four-speed manual transmission. The standard final-drive ratio was selected as 3.70:1, with options of 3.42:1 and 3.90:1 optional.

A contemporary road test of a BMW 507 with the standard 3.70:1 final drive appeared in the Swiss magazine Motor Revue, citing 0-100km/h (0-62mph) acceleration in 11.1 seconds and a top speed of 122mph - heady figures for 1956-57. Here indeed was a rocket ship for the public road.

The brand-new BMW 507 made its debut at the Waldorf-Astoria Hotel in New York in the summer of 1955 and production began in November 1956. Max Hoffman intended the 507 to sell for some US $5,000, which he believed would support a production run of 5,000 units a year. However, production costs of this svelte new German beauty ran away with the project, and the German market price inflated relentlessly: first to DM 26,500 and later 29,950, which pushed up the US market price initially to $9,000 and then $10,500.

The 507 Spyder and Coupé’s undoubtedly startling looks attracted such celebrity customers as Elvis Presley (who owned two), and Hollywood movie director John Derek, while in Germany pre-war Grand Prix racing champion Hans Stuck and motorcycling star Georg ‘Schorsch’ Meier became prominent owners.

Despite having been conceived to revive BMW’s sporting image, and to drive brand perception and sales volume forward, the 507 failed to attract more than 10 per cent of the sales volumes enjoyed by its Stuttgart rival, the six-cylinder Mercedes-Benz 300 SL. Yet for many it was an infinitely better looking, more glamorous, lighter handling – and rapid – alternative.

Their sales difficulties with the 507 instead took BMW to the edge of bankruptcy. In 1959 the Munich company’s losses reached DM 15 million. The company lost money on every 507 built, and when production was abandoned late in 1959 only 252 had been completed, plus two prototypes. Fortunately for the Bavarian company, an infusion of capital from Herbert Quandt, and the launch of new, cheaper models (the BMW 700 and later the ‘New Class’ 1500) intended for a very different sector of the road car market, helped the company recover, placing it on the launching pad to its continuing success.- Collated from various sources

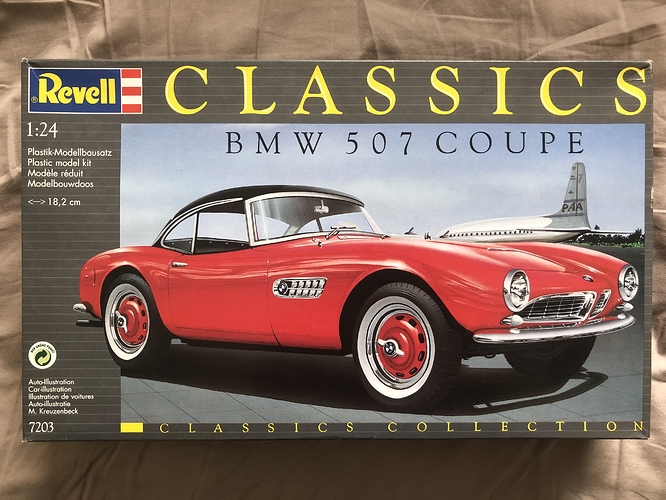

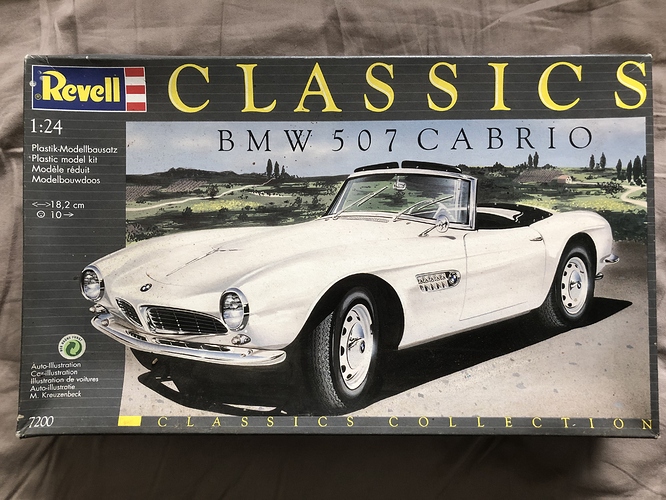

When I saw these 2 kits posted for sale in a stash clearance I was instantly drawn by the classic 50’s lines and chrome, and even though I knew nothing about the car, and had never seen them built or reviewed online, I snapped them up.

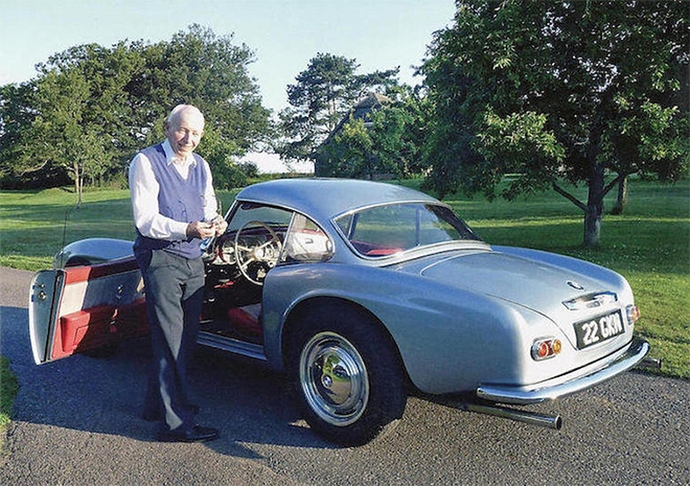

Doing some research to look at options for colour schemes, I came across a pair of very significant vehicles that would make a great little display pair.

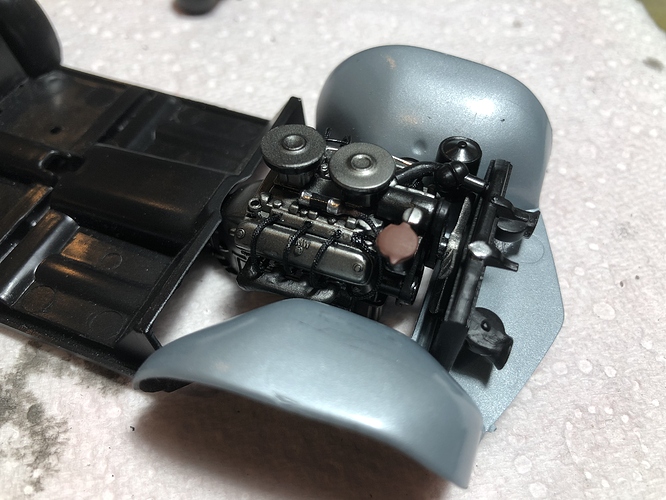

The first is the Coupe owned from new by the legend John Surtees, sold at auction after his death for almost 4 million pounds, in 2018.

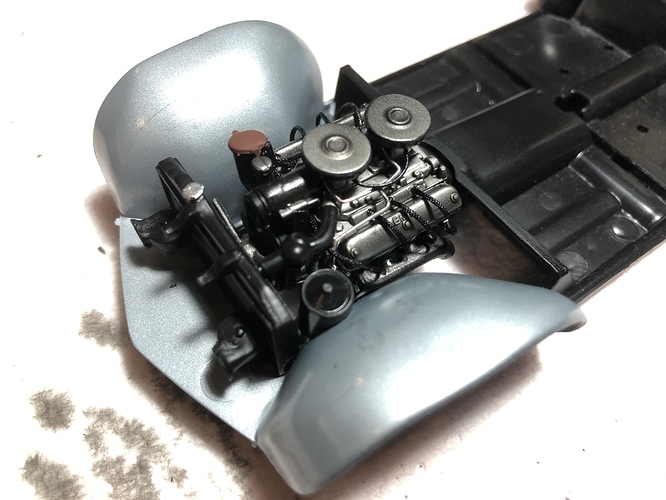

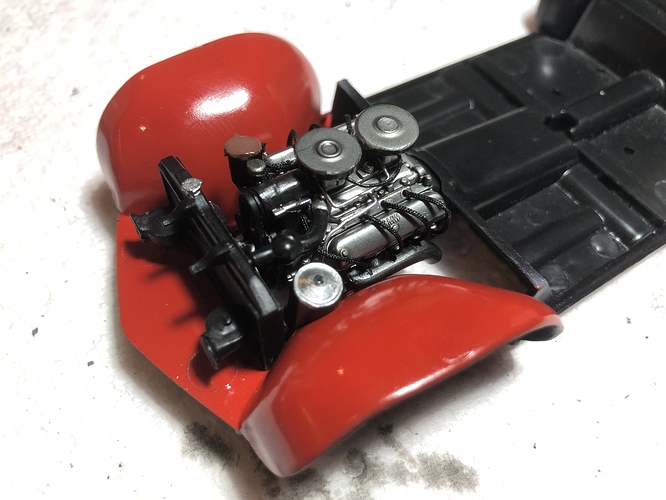

The second is the Cabrio owned by the car’s designer Albrecht von Goertz. This one was originally factory silver-grey the same as the Surtees Coupe, but was repainted in the 90’s, and I like the red body colour.

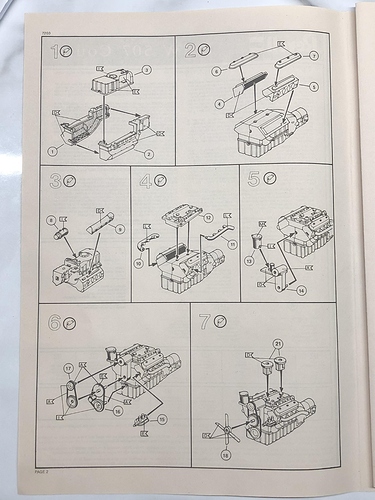

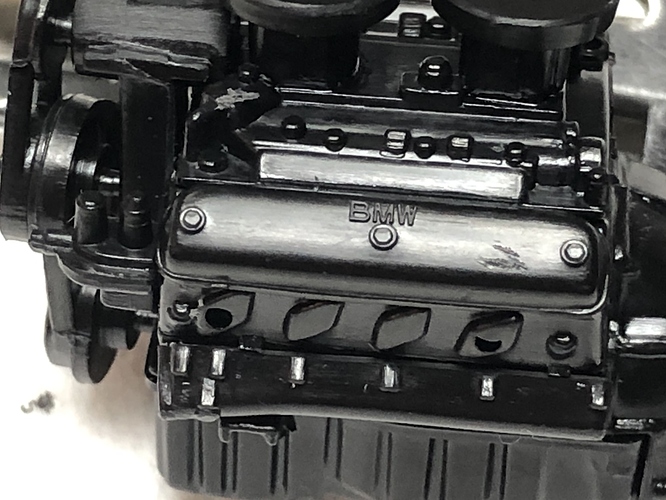

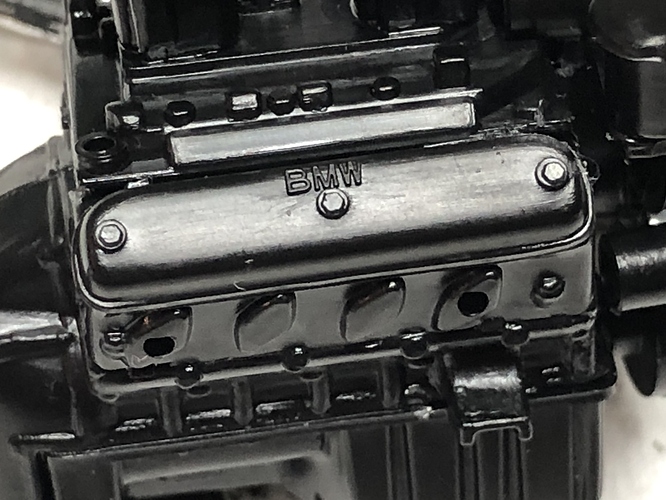

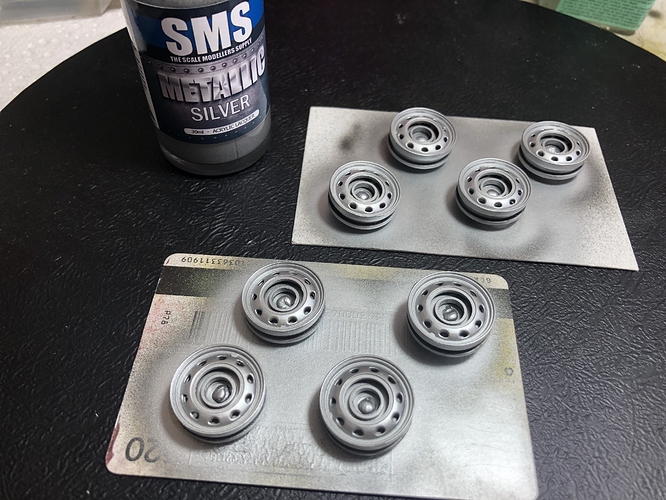

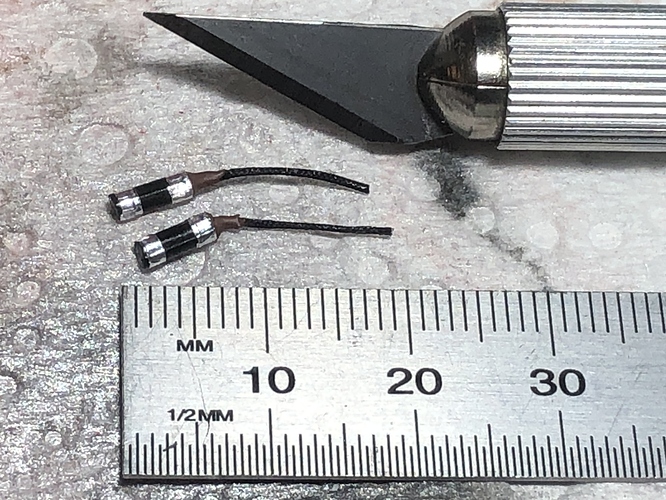

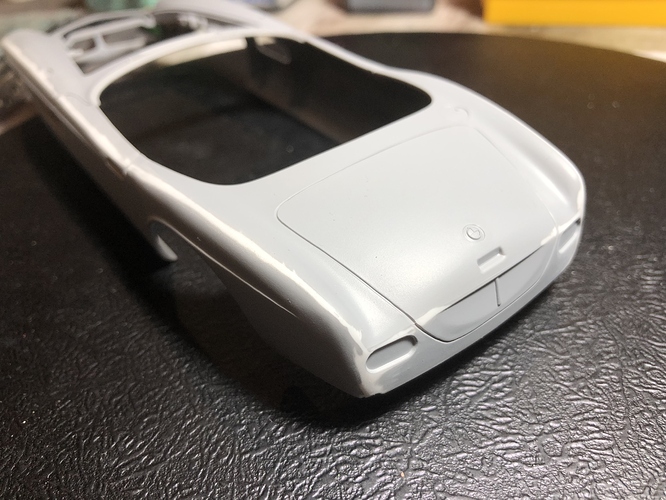

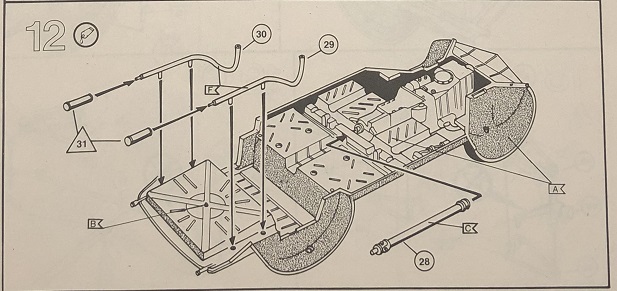

A quick look at the kit parts gives me some confidence, the plastic is nice and clean, very little flash and no sign of deformation. The chrome looks quite clean and consistent, and the window parts thin and clear. I will post up detail shots of the sprues and parts as I go.

I’m very much looking forward to working on these 2 kits, and as always please offer up any comments, advice and constructive critique along the way.

Cheers, D