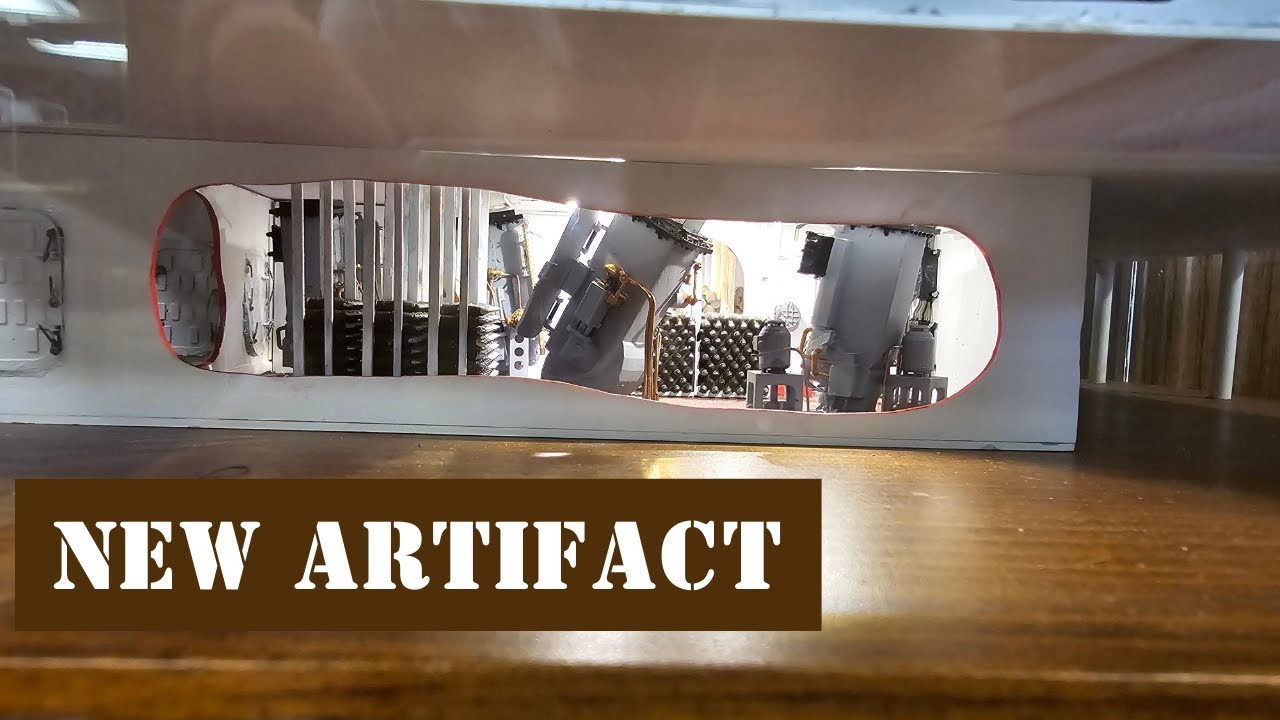

For all of those followers that had the patience to spend almost a year each for the two models that I created for the Battleship New Jersey Museum & Memorial (16" and 5" gun systems), my next (and final) major project for the ship has now begun. Here’s Ryan Syzmanski talking about those models.

I noted in my last posts on the 5" project, that the engine room was on the docket, but it needed dimensioned engineering drawings to proceed. I spend several hours in the engine rooms taking lots of pictures, but without the dimensioned drawings, I would be shooting in the dark. Due to the complexity of the space, dead reckoning like I was able to pull off on the other two wouldn’t work on this one.

My search of the National Archives produced a very promising set of original drawings for all the New Jersey’s engineering, and I had even planned a trip to College Park, MD to view them. That was until I realized that I was looking at the drawing index of the Battleship New Jersey BB16, built in 1905, not BB62 built in 1943. Who knew there were two of them?

They did find microfiche drawings, but their computer system wasn’t working correctly and I couldn’t get details on what drawings were in the set. Then John Miano came through.

John wrote a terrifc photo study touring the Big J with terrific pictures of the engineering spaces.

“A Visual Tour of the Battleship USS New Jersey” Copyright 2021 John Miano, Collesseum Builders, Inc. ISBN 978-0-9099804-3-2

I wrote to him asking if he could assist in the project. Ryan Syzmanski, the Big J Museum curator introduced him to me. John did have some drawings that will work, but the were large files. I finally realized that my DropBox installation could be used to capture John’s files even if he didn’t have the app on his system.

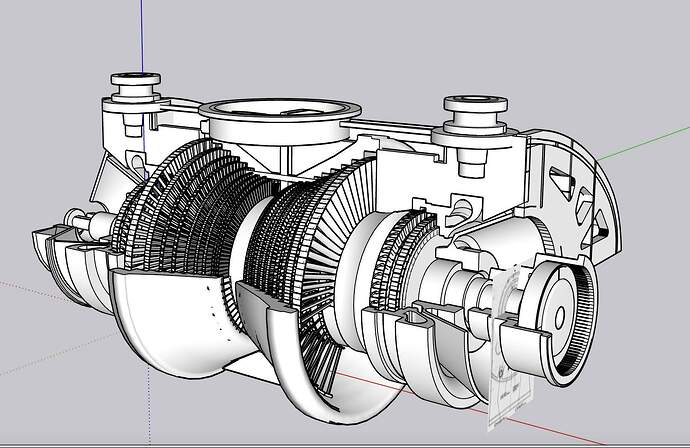

The files arrived yesterday and this morning. They are terrific! I still need more specific drawings of critical machinery mainly the HP and LP turbines and the Main Reduction Gear, but their outlines plus pictures may be enough to do something. I also have specific details about every latdder and grate in the entire space, down to the specific bolting details of how they’re fastened to the structure.

I need more info on the structural girders, but I can probably ferret that out. I finally have imagery of the massive foundation steel that supports the equipment. You can’t see that on a visit unless you want to crawl around in the bilge and that ain’t gonna happen.

This project is more complex that the previous two… I know, I know, that’s hard to believe, but believe me. I’m planning on doing milld cutaways of main propulsion plants and the reduction gear. There are over a dozen different sized ladders that need to be produced. I’m planning on 3D printing the floor grating so it will look pretty good especially with lighting showing through it. The #2 deck above will not be there so the main equipment floor will be fully visible. The model won’t be overly large at 1:48, but it will be complex and interesting. It may also get an AV program to highlight aspects that won’t be evident once it’s all put together. This is the same approach taken with the 5". Ryan’s communication person is helping to produce that for me to put up on the Internet.

Here’s a taste of one of the drawings.

So… fasten your seatbelts. If this is anything like the previous two, there will plenty of successes, near misses and out-and-out castrophes to deal with. Only the strong of heart should proceed. I will start drawing as soon as I finish editing my book on 21st Century Model Making. Stay tuned to this space.