For those who are interested in the history of Blackhawk Tools (or any other tools) this web site has plenty of information on Blackhawk. I learned before they standardized 1/4”, 1/2”, 3/4” drives there were other sizes too like 7/16”!

I follow your progress.

very accurate job.

I was hoping to have my test shots delivered today but No Joy, so I have continued to do more research and refine the Blackhawk toolbox.

Thanks to the Garage Journal I have found more information in just a few days than the previous years I having been trying scrounge info on the elusive tool chest.

Here is just some of the info that this enthusiast has gathered in helping him restore his box.

https://www.garagejournal.com/forum/threads/my-small-but-growing-1-4-drive-socket-set-collection.405698/page-39

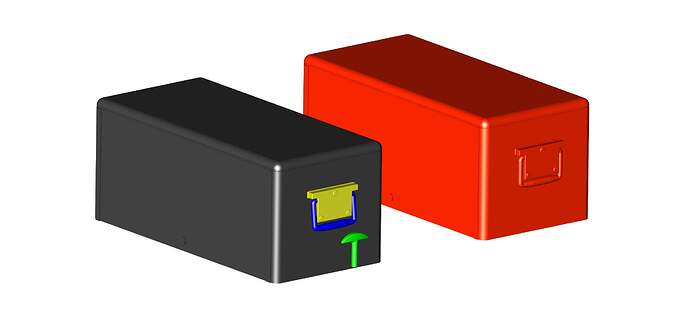

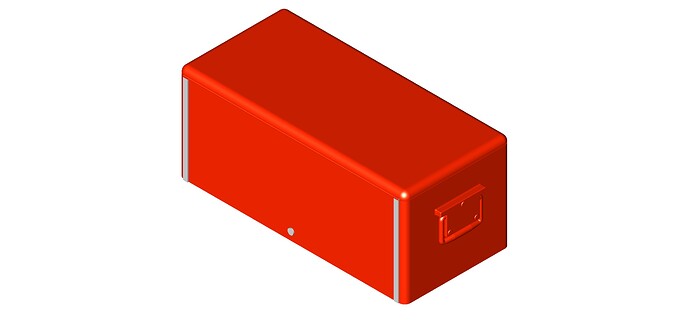

The Blackhawk box is a 100W and was an off the shelf box that was red in color but overpainted black for the military and had an FSN 41-W-2613-500 which included the 100 piece tool kit as well.

Blackhawk did not make the box itself but like most tool manufactures outsourced it to a company that specialized in making sheetmetal goods in this case Langenau out of Cleveland, OH (and are still in business).

Here is a better picture of the Blackhawk in its original color!

It’s a rather attractive looking box with the rounded corners, I can see who they are popular with collectors.

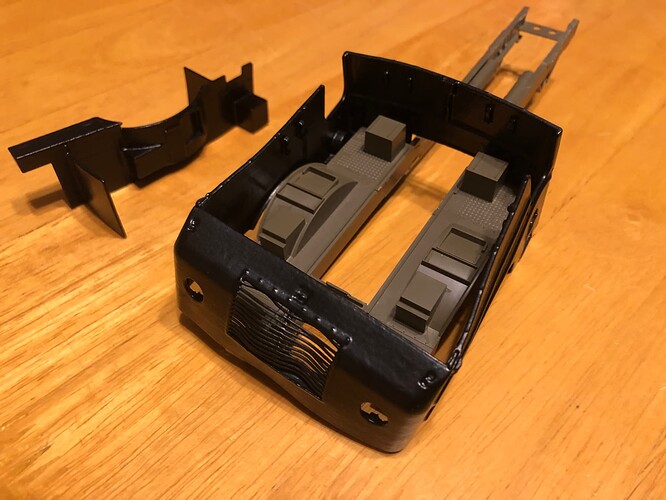

Well I had my first setback! I ordered a test shot from Shapeways in what I thought was a black nylon but turned out to be some sort of rubber like material!

No doubt you are doing a great job, however I think nowadays there are much better options for 3D printing than Shapeways, probably in your own town or not far away…

So it opened only from the top? I’ve seen some red boxes that opened from the top and front.

Thanks Dan

+1

It shouldn’t be too hard to find someone local doing 3D printing or even collaborate with another modeler who is doing 3D printing. Even living in a sort of scale modeling backwater we have several local 3D print-on-demand providers, ranging from a local computer shop to a local gaming shop.

An option might be to look up local “Maker Spaces” or to find a local school that has a strong STEM program. Often both of those options can lead to individuals who are really engaged in 3D printing.

Yea, it opens from the top but there is a panel on the front that is hinged to the top lid that reveals the drawers.

Thanks

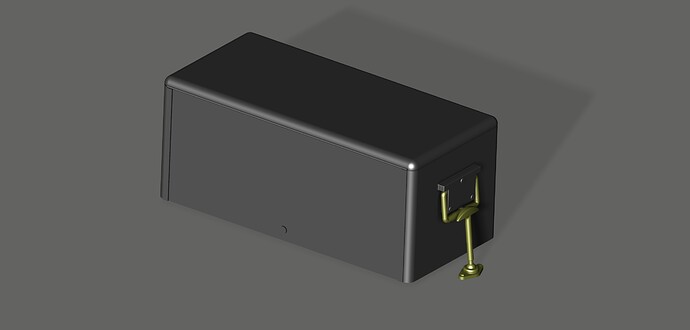

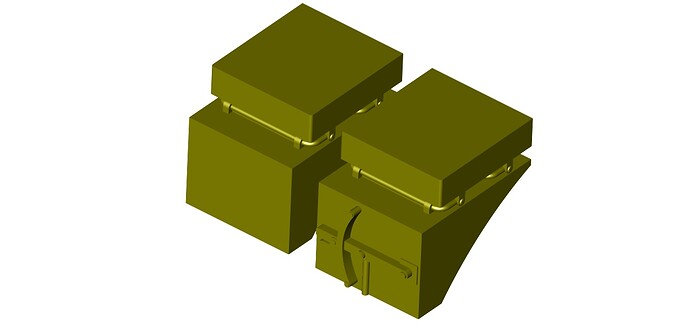

I finished up the Blackhawk Tool Chest and I will offer this on my Etsy Store as a separate item as well as part of the Soft Cab conversion set. It was interesting doing research on the Blackhawk just how many different tool manufactures the U.S. Military relied on during WWII to meet their demands. Virtually every vehicle in the Army alone had their own tool kit and then compound that by the depots, Army Air Corp, the Navy, etc. and you realize just how big of a task it was to supply the needs of the U.S. Military and its Allies during WWII!

Love to buy this but it looks like I need a 3D printer?

Dan

Correct, the handles and hold downs are probably too small for Shapeways to print.

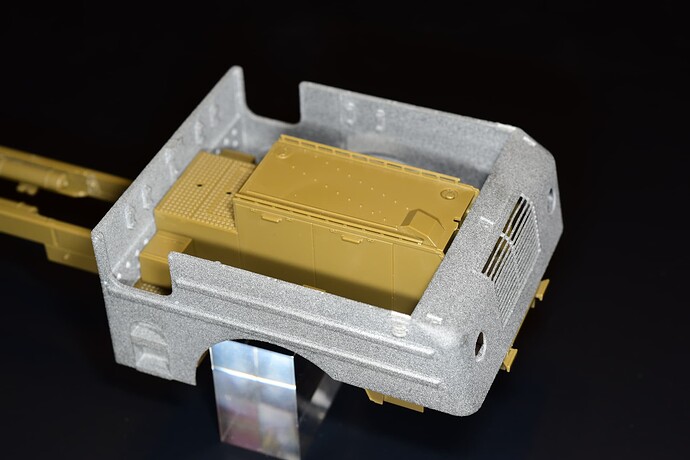

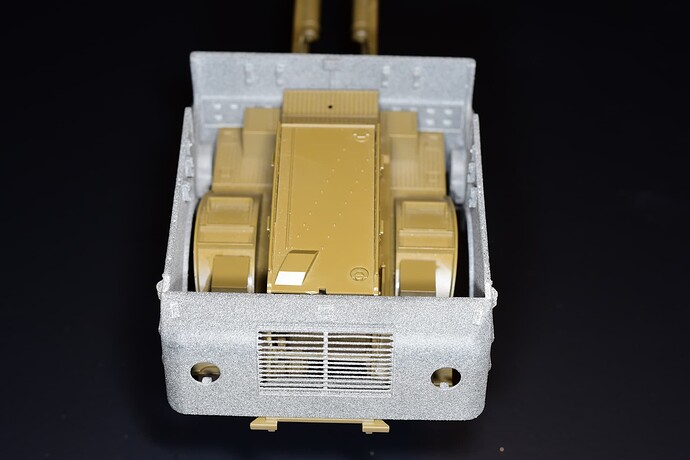

I got my Dragon Wagon soft cab test shot today. The material it is printed in is not designed for detail work, the process is a nylon powder that sintered by a laser to build up a part. The printed part comes out very pebbley, like it is made out of stone.

Overall I’m satisfied with the fit. The modeler will have to make some small modifications to the plastic parts, namely cutting off the existing floorboards and maybe trimming the motor housing where it will meet the new windshield.

With the resin 3D printers that most modelers have, these parts should come out very nice!

I had a hiatus in October with some other things including creating items for the new 1/16 scale Takom Sherman but I am getting back into the groove for the Dragon Wagon.

Some parts appear to be simple to design but then once you dig down they can be a little tricky!

Case in point, the MG Ring. The three mounts appear to be 120º apart but in fact they form scalene triangle. The ring was more commonly used on trucks and the mounts had to be adapted to a variety of different cabs hence the odd spacing around the ring.

I think the legs were something like 38" x 42" x 39". On top of that I had to center this scalene triangle to the ring and I was bumping up against my Jimmy Carter era High School geometry acumen!

After careful examination, I don’t think I will need to do complete floors which not only save the modeler much surgery to the kit but to me as well. The fender arches will have their outer edge trimmed back 1.5 mm and small outer floor plates installed. I have also created better seat pedestals including the control for the forward winch!

Well it is finally done and up on Etsy. I completed the instruction sheet (I’ll probably make changes later on to pretty it up a bit more). I’m going to take a break and then work on the M15A1 trailer. The good news is that it’s already done, I just have to make changes to certain parts to make them easier for modelers to resin print them at home. https://www.etsy.com/listing/1342764749/135-scale-m26a1-dragon-wagon-soft-cab?click_key=0c6d1c440ab86e51b17a8c215f086c88b155bb6e%3A1342764749&click_sum=0e40147b&ref=shop_home_active_1

After I completed my instruction sheet I could not help but to think back to one of my favorite Black Adder Episodes (I’m one of fifteen fans in North America!), because I neglected a few parts. https://youtu.be/PuDquo76490

The brace for the winch control shield should be obvious but the two handles in this picture between the light guard and the Blackhawk Tool Chest hold-downs are the handles for inside the windshield frame that lock the windows.