Hi Fellow Modelers,

Got no replies on the last one, guess people have either lost interest, I’m just that darn good you’re all speechless (yeah right HA HA) or it was too short.

Hopefully the later is the cause. Please leave a comment and any suggestions. They’re most welcome. So, here’s a longer one.

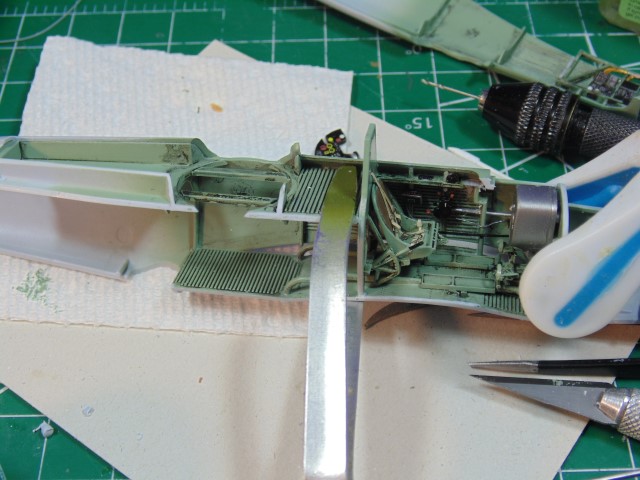

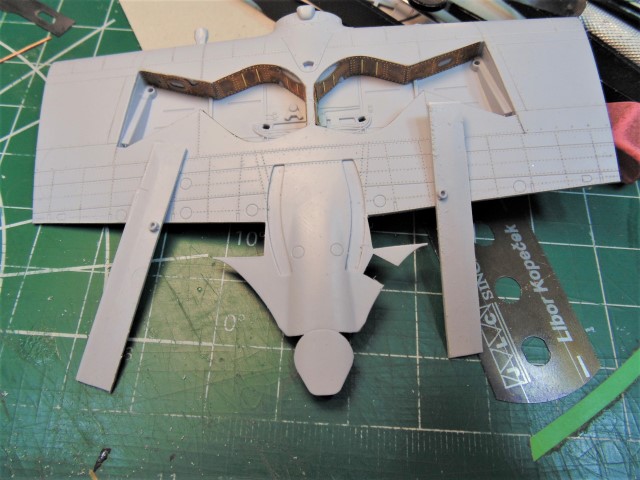

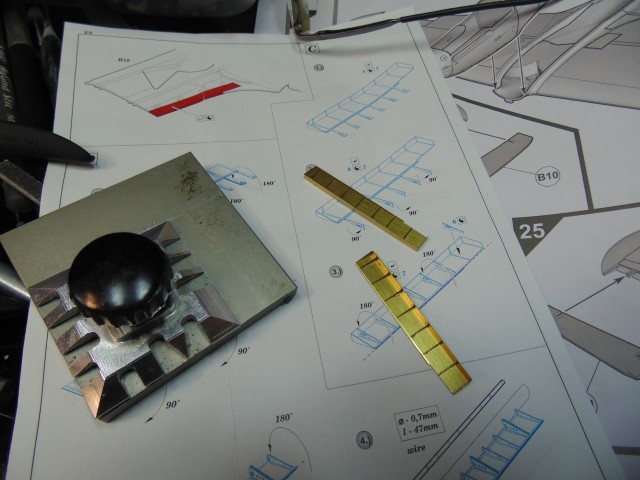

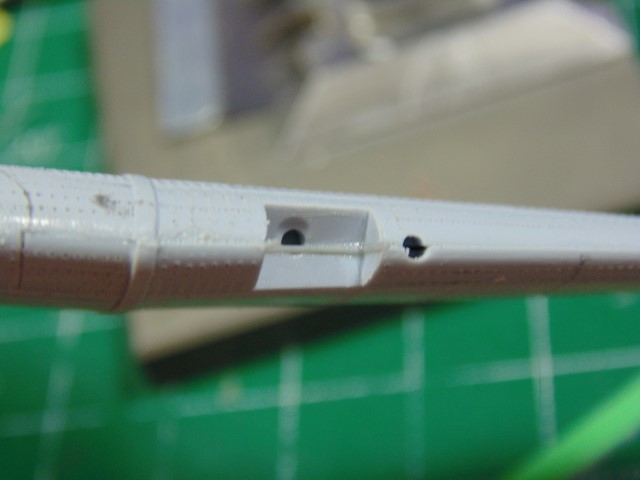

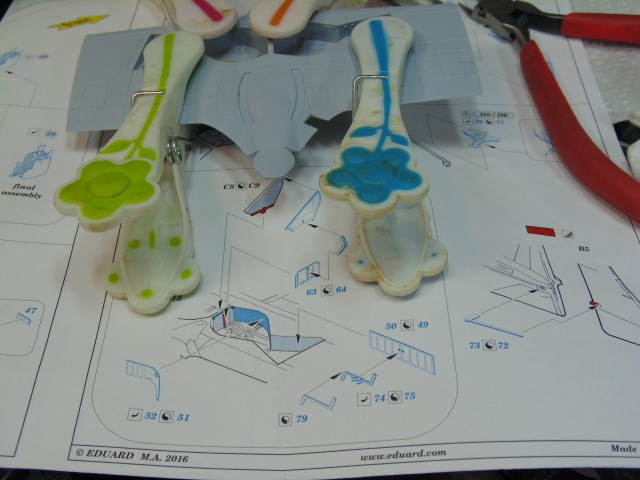

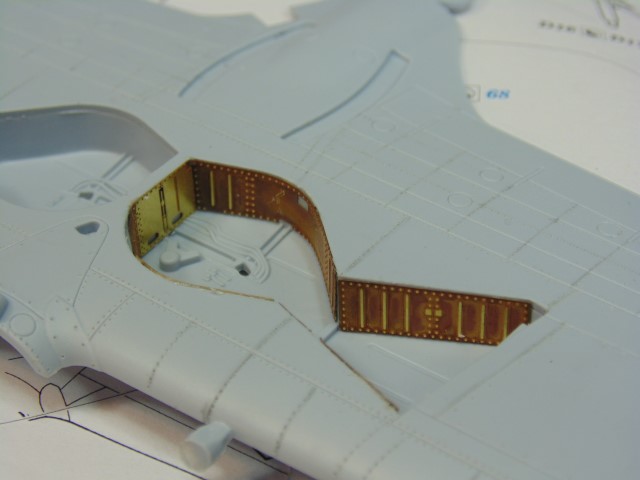

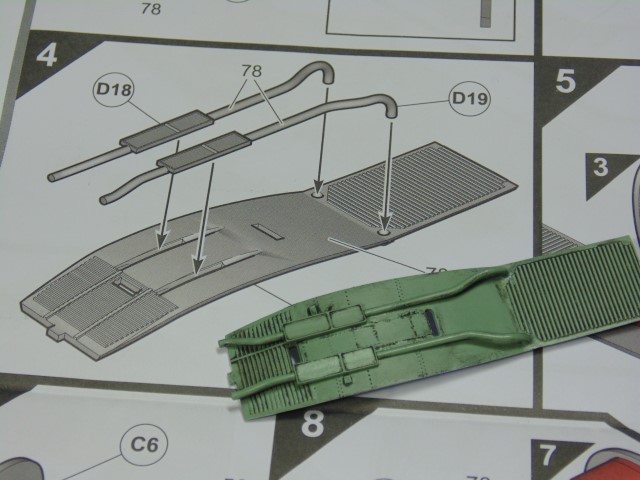

I wanted to know the fit of the fuselage halves to solve the scratch built wiring placement. As it goes, at least for me, one step lead to another which lead to completing another. Thus, in went the wheel bay part. Huge complements to Airfix for the clever engineering on this. Due to my riveting pressures though the part needed help with clamps to make it an ideal fit.

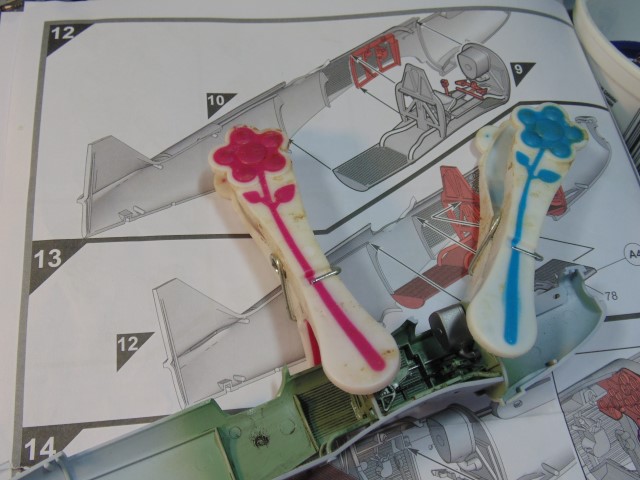

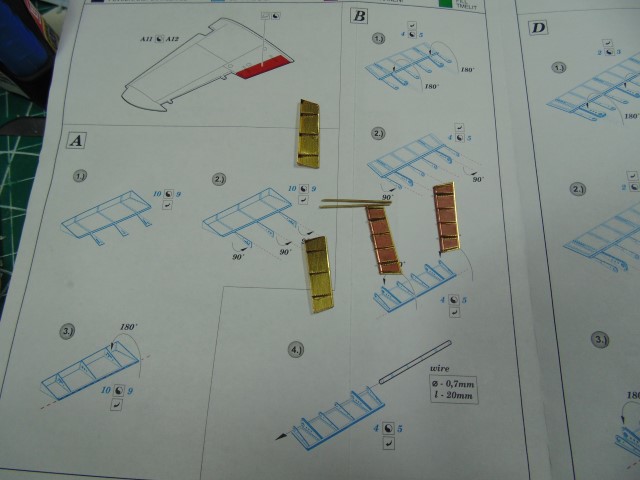

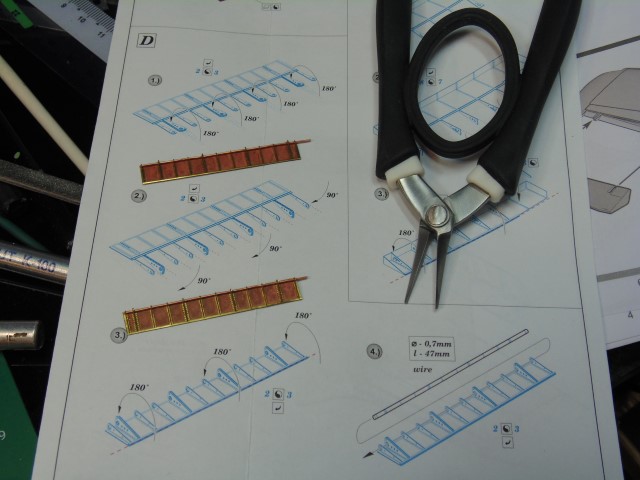

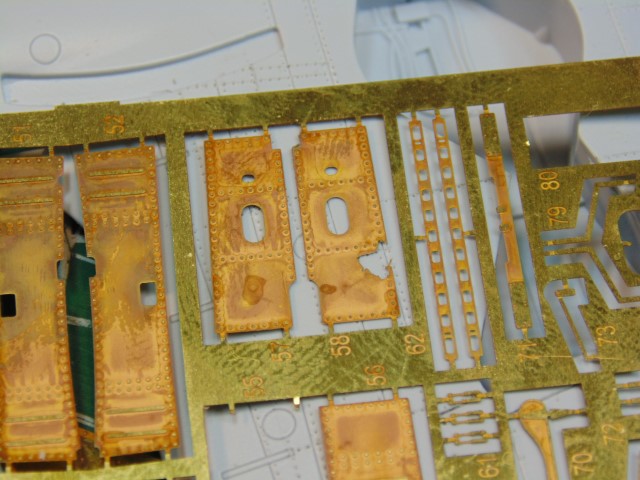

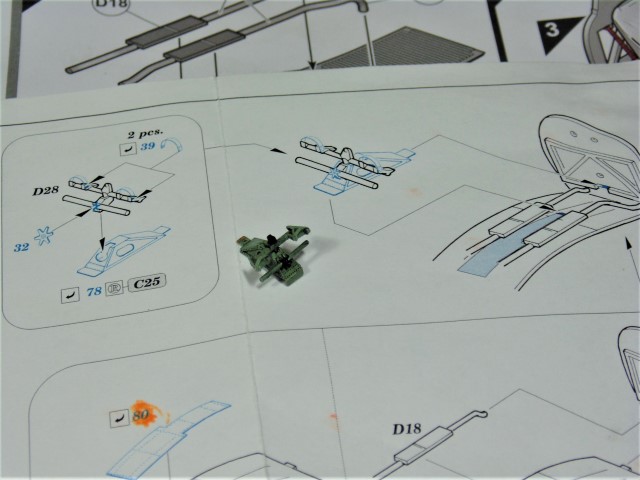

Unfortunately the Eduard PE set has a flaw in 58, but after sending an email and pictures they dispatched a replacement. I’ll install this one for fitment purposes and replace it later. If you need a part…

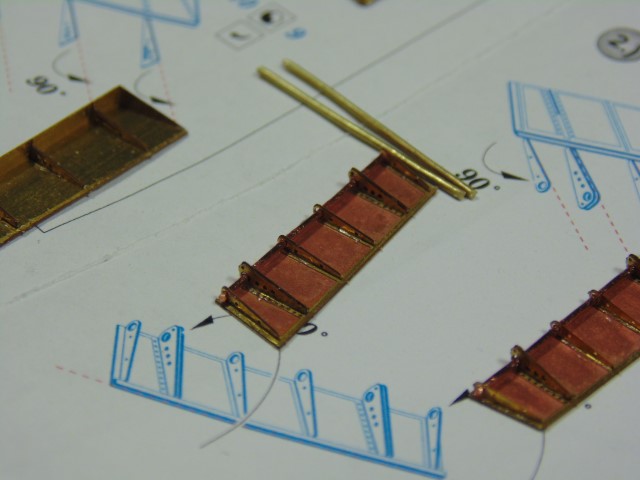

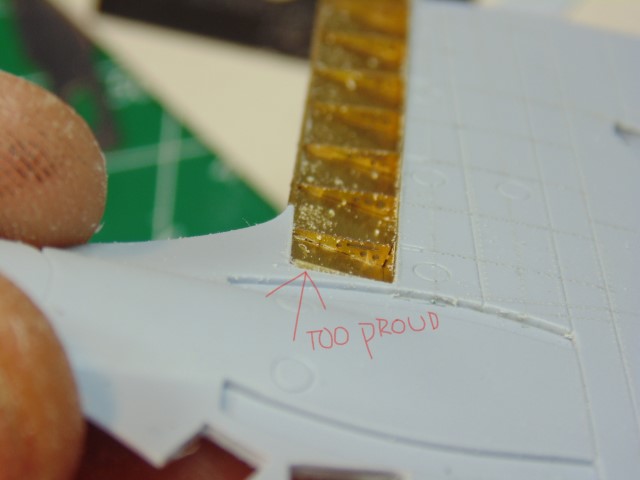

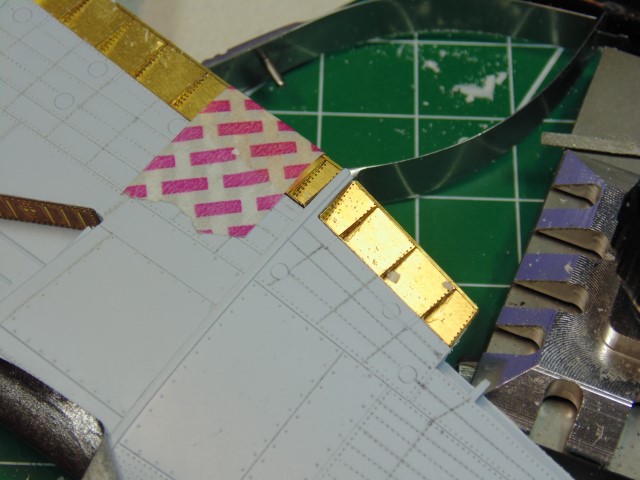

There’s no question that this Eduard set adds a lot of needed detail. You will have to cut the ends off the plastic wires at the inner area of the bays or that shinny PE part will sit proud of the plastic.

First wash done and plenty more to come. Many PE parts have yet to be attached because of the feathering of the wash. They’d be gone for sure otherwise.

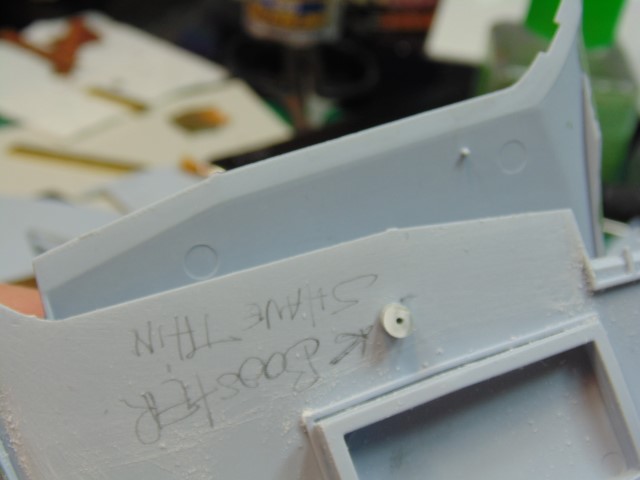

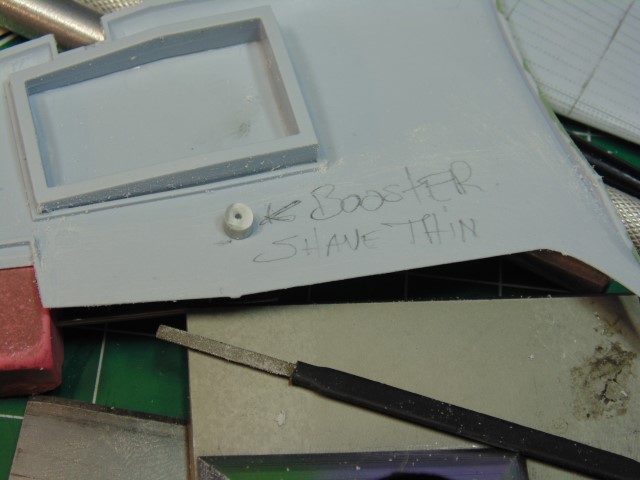

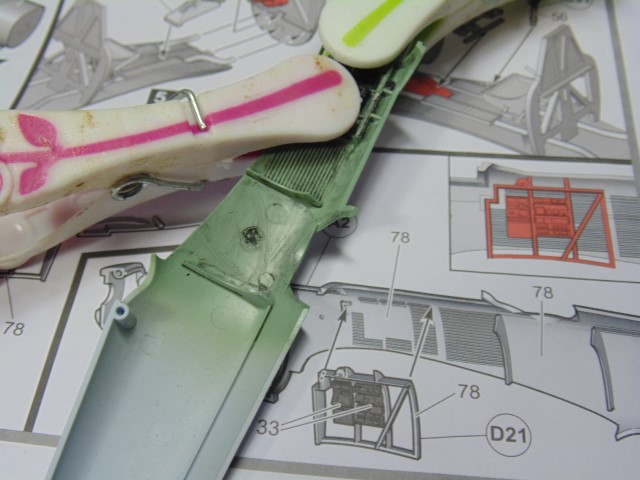

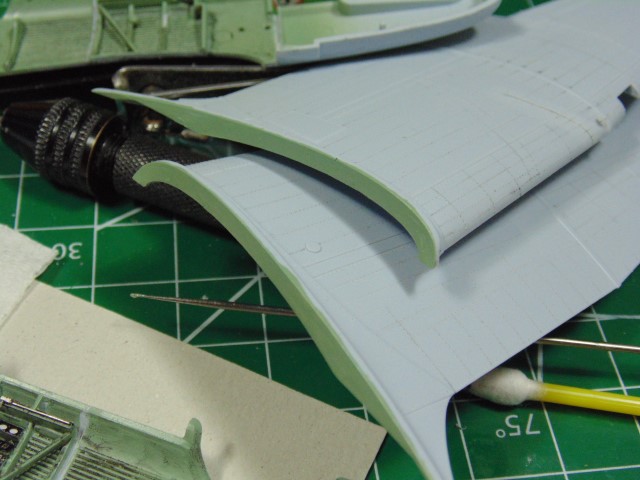

Thinning things out. It’s even thinner than what you see here.

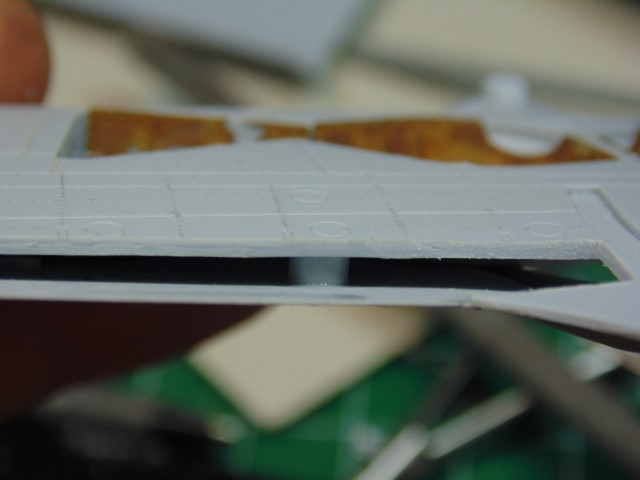

Once again, my riveting work bowed the soft plastic so clamps were doing double duty. If using AK Interactive Real Colors be sure to remove the paint at the joining spots. Super nice fit otherwise!

Rinse and repeat. I used Tamiya white label thick cement for these parts because of the warps and how many places that one part touches the other.

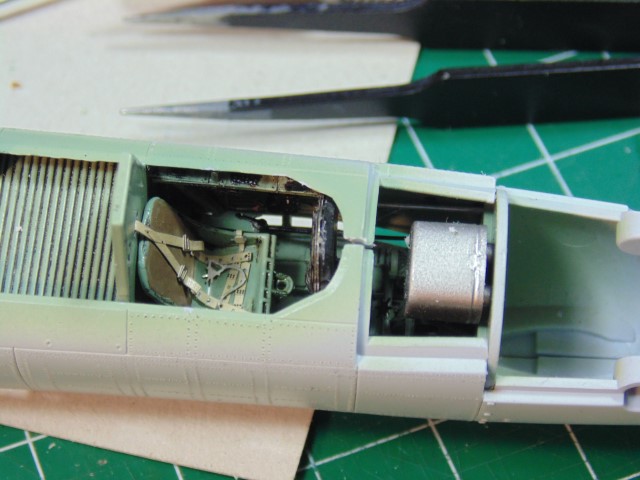

Now before I start getting hate mail Tee Hee, the wash is eventually pulled back quite a bit. It’s in the heavy state now due to handling. When everything is set in an area then I lighten things up by removing much of it, as you’ll see when things come together.

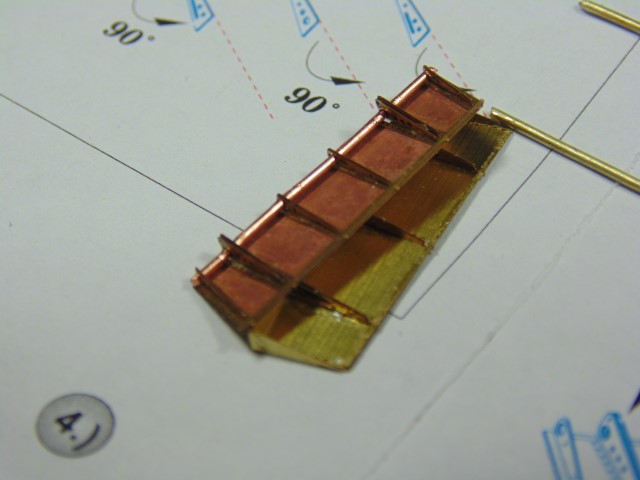

I really like the organic look of these belts. The reason for this is Eduard made them very workable and paint didn’t fling/chip off when bending. I opted to cut the oval hole in the bulkhead instead of snipping the belt and gluing.

After test fitting the floor and bulkheads I knew there would be an issue with bare plastic showing through. You’ll see the same thing, so painting the wing parts is essential to covering this up. Wash to follow.

Don’t think this will be noticeable, but hey it’s a fun part of the build. You’ll need to shave a tiny amount of plastic from the foot falls so the PE part slips in between.

Now I can knock back the wash and complete the extra wiring.

Sure hope this was helpful. Definitely long in the tooth for me, yet I feel it might help speed up your build.

Thanks Everyone.