We’re back. The ride to Philly was splendid with gorgeous weather both days. The ride home was the polar opposite with clouds, rain, sleet, snow and wind. All that was missing was hail. It took a bit longer, but the car ran perfectly and we arrived unscathed. My wife decided at the last minute that she was not so inteseted in visiting a battleship so I went alone.

With the main condenser and low pressure turbine in pretty good order, I started working on the high pressure turbine and the small impulse turbine that drives the main condensate pump. John Miano got me good drawings of both, but there were stil many ambiguities that I couldn’t resolve. Those concerned with the pump engine weren’t show stoppers, but the questions surrounding the hp turbine were crucial. The most imoort of these was how the machine is supported. I couldn’t find the answer in the drawings. I had to visit the ship again.

Last week, Ryan Syzmanski and I spent and hour and half in the un-refurbished engine room #3 and I focused on three areas: HP details and foundation; Main steam piping runs; and the main condensate pump drive.

Boy! Am I glad I did this. I was completely wrong in my thinking and had two triangular brackets installed on the output end of the main condenser that are actually two of the four that support the startboard side of the main reduction gear, the apparatus that sits BEHIND the condenser in this view. There are also triangular brackets surrounding the MRG on the other three sides. I am assuming that even with the properller shaft’s thrust bearing quite a ways astern from the engine rooms, there is still thrust that must be directed into the ship’s structure to push the ship forward and these massive supports are part of that system.

The propeller shaft from the engine room forward of this one has a bearing that sits on top of the curved support that’s welded to the triangular supports. Thse supports captivate the MRG and it ain’t goi’n anywhere! Engine room #3 has shafts running through the lower level from engine rooms 1 & 2. Engine room #4 has three shafts spinning through it.

Just imagine, for a moment, the noise in these spaces when the ship was crusing at flank speed. I counted six steam turbines of various sizes all running. And that’s not including the pumps and sub-systems that were run by electric motors. Steam turbines ARE NOT quiet! And propeller shafts spinning 18’ props at 220 rpm aren’t quiet either. I’ve read that the MRG makes all kinds of noises too, even when in perfect running order.

I also found that the foundation holding up the massive HP Turbine is a rectagular heavy I-Beamed weldment that is supported on end by additional triangular braces on the forward end of the main reduction gear, and has its other end simply resting on a shelf-like bracket on the boiler-engineer room bulkhead. There are no separate foundation legs or supports holding up the hp turbine. Ryan was surprised to see this since he didn’t think the bulkhead thickness had the helf to support a 30,000 pound, vibrating machine.

I took 80 pictures and one 3D scan of the curved inlet end of one of the two auxiliary steam turbine electric generators. I also just discovered that my Scaniverse APP on my iPhone 12 Pro is much more versatile that I knew and that I using the wrong file type to import the processed images into SketchUp.

I have to decipher the images I took. Many are like the analogy of the blind men trying to describe an elephant when each is touching a different part. For example: the main steam pipe runs out of the boiler room bulkhead and the follows a ridiculously long path before reaching the HP turbine. At one point it makes a 180º turn back on itself. We assumed this is all to manage expanision issues since the steam in that pipe is over 800ºF.

I was in areas that most people will never go. Access around the HP turbine, in general, is very tight and visitors would not be allowed there, if (and it’s a big if) this room was to be re-conditioned and opened to the public. Making matters worse was most was completely unlit and I had a 1,000 lumen flashlight that I used for most of the images.

Here’s a confusing taste of what I saw:

Astern Steam Lines: These lines snake back and forth providing 800# steam to the two astern turbines on each end of the low pressure turbine spool.

The air ejector unit is a rather small and ridiculously complicated maze of piping and valves. It’s purpose is to remove entrained oxygen from the feedwater condensate coming out of the condenser before sending it to the boiler room. While I think I can model and print it, I’m not sure why.

There are seven of these cam operated, spring-loaded throttle valves perched on a manifold atop the HP turbine. They are manually operated in sequence by a large hand wheel on the main control board. as the wheel is turned, the cam is moved via a gear box which opens each valve in order to increase or decrease steam inlet. I will be modeling these!

These are water collection points under the HP turbine. Just how much of this I can/will model is anyone’s guess at this time. You won’t see much of it. I don’t yet know where this water ends up. It’s hot, as noted by the insulation wrapping, and it’s basically distillate and is relatively pure with probably traces of the lubricant and it wouldn’t be wasted. I will find out.

Looking up under the HP turbine you can see part of the weldment that holds it up. The large flange on the right side is on of the center joints of the main condenser. The HP turbine nestles up against it.

The other end of the frame rests on this support welded to the boiler room bulkhead. This is a two-image composite.

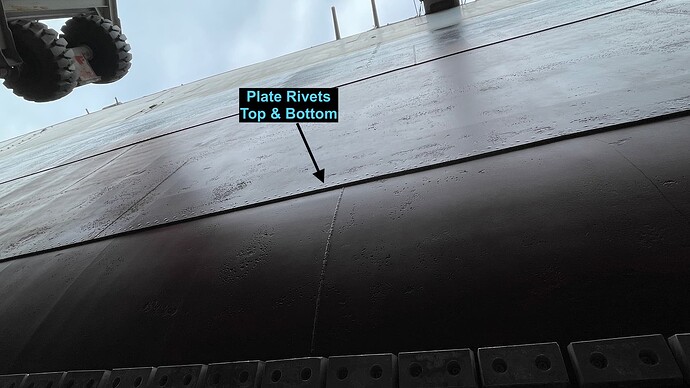

As you can discern, it’s not overly complicated. it will require that some portion of that bulkhead to be included the model. The other suggestion that my older grandson made was to detail the far wall to show the ship’s framing and the armor plate installation. Ryan thought that would be a good idea. These is actually very little equipment of interest on the port side of the engine room with the upper deck having electrical switchgear cabinetry and the lower deck being completely bare.

This is the kind of stuff that makes this model both enjoyable and a bit scary. Working with no net!