Understandable, just wanted to set my expectations correctly.

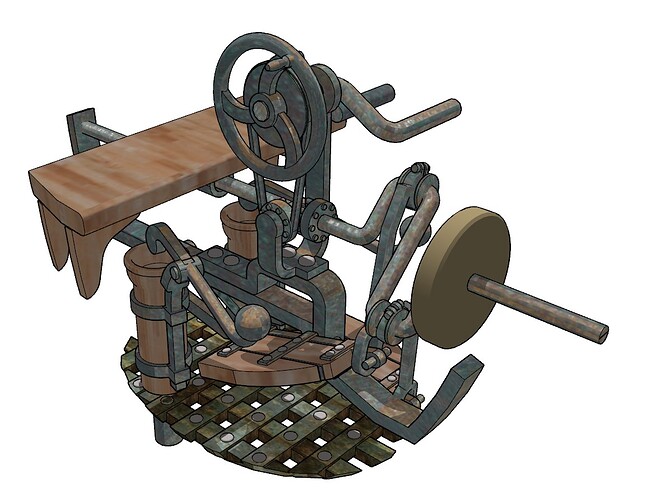

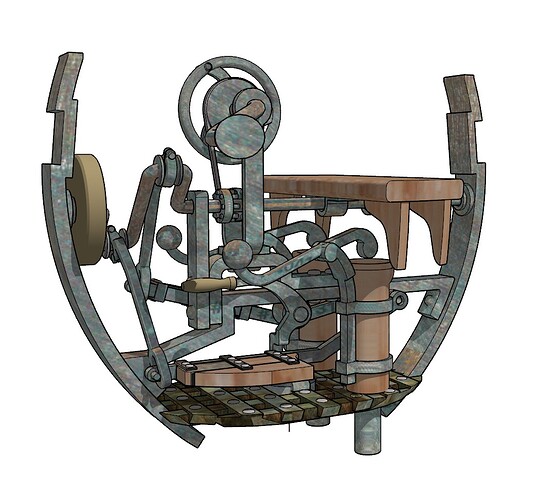

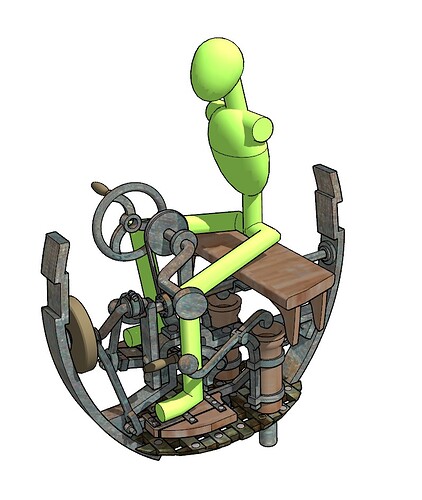

the exercise bike from hell progresses: now with more bilge pumps. (and a bit of colour…)

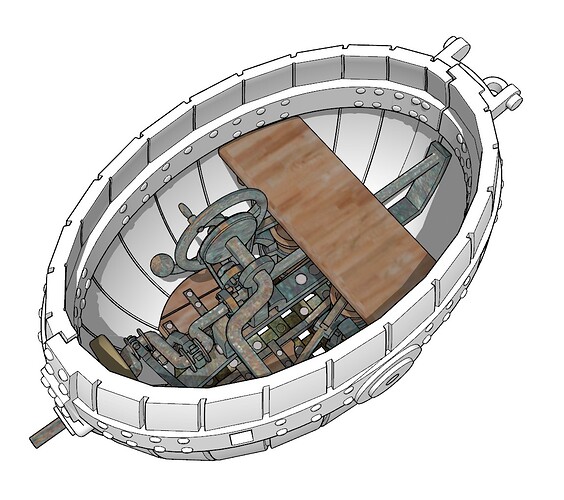

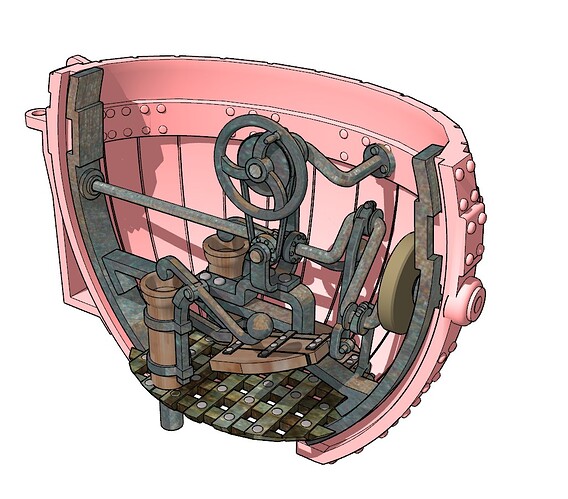

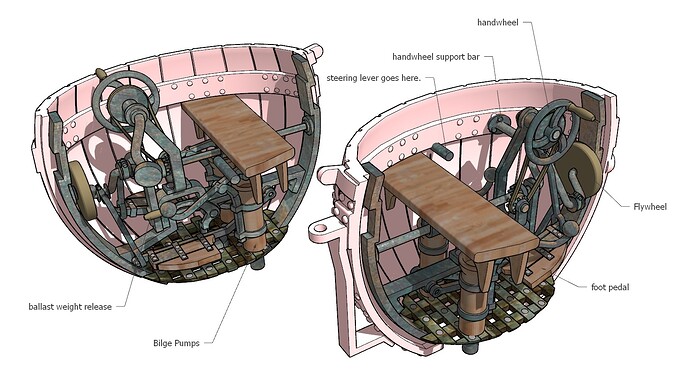

The hope is that most of the internals can be assembled out of the model and inserted later. (the fetching pink colour will be optional)

nothing like designing a ballast release lever before breakfast.

…because submarines need a handbrake.

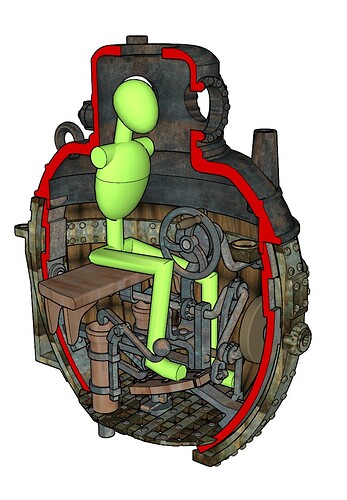

I’m gonna hit the brakes, he’ll fly right by….![]()

![]()

I’ve done a highly detailed figure to help me with the geometries. Pretty close. I’ll need to move the hand wheel forward and up a bit, but the rest seems to be within the realms of reasonable believability.

Fixed! also not immediately apparent in the previous post, I needed to move the seat a tad upwards. Which has let me make the pumps a bit taller.

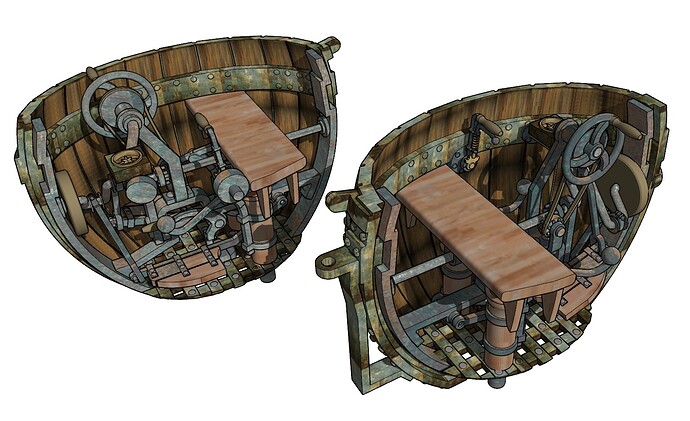

You know that point in the model when you haven’t finished the detailing, but you just wanna paint it?

That.

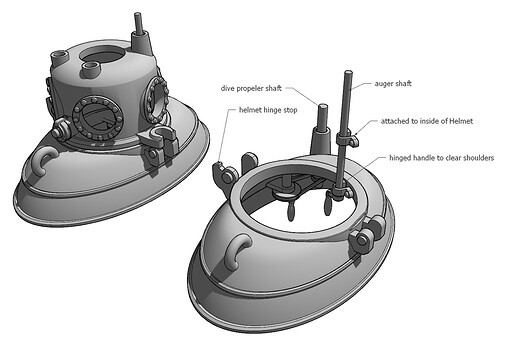

Top end should be simpler, with two operating handles for the diving propeller and Auger, a bellows of some description for pumping air in, and the torpedo release mechanism.

I’m thinking a canteen or two and a pistol to accessorise. oh. and a condensation rag.

and glowing fungus. wonder how they stored that…?

You should make a model of one of the robots from the I Robot movie and let it pedal that submersible.

Similar to Star Wars stormtroopers party crashing Civil War reenactments …

A few more details. So much engineering involved in this to make it work. This bit goes here, but bumps into this bit or interferes with that bit. this bit can’t swing past that. crew wouldn’t be able to reach that thingy. There have also been sacrifices made to aesthetics ('That looks cooler that way…), and buildability (that part will be too thin, or need a better connection).

Still, having fun.

Also starting to put serious thought into producing this as a kit, as far as ordering a more suitable printer for the larger sections. Like an Elegoo saturn or Mono X. (the fiddly, really fine details will still be printed on the Form 3, if there’s a noticeable difference…)

Craig just keep on doing what you’re doing because your renderings blow my mind (PS can you run me off a 1:12 Monitor & Merrimac?)

With or without interior?

Okay. made some decisions Things have been purchased…

…and reasonably post proof and satchel friendly packaging designed…

another week or two and we should have a solid price estimate. There will be a 1:35 scale kit (no interior), and a 1:16 kit with all of the fixin’s.

Really I doubt I could afford the exterior versions in 1:72. Back in the real world good on you/your commitment, I’m imagining submerging the Turtle in a resin block of water with one side clear to show off the interior

well, I do have a 1/16 Hunley planned…

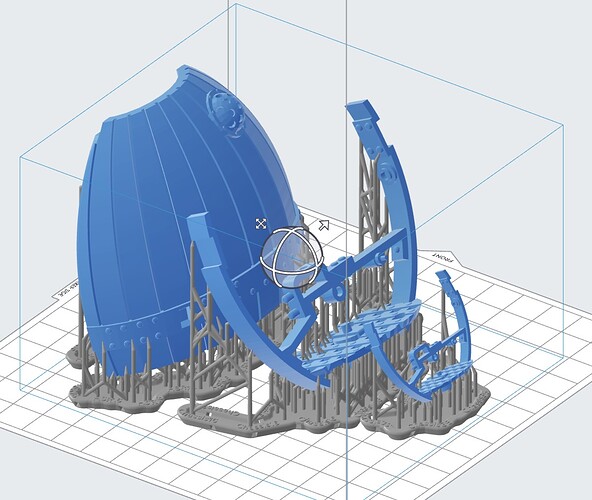

Testing, Testing…

One of the main reasons I need the second printer is that it should be quicker. The Form 3 is a beautiful machine, but it ain’t fast and it’s very expensive to run.

This, for example, is 12 hour print. Note also I’m testing a 1/35 interior, but I really think it would be too fragile and frustrating for most, especially those inexperienced with 3D printing, to remove from supports and clean up. There would be breaking and snapping and unhappy e-mails.

So that 1:35 test would be around 3 to 4 cms high? My railway mate bought a printer from Aldi a few years ago, don’t know the brand but after it failed (first use) and was repaired in Melbourne it’s worked perfectly ever since, although I suspect his would also take 12 hours (or more) to do that.

Indeed, breaking & snapping emails too. Excuse my general ignorance but if that test would be too fragile, would you increase or decrease the scale?

I’m thinking scaling the 1:35 up to 1:32, which would make a tiny difference, and be more in keeping with traditional boat scales. I can thicken some of the parts to what I would consider over scale to make it work. Model manufacturers do that all the time.

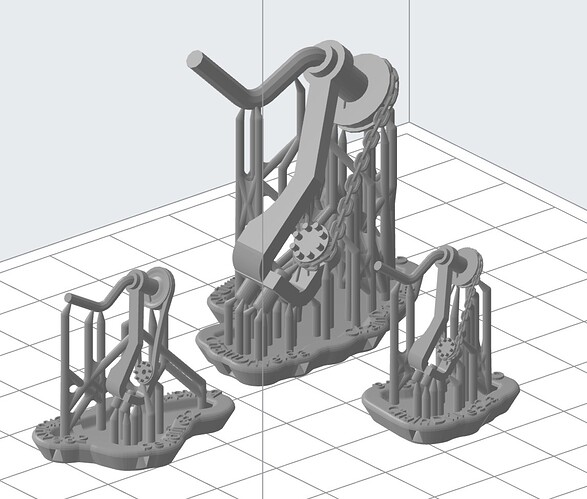

Example: The assembly on the left (1:32) would be WAY easier to remove from the support material than either of the (1:32 or 1:16) chain drives on the right. 3D print resin is quite brittle.

actually a poor example. I think I’m going to include short length of actual chain for this.

Anyhoo, point being sometimes a complex tiny part can be overwhelmed by support material to the point that it becomes nigh on impossible to remove without damage.

OK that makes sense – although from this nutty punter’s viewpoint, whether wandering around my LHS (HobbyCo Sydney) or on-line supplier (BNA), for me to excavate my wallet it would need to be 1:16 scale injection-moulded plastic. I realise that’s easier said than done but from a commercial/viable angle it’s likely the difference between a sale & no-sale from me - I hope for your sake I’m in a minority

Well, new printer should help keep the price down a bit.

if you are not sure about cleaning up 3D printed parts it’s actually pretty easy (tiny fragile parts aside…)

…five hours and 26 minutes to go…