Figured it’s about time I got a blog going on this kit. I was hesitant to start one as it’s my first ship and much could go wrong, but it’s been a few months and I’m nearing the end with no build stopping disasters so I think it’s safe to start from the top.

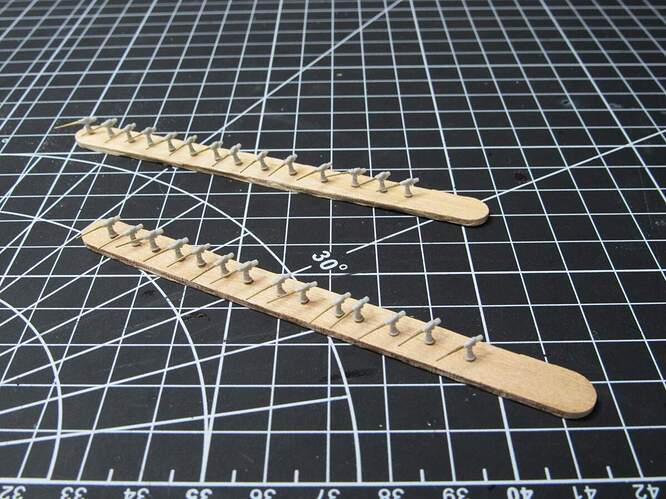

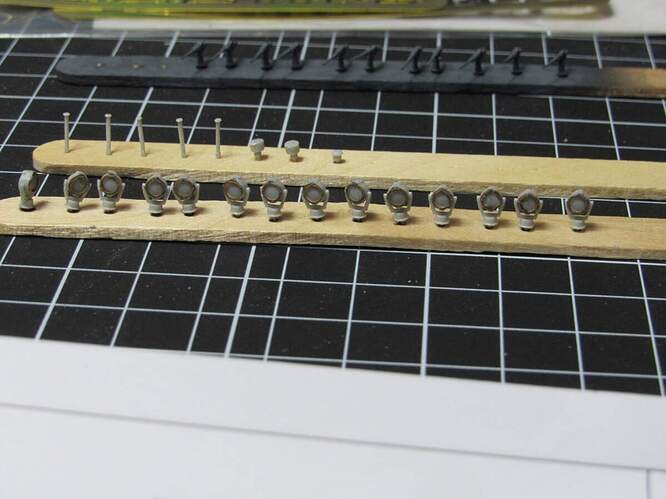

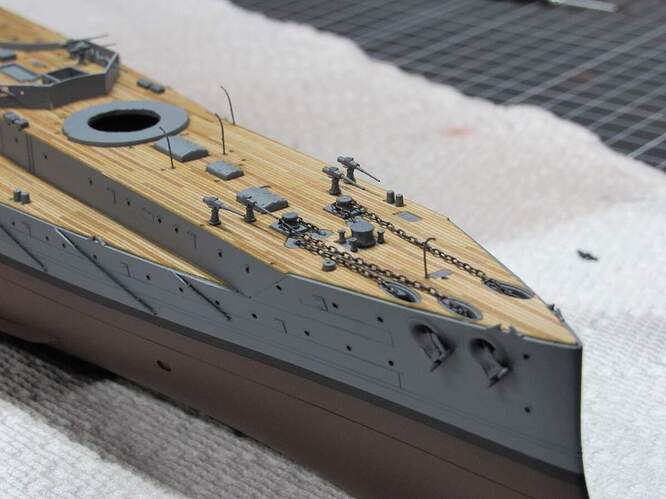

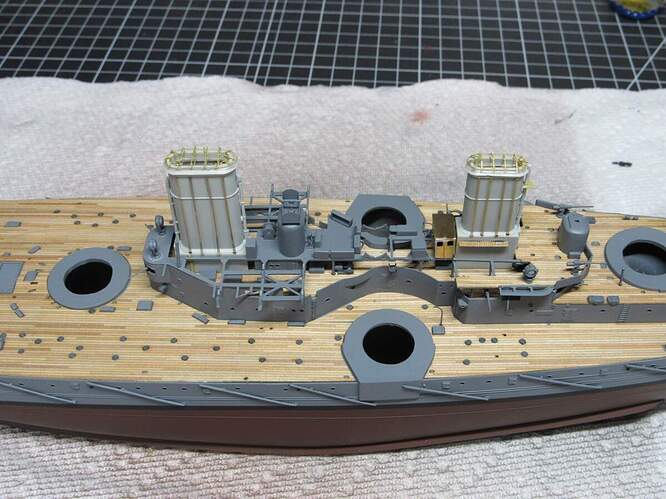

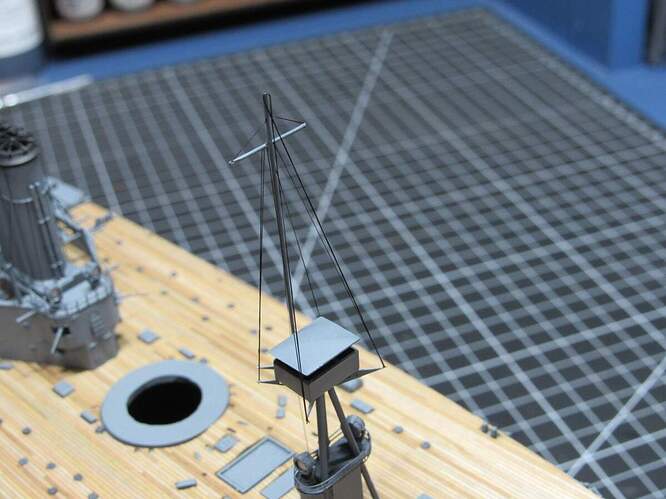

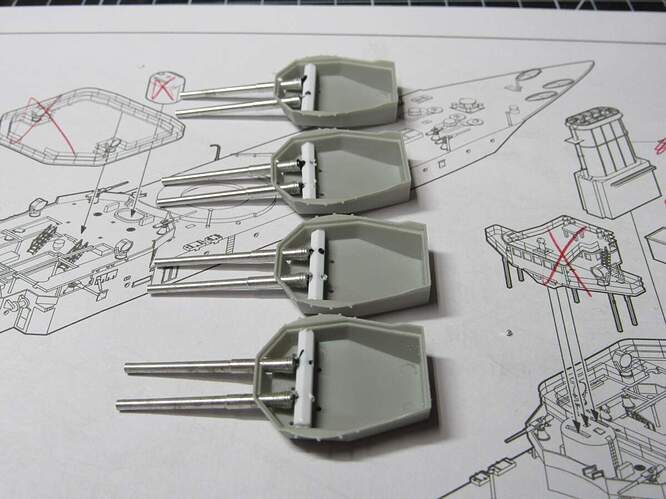

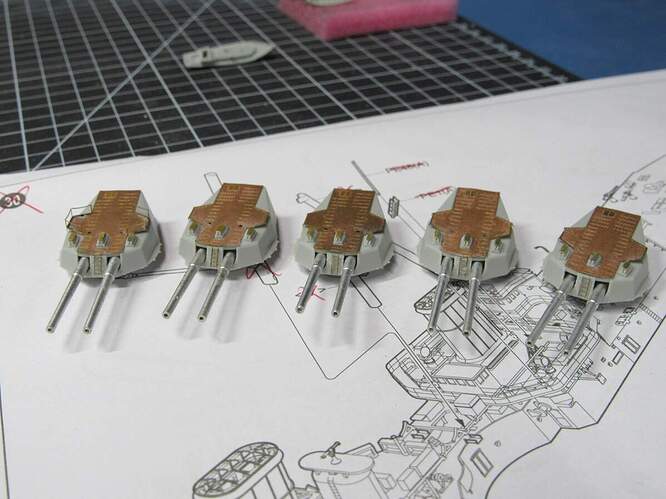

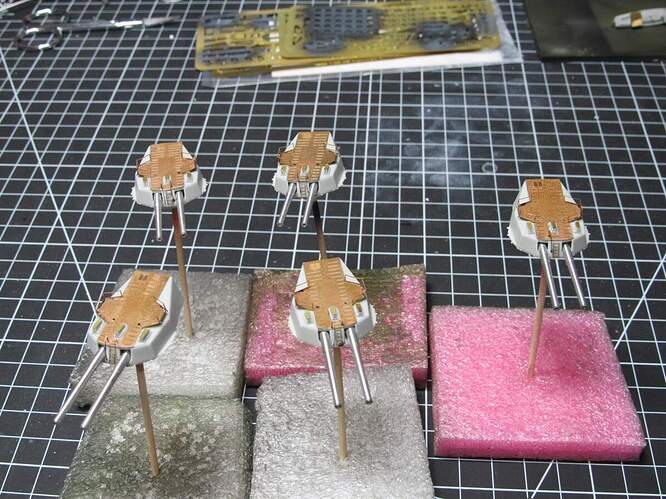

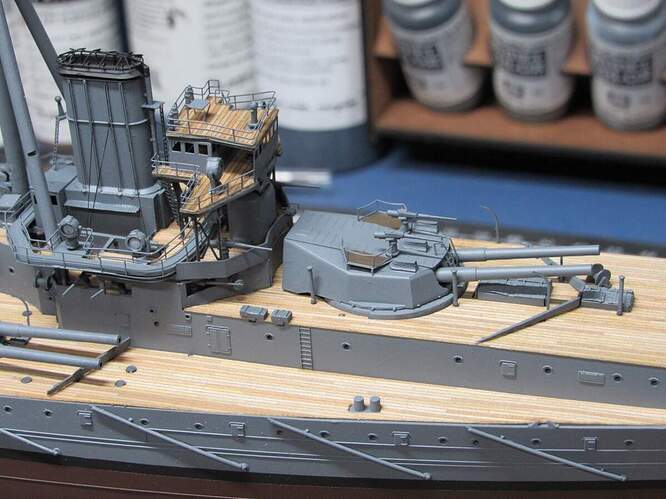

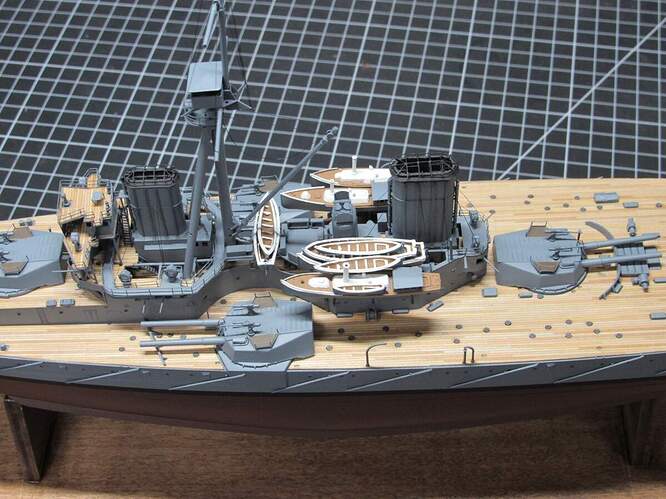

I’ve been wanting to build a ship for a long time, and the revolutionary Dreadnought is a ship I always liked, so what better place to start. I also figured go big or go home, so along with the Trumpeter base kit, I got both of Eduard’s PE sets (railings and general details), Aber’s barrels, and a wood deck from ScaleDecks.

Naturally the build started with the hull. No issues there, just some sanding and filling along the bottom seam as expected. One thing I don’t like about the kit is the instructions, to minimize the amount of painting I wanted to get the hull detailed up in one go, which requires combing through the entire instruction booklet to make sure you don’t miss any parts (I missed the PE ‘Dreadnought’ name on the sides).

For the boot top masking I used a pencil through a block of wood to mark a uniform line around the hull. Then it was just careful masking and painting.

Next was installing the wood deck, and the first hiccup.

It’s out of scale along the fore-aft direction. A quick email to ScaleDecks followed by a quick response that there was a bad batch of these and they’ll send out a replacement. This is where the build stayed for a couple months while I got distracted by other kits.

Eventually I got my replacement and finished up the other distractions. The upper deck went down fine, but when it came to the main deck I had more issues.

I thought I got another lemon, and figured the kit would be total loss without buying another deck. Not wanting to invest more I shelved it for a couple weeks. But it eventually dawned on me that the main deck piece was supposed to go on before the upper/fore deck was attached to the hull, as part of it would slip under the structure. Since I had already cut the port and starboard ‘wings’ from the main deck, I figured some more surgery wouldn’t hurt, and surprisingly got it to work.

Now time to start filling in the details.