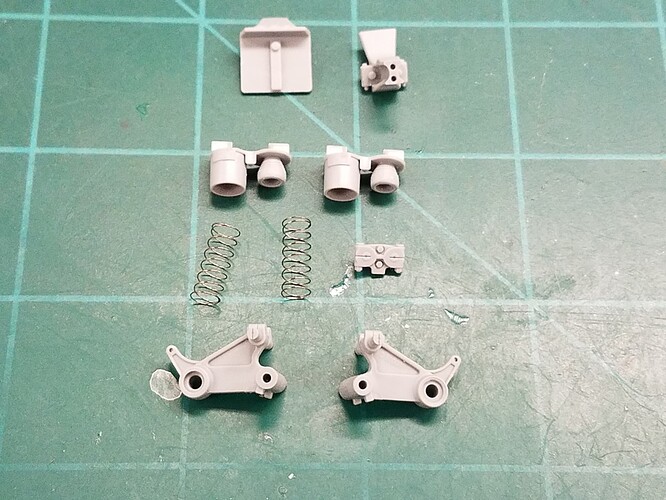

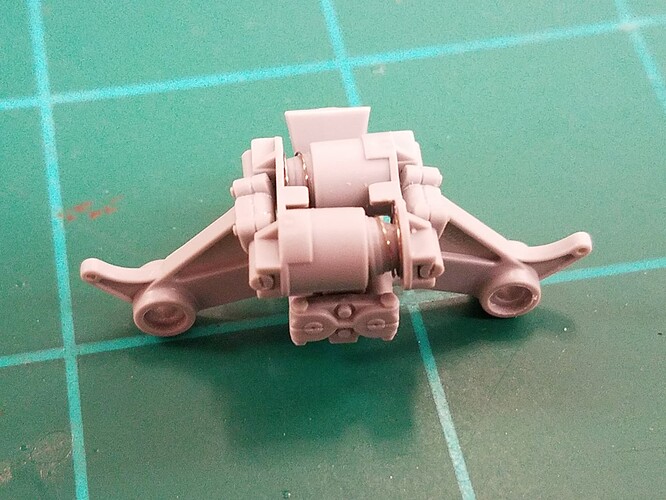

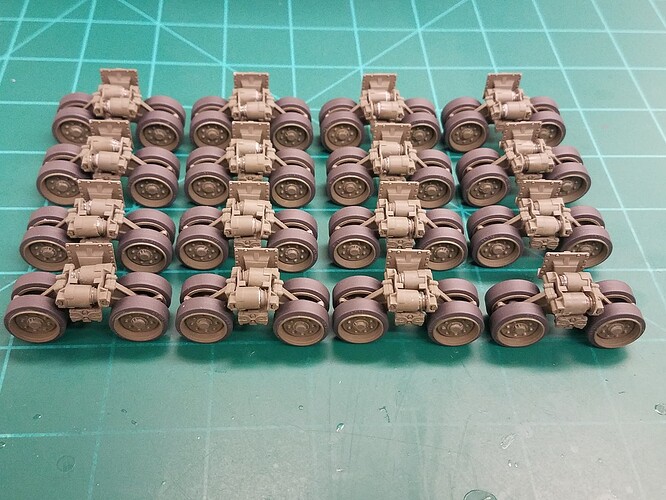

OK, this is my first time posting a build log so I hope I’m doing this right. This is the Dragon “Smart Kit” #6750 issued in 2012. I bought mine then for about $70. It has a ton of pieces, anywhere from 700 to 1700 depending on whether you count the number that are not used, probably close to half of them. The vast majority of parts are for the suspension as you can imagine as there are 4 runs of track.

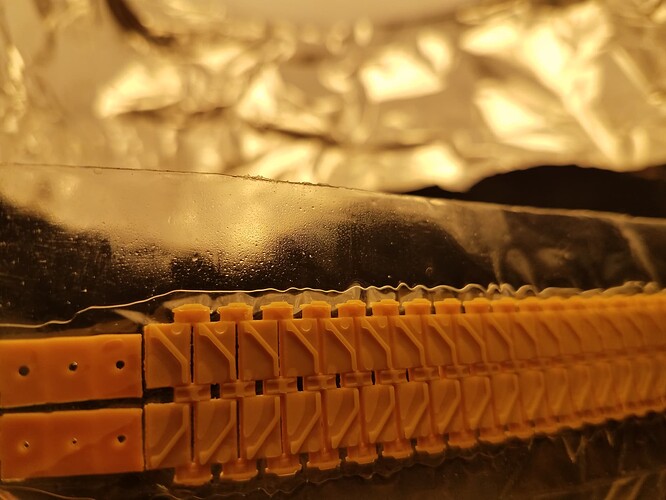

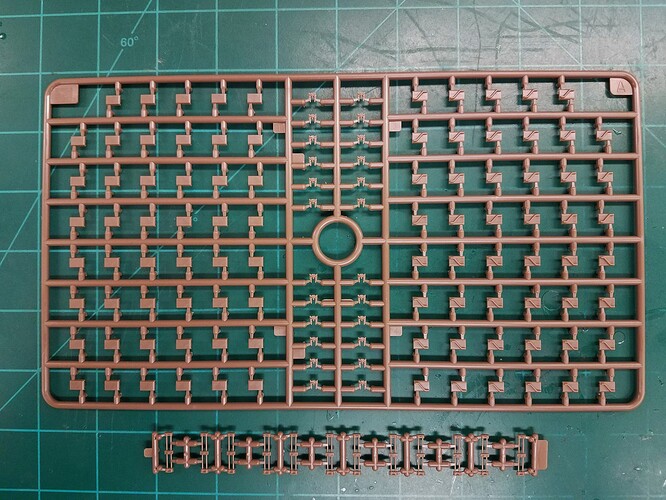

And speaking of tracks, let’s get that issue out of the way up front. The 8 track sections are rubber band type DS and mine were worthless when I opened the shrink wrapped box after almost 10 years. They had started to liquefy in their sealed plastic wrapper and the DS plastic itself was very brittle (note the broken tabs).

The goo had started to leak through the wrapper but, fortunately only got on the parts bags directly under it and didn’t penetrate those. Word to the wise: if you have this kit you’d best open it and see what you have.

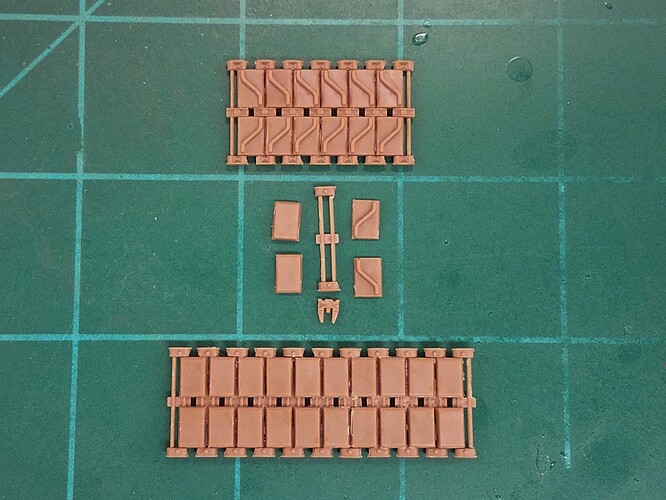

So, after some help from a couple Forum members (thanks again guys) I bought 3 sets of Bronco T80E1 tracks for $70 as replacements. While they claim to be “movable’ I will glue them together as link-length because . . . . . I plan to build the tank in travel mode with the outside tracks and sponsons being towed. Trying to keep them movable will be a headache I don’t need. You’ll need three kits to get enough links for 4 track runs on this beast.

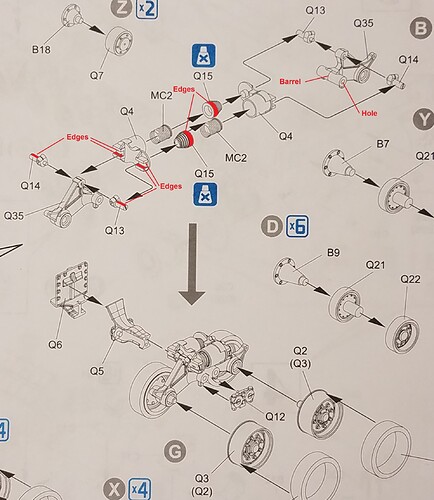

Since there are already a bunch of in-box reviews out there I’ll skip all that and get right to the build. You can check them out to see what all is in there if you are interested. As typical of Dragon, there are mis-numbered parts, vague part orientations, unnecessary holes drilled, and some out-of-sequence construction steps. I made copies of the instructions to mark up as I go along just to keep things straight.

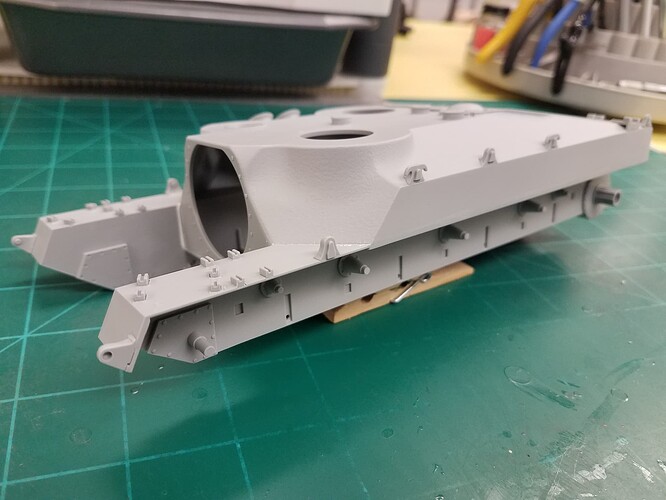

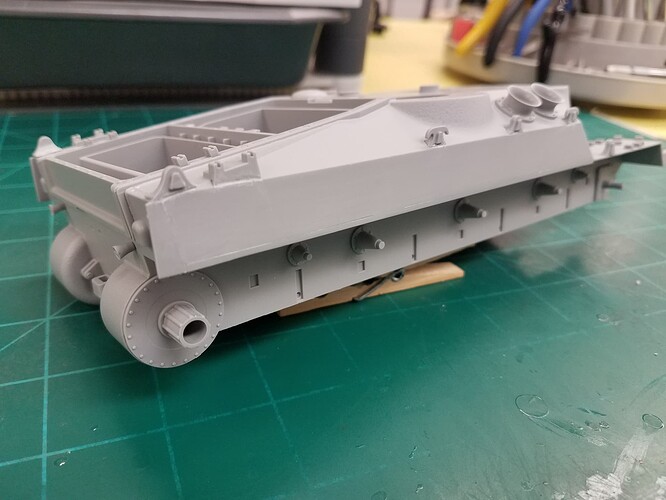

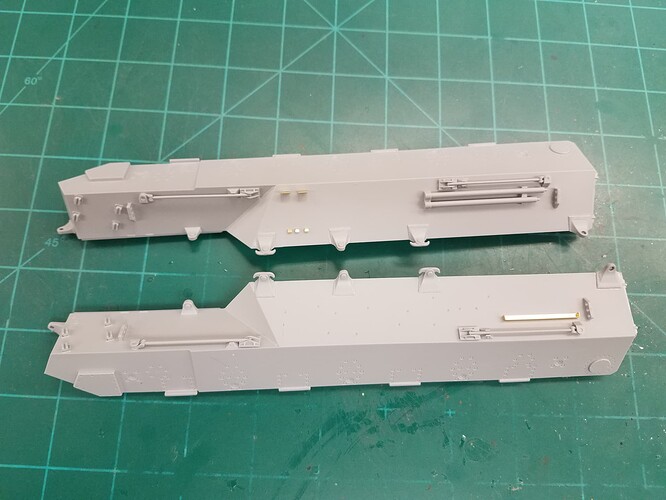

Since the replacement tracks are still a week away I’ll start building the hull and sponsons. The hull fit is fairly good but some of the lifting hooks need some trimming to sit correctly. I am leaving the pioneer tools off till later.

The sponsons are not too difficult but some parts placement is vague.

More to follow.