The first thing you have to conceptualize is that EVERY SINGLE injection molded part has imperfections that must be addressed before it will fit as the kit designer intended.

A lot of these imperfections are not as obvious as others, so you must learn to study each part to identify these imperfections and then decide how to address them. This is a slide show that a friend in our local modeling club put together when we were discussing this basic modeling skill.

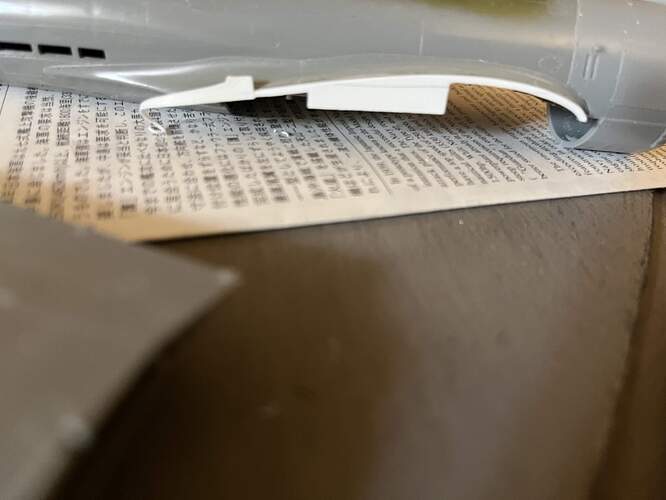

Basic Modeling" Mold Seam Profiles

Once you have identified the molding imperfections, you will usually use the same basic tools and techniques to address them:

Cutting / carving using the hobby knife to trim away the imperfection. Useful for large, heavy mold seams or excessive draft features.

Scraping using the edge of the blade of the knife to remove minor seams or light imperfections. Note that the closer to the tip of the blade you use the more control you will have, but the slower the removal will be.

Filing using needle / jewelry files to level large imperfections or to remove or mitigate tooling marks from the cutting or scraping process.

Sanding using various grits (600, 400, 320, 280, 120 etc.) to smooth out light imperfections or to smooth out tooling marks from the earlier steps.

Buffing using 4x0 steel wool or a pot scrubbing pad (which can be very aggressive - be careful!) as the final smoothing effort to perfect the surface finish of the part in the areas where the earlier tooling steps were taken.

Test-fitting / dry-fitting to check your work. Sometimes you will find that the molded-on alignment features (usually pins and holes) do, in fact, hold the parts in the correct alignment with each other. If you find that the parts are not in alignment or that the pins and holes don’t match in size, you should fix these problems (drill the holes larger or cut away the pins).

There are, of course, more things that you can do, but these are the very basics. As a matter of routine, I “clean up” the sprue attachment points and 100% of the mold seams around the edges of each and every part. In my experience, it takes more time and causes more trouble to try to predict which mold seams can be left assuming that they can’t bee seen or won’t interfere with correct alignment than the time and effort to simply address the issue 100% of the time for each and every part.