Well guys, as part of the Convoy Campaign, I’m building a modern truck or two, including the JLTV - UTL, which is basically a pickup truck version of the M1278. A few weeks ago I purchased one of these kits from Sabre Models, so it will serve as the basis for this project. I don’t want to clog up the Campaign thread with too much of the construction so here we are.

If you’re not familiar with the JLTV, it’s broadly defined as the HMMWV replacement vehicle. The UTL version looks like, and is described as:

Being a truck enthusiast, this caught my eye as a fun project.

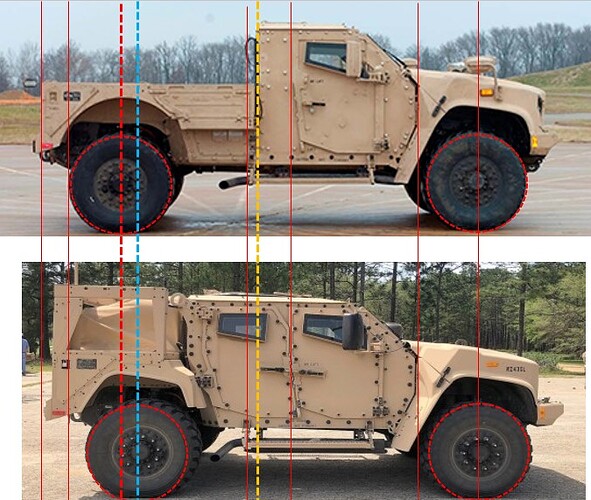

Before jumping right into this, I prepared this visual study:

While admittedly low tech, this illustrates a few key points for this conversion. First, refer to the dashed red, and blue lines - the UTL version certainly appears to be a bit longer than the standard version. Unhappily, I can’t confirm that this is the case or not - is it just an optical illusion? well, I don’t know, but am living with the conclusion that the UTL is a bit longer.

Next, for general orientation the dashed yellow line represents the rear of the UTL cab, and you can see where it hits, about halfway through the standard model’s rear door. To the left, you can see a thin red line - it turns out that the running board length of the two trucks is the same, which is very helpful, as the kit includes some well defined mounting points in this location.

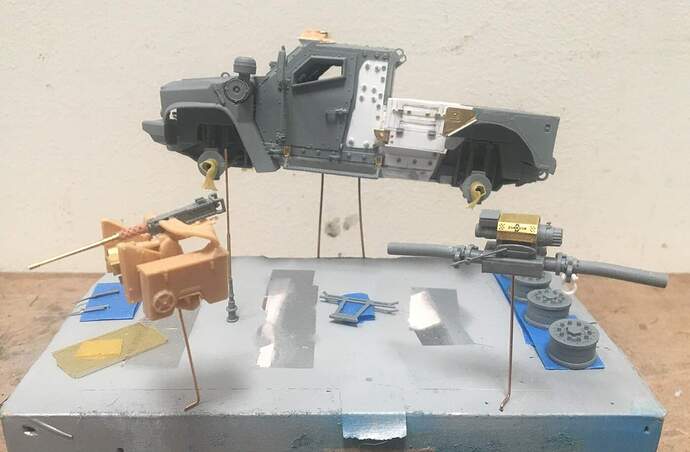

So, with this suspect information in hand, I went about cutting:

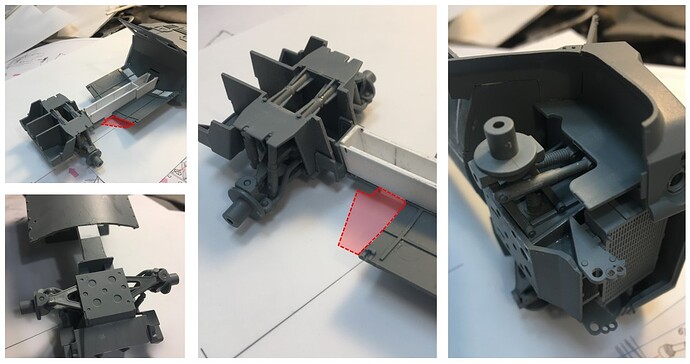

I realized I didn’t include a before picture - perfect! So, the chassis on this model is actually the hull of the truck, which is characteristically similar to what you see under an MATV, rather than a typical two rail, or unibody chassis.

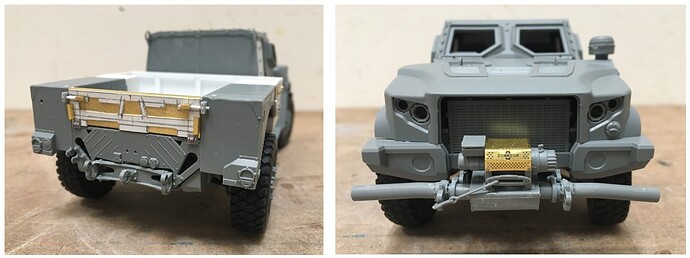

For the build, the hull was cut right next to the running board mounts - you can see in the red shaded area where the hull was. I did not cut this straight across, and instead kept a short segment of the rear of the hull in place, as you can see in the lower left picture.

Then, measured the approximate distance I needed to add to get closer to the right vehicle length, and added a longer sheet of styrene to the short segment to the rest of the hull, adding a small filler piece (the short sheet of evergreen in the pic) to get the chassis to the desired length - whoa - sorry about that rambling description!! bottom line, the hull is longer now ![]() and, as hoped, is rigid!

and, as hoped, is rigid! ![]()

Next, added what looks like a trans tunnel - but it’s not - because I cut the back off, there was no longer a way to support the floor of the crew cabin, so the tunnel is a base for the floor to rest on, and adds more stability to the whole thing.

This process went relatively smoothly - I made some measuring mistakes, but was able to get things where I want them to be ![]()

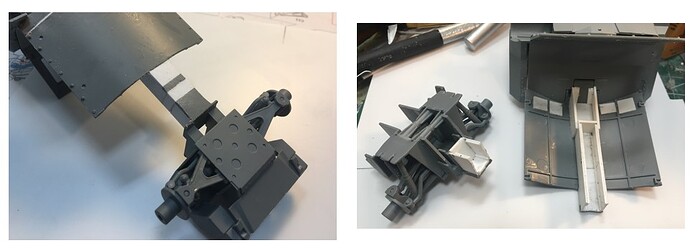

The Sabre kit is pretty nice, it goes together pretty well. For those of you familiar with building MATVs or other vehicles with the TAK4 suspension, you are familiar with some of the challenges - a third hand would be useful! All of the parts work as they’re supposed to, but assembly requires some patience.

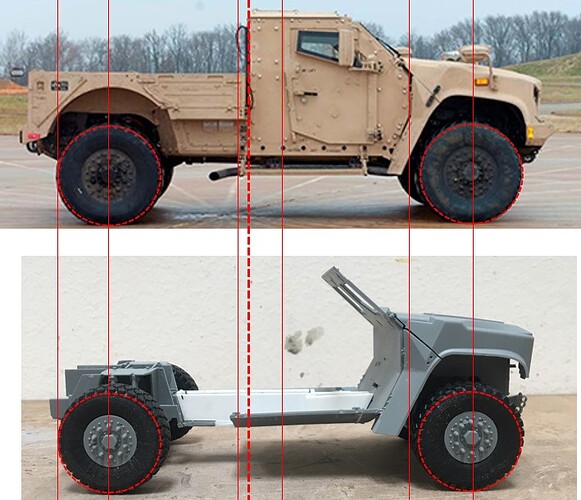

And this is how it worked out:

Again - an optical illusion? I really don’t know, but I’m sticking with it! The kit includes posable steering which is really pretty easy to build - much easier than converting a kit not intended to steer!

As a scale reference, I compared an HMMWV, this, and an MATV:

I think it looks pretty cool. I’m also an off road racing and driving enthusiast - I like the styling, and that the rig includes dual front and rear shocks, what appears to be a fair amount of suspension travel, and good chassis clearance.

OK, on we go, thanks for having a look,

Cheers

Nick