Going to challenge my ability to walk and chew gum at the same time by trying to simultaneously complete a build and build log of Tamiya’s 1/35 M3 Stuart.

I’ve started build logs before, but never seemed to get to the far end for one reason or another. But this should be a nice, straightforward build so fingers crossed (Are you sure about that? More on this later).

If you are interested in some of the background for this build, read on. Otherwise, just skip down to the photos where the good stuff begins.

One of the first armor builds I can remember from my youth was this same kit I got from my parents as a Christmas or birthday present, and recently I had been feeling somewhat nostalgic about it. As it happened, not long ago I was in second-hand model store I just discovered in a back alley in Tokyo and I found this kit. To my surprise and delight, they also had a set of Modelkasten workable tracks. Yea, me! The irony is that the box for the tracks is nearly as big as the box for the kit–that should have been a warning.

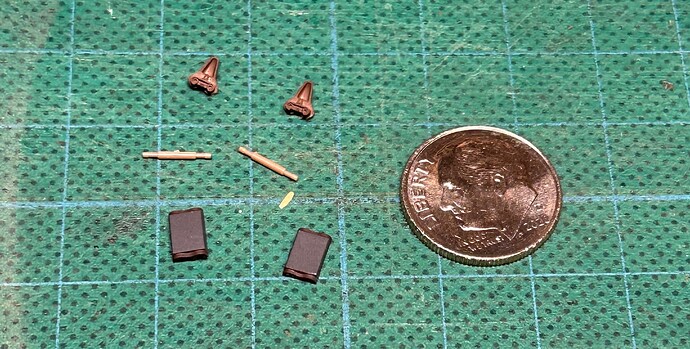

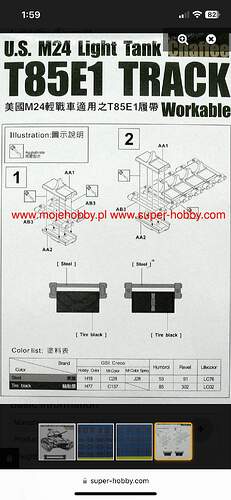

The part count for the kit appears to be around 150–typical Tamiya simplicity–whereas the tracks require 134 links (both sides) with six microscopic parts per link for a whopping 804 pieces! What have I gotten myself into?

I started the process of painting the tracks while I was still working on my AS42 Sahariana. track pads and guide horns were primed and airbrushed, then the metal ends of the pads finished with a hairy stick.

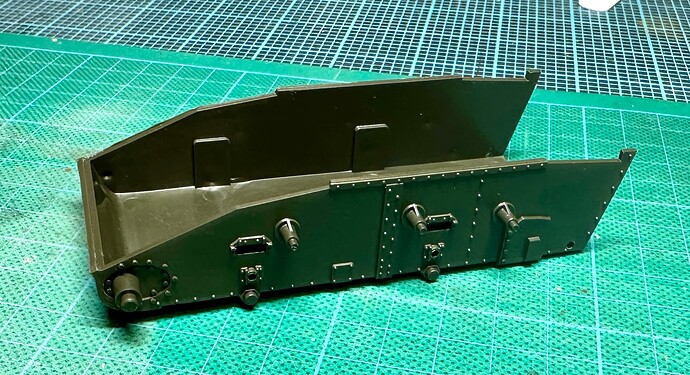

The Sahariana finished, it’s time to begin work in earnest. The hull tub has the drive sprocket axles and track support roller stanchions molded on.

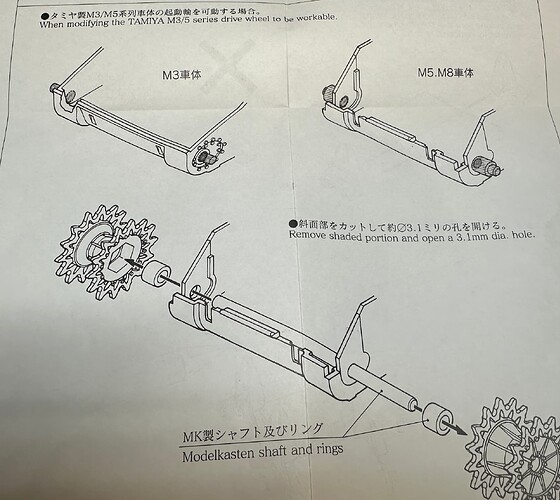

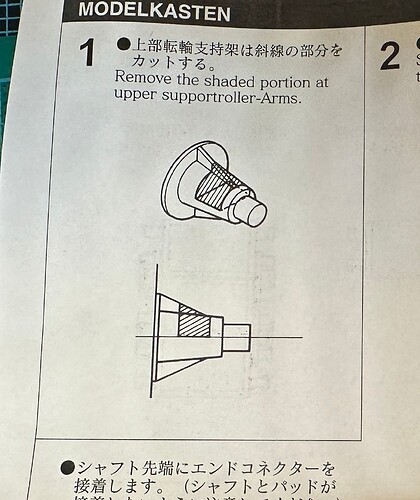

Unfortunately, Modelkasten doesn’t like those so some surgery is required.

My first consideration is whether I want to open up the holes for the sprocket axle slightly along the horizontal access so I can allow some play in the action. That way I can get the tension on the tracks right. Still thinking through how to spring load the axle. Don’t want to use rubber bands that will eventually harden and crumble. Stay tuned to see what solution I come up with.

My next concern is that removing that much material from the stanchions is going to leave them weak and prone to breakage. My plan is to first drill them out and insert brass rod to replace the roller axle. Have yet to figure out yet how to get the necessary precision since I had to leave both my drill presses in Rhode Island when we moved. I have some ideas, but experimentation will be required before I do anything irreversible.

To the bat-bench!

![]()