Hello model builders,

I’ve read several posts here regarding civilian reuse of the M1070. So far, I have been left to wonder about these conversions.

The dump or water truck, seem like overkill, and not the best use of such a versatile truck. I have seen a few applications where the truck is used as a prime mover for heavy haul projects - houses, big materials, and so on. I saw one that was converted to a camper - and others converted to wreckers. Of these choices, the wrecker seems most reasonable, but that’s not what I want to build.

Instead, I got to thinking about an oilfield winch or bed truck:

As you can see above, the oilfield truck and its variants. There seem to be three obvious choices - cab with a 5th wheel, like the lower right, a 6x6 or 8x8 bed truck like the upper right, or, an 8x8 tandem/twin steer. Guess which won? The 5th wheel seems a bit easy, and I recently built a Peterbilt 6x6 gin pole truck in 1/24, so, the tandem it is!

I realize this is totally impractical ![]() But, it will be a lot more fun to build than the other options!

But, it will be a lot more fun to build than the other options!

These trucks (tandems) are available in several drive axle variants - 8x4, 8x6, and 8x8. While these pics are Kenworth trucks, others manufacturers make them too - I found lots of photos of a Western Star 8x8.

So, this is what I’m up to, converting an M1070 to a tandem oilfield bedtruck. I’m posting this in Armor and not Autos (ie civilian) because the subject pops up enough that people seem to be interested.

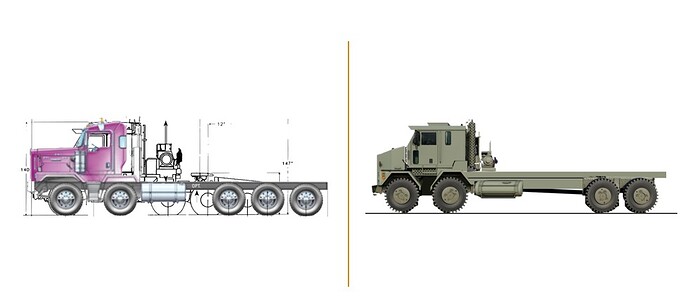

First task, some graphic studies:

The image on the left is an overlay of a KW on a line drawing of the M1070. The KW image comes from their Body Builders Manual. You can barely see on this small image how the basic geometry might work. On the right, some cut and paste illustrating the intent.

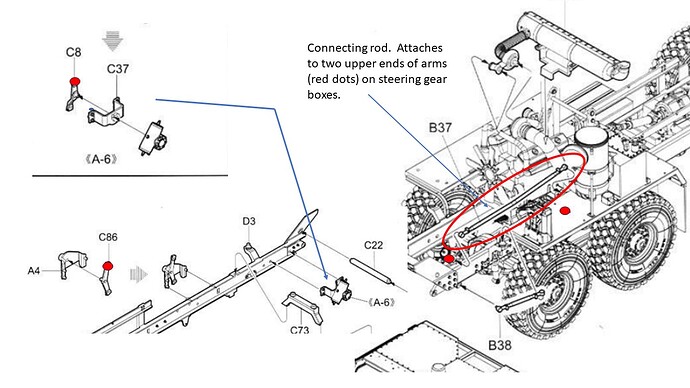

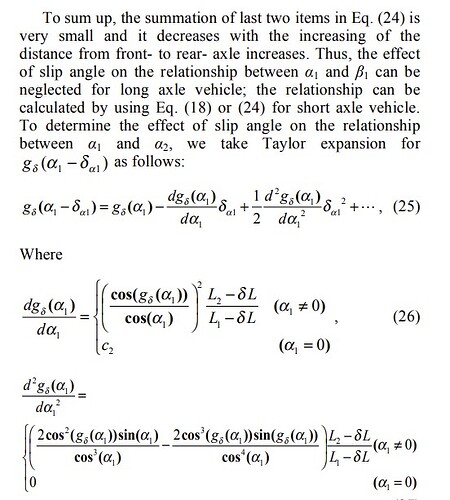

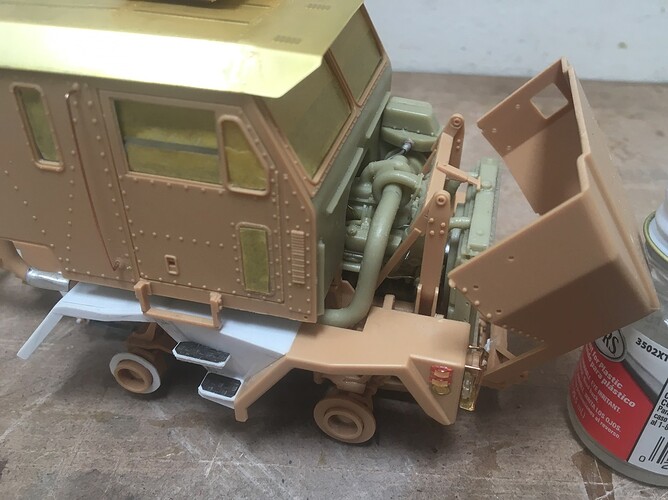

It turns out the M1070 has two steering axles, one in the front and one in the back. So the idea is to move the rear steer axle forward, and mount it on leaf springs. Then build the remaining two air-ride axles to the back, basically as intended. Then, cut and lengthen the chassis.

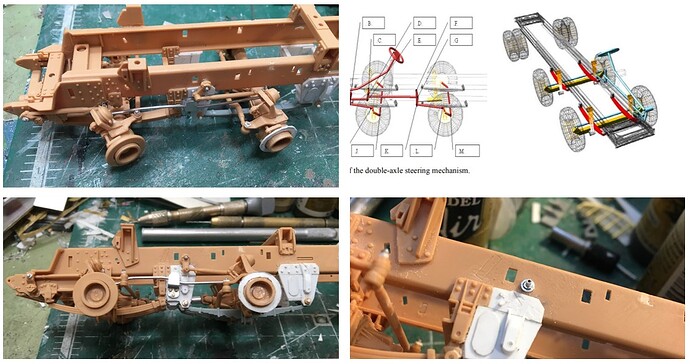

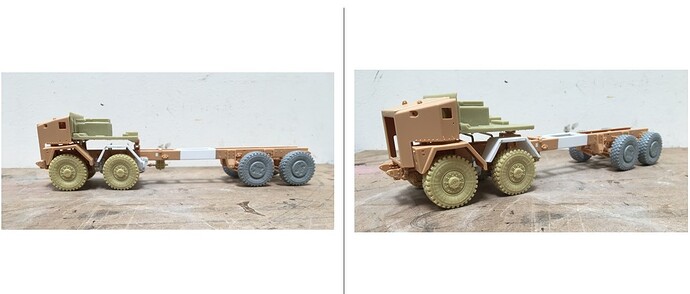

And where we are now:

I’ve had the Hobby Boss M1070 kit sitting in the stash for a long time and decided now was the time to get after it. I’ve also got a Real Models engine and transfer case, and don’t remember who made the tires/wheels.

A brief editorial on the HB kit - while it goes together reasonably well, the parts are not grouped in the sprues - that is you’ll use parts from sprues A, E, J and H on one assembly…perfect. As there are a lot of parts being used, this gets tedious. The instructions are fairly clear, but this might not be an ideal kit if you’re newish to model building.

I decided to build the basic layout on the short chassis in order to get it sitting level before it gets hard to handle. So far basically so good. For the front, I added some remnant leaf springs and am building brackets - not sure yet how I’ll get the steering to work out, as this has two steering gears, and steering movement is coordinated…hmm how to address that? ![]()

My “simple” approach to the rear end has not been that simple - as a few parts went to the front and a few stayed in the back - meaning driveshafts, torque rods, and on an on, almost but don’t quite fit, so more cutting and pasting in plastic! ![]()

The basic victory so far is that it almost sits flat - I’ll keep working on the ride height. And, again, the rear end…almost but not quite there.

Thanks for having a look,

Cheers,

Nick