Hello gents,

I’m starting a new project, which I’m really looking forward to:

What a beauty!

The KW 963 S, is a large, 6x6 used for oil field work - it is a beast! The engine is a Cummins ISX, which turns out about 3,600 HP at 2000 RPMs, and is capable of carrying 100,000 lbs - so, a big truck.

A long time ago, I built on using a resin kit and some scratch work, but in 1/87 scale:

While pretty cool and with nice detail, it’s pretty small - and the tires are not tall enough.

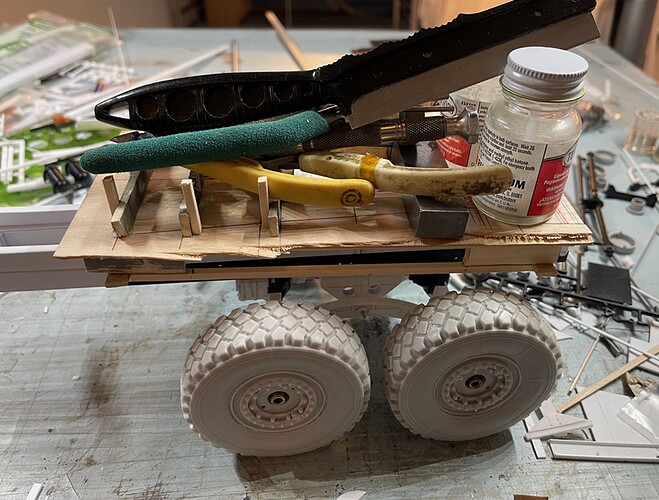

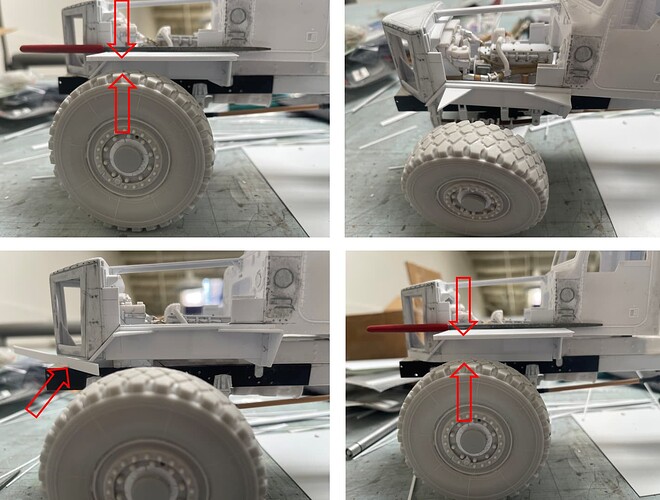

I’ve pondered making one of these for a while, and have not done so because of those tires - they are huge! 73" in diameter. While talking with another model builder about this, I thought to look at the 1/16 scale MATV kit I’ve had sitting for a few years - the tires are an almost exact match:

At 1/24 scale, the tires, at 3" in diameter are an almost perfect match, and the width is correct. The wheel size is a bit large in diameter, but I can live with that. I looked on ebay etc for for a few more of the tires, as this is a 6x6 with no luck, so, I opened the wallet and ordered a resin set from Blast Models…all I’ll say is they are not cheap, and on their way to me. Oh, and while the pics of the real truck show a different tread pattern, I happily have other photos that show a similar tread!

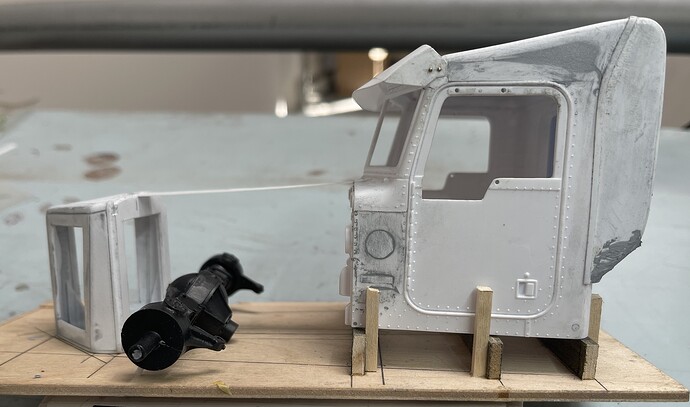

While waiting for the tires, I started work on the cab. This is a bit tricky. Most KW models are in 1/25, and reflect an older style cab. I want something closer to the newer version, specifically the 963, not the 953.

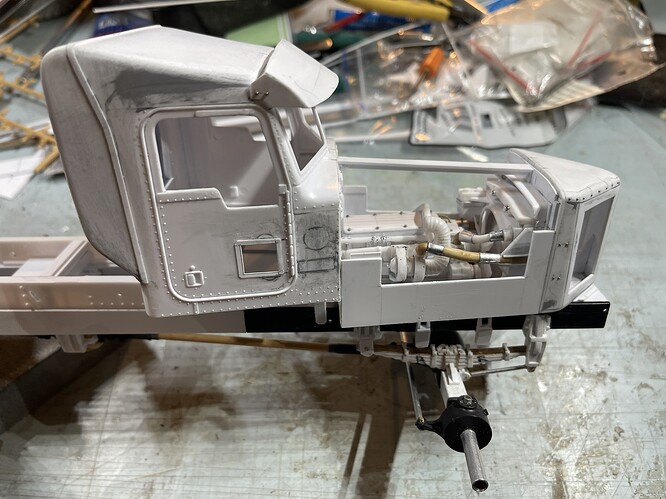

So, I decided to start with, and here, I encourage some of you to take a deep breath, a 1/24 scale…Peterbilt cab - - I know, just try and shake it off. I did this because while some of the the basic geometry is off (the KW has a flatter wind shield), the overall structure serves as a better foundation for change, than the 1/25 KW (which surprisingly, does not have the flatter windshield?)

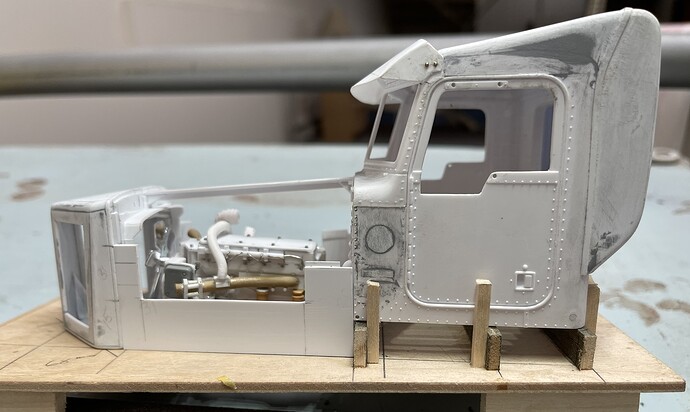

So, here we go:

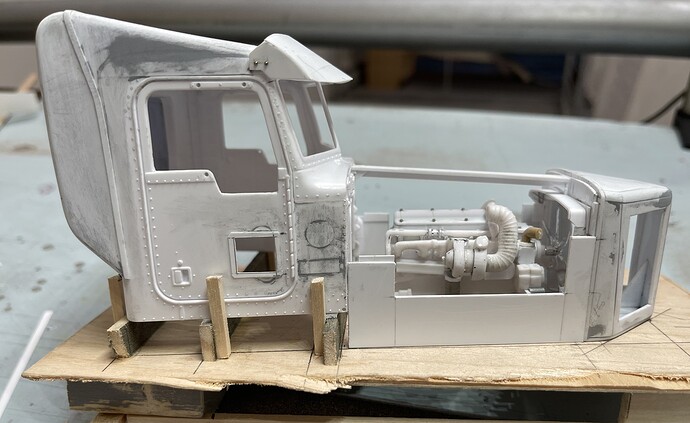

There is plenty going on here - the doors were cut to look like a modern KW, the lower window on the passenger side re-cut to look like the KW version, and the rear and top of the cab reshaped to match the KW.

The visor was a PITA and too a lot of thought and time to resolve. The Peterbilt base cab has a “V” shaped window, and while not completely flat, the KW does not look like a “V”. So, in order to create the illusion of a flatter window, the visor has a long flat curve on the lower edge which when viewed downplays the “V” shape, while retaining the basic look of the actual part.

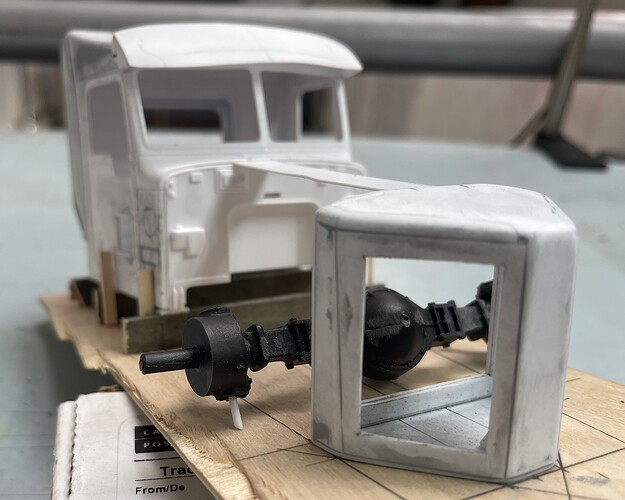

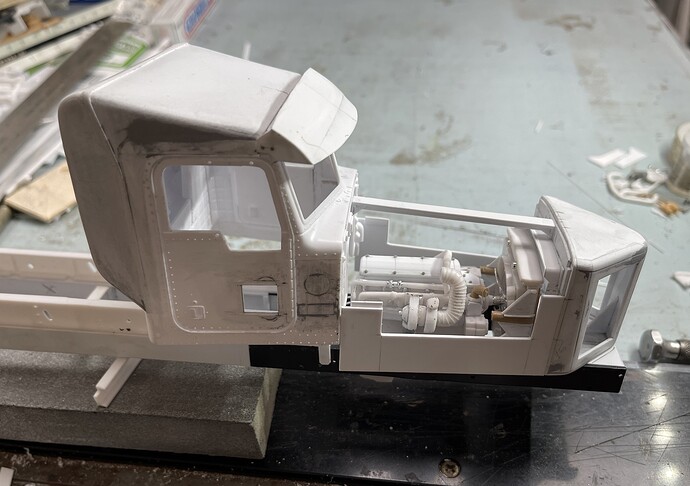

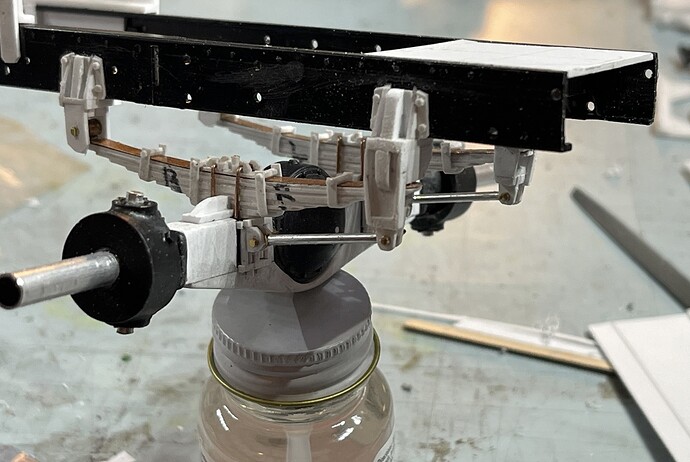

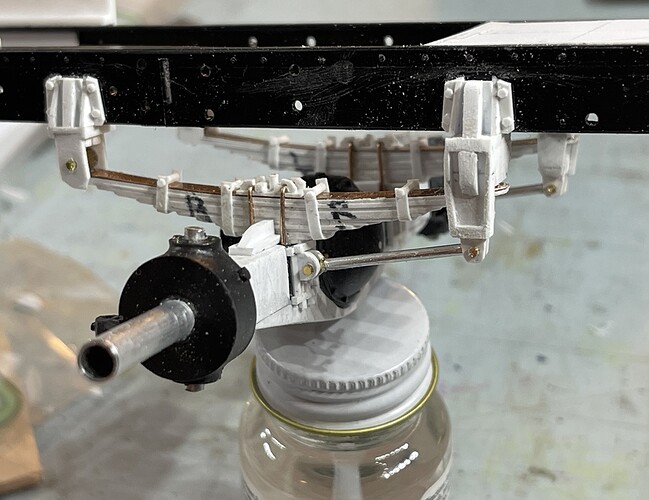

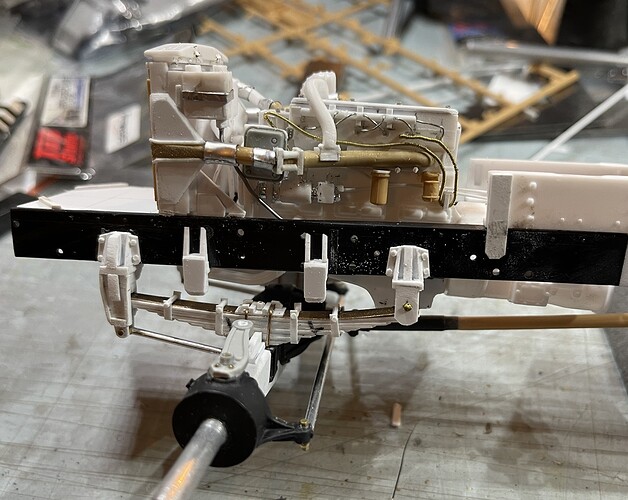

Another challenge is that this is big, and the hood nothing like a normal truck. To address this I made up a jig with the overall shape drawn onto it. As this truck uses a partial twin rail chassis, the cab sits higher than where the hood rests, so it’s elevated.

Ok, a guy could go on and on - but won’t. Following the cab, I made the basic nose - which is almost exactly 1/4" lower than the sil that the hood rest on below the windshield - oh - again sorry!! too many words! ![]()

Another real challenge to make! that nose!!! ![]()

![]()

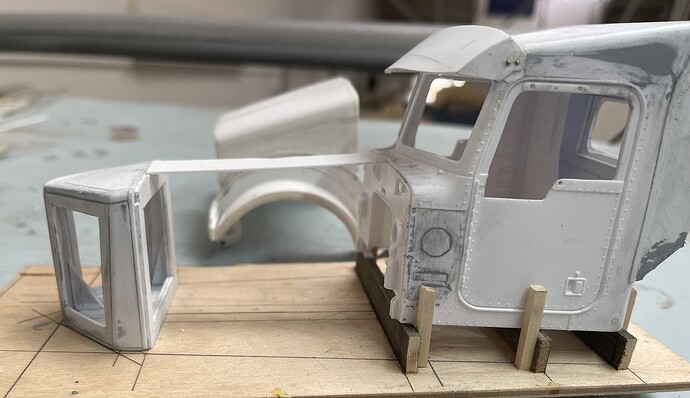

![]() (oh, and the visor does not look this wonky - an optical illusion)

(oh, and the visor does not look this wonky - an optical illusion)

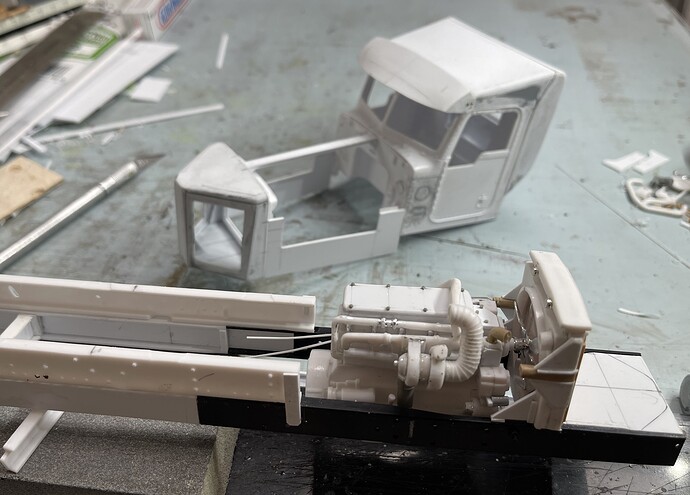

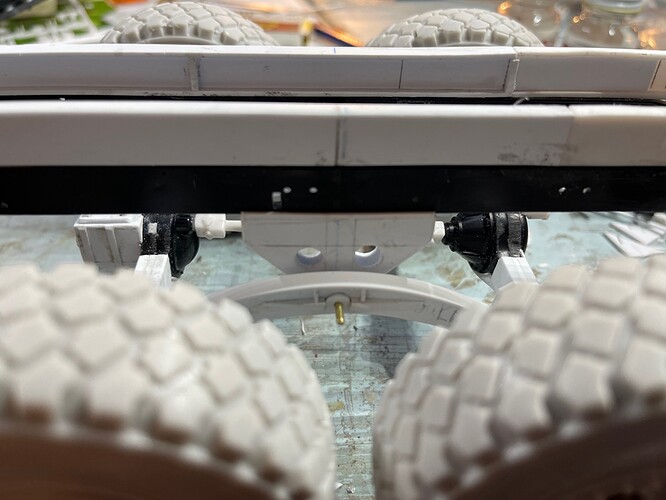

And for a basic comparison:

In the background is a hood I made and didn’t use for a Peterbilt 348 - and you can see it’s steep slope and comparatively short length. The 963 hood does not tilt and is instead hinged in the middle.

So, on we go - thanks for having a look -

Cheers, Merry Christmas, and happy model building!

Nick