A bad thing happened to me at the start of August. I was at a show and was tempted into an impulse buy. I came home with the AHHQ/Takon M113A1 kit…

Those of you with a (very) long memory may recall I used to run a website dedicated to the M113 back in the late 1990s, so the vehicle itself holds no fear for me and I must have built upwards of 30 1/35 examples over the years. But 1/16 scale? That’s way outside my comfort zone!

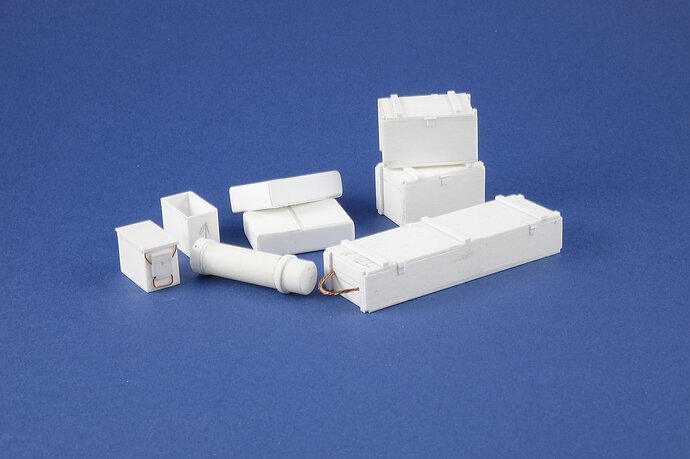

I’m going to try and record my progress on a semi-regular basis but this may be a long project so please don’t expect weekly updates. I’ll post when I have something worth posting. My plan is to do as much of the work as I can without recourse to aftermarket items. That includes most of the stowage, but we’ll come to that in good time.

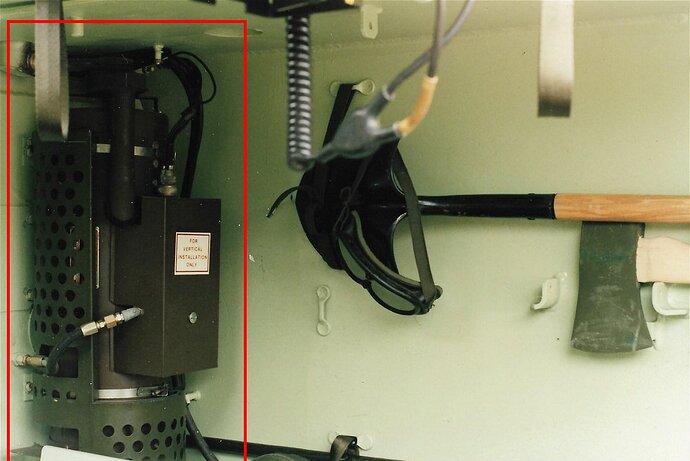

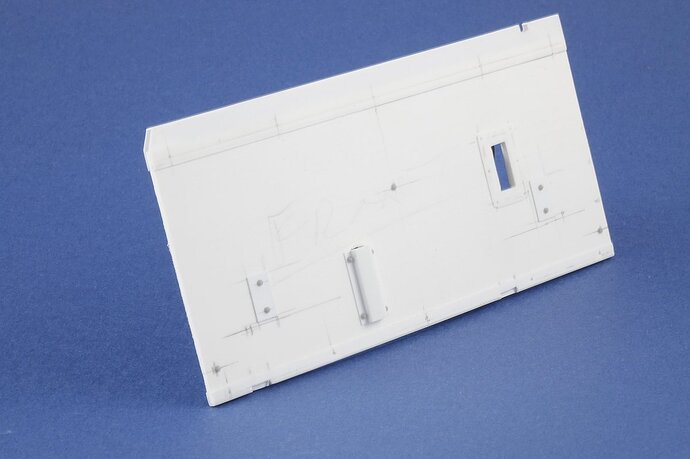

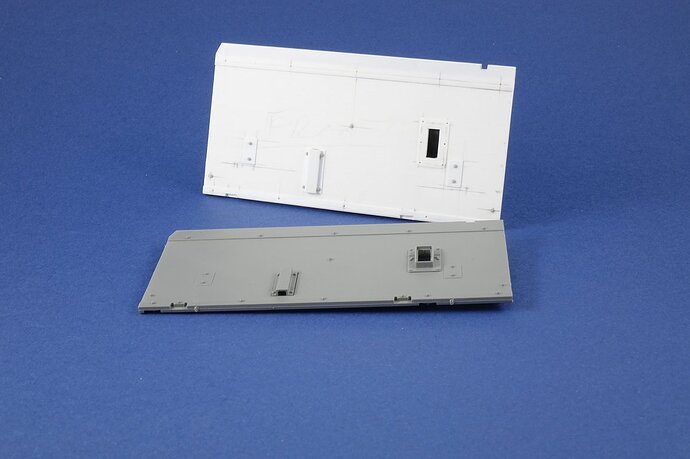

The kit has been reviewed elsewhere and it’s a great kit with plenty of detail. The problem is that in this scale, it has nowhere near enough detail for an obsessive like me. Immediate red flags from my perspective are that the fuel tank is not plumbed in; there is a lot of cabling and ducting missing inside the vehicle and the moulded-on cabling has just got to go, not to mention the kit’s splashboard being a compromise I can’t live with. Then there’s the fact it’s an A1 and I want to build an A2.

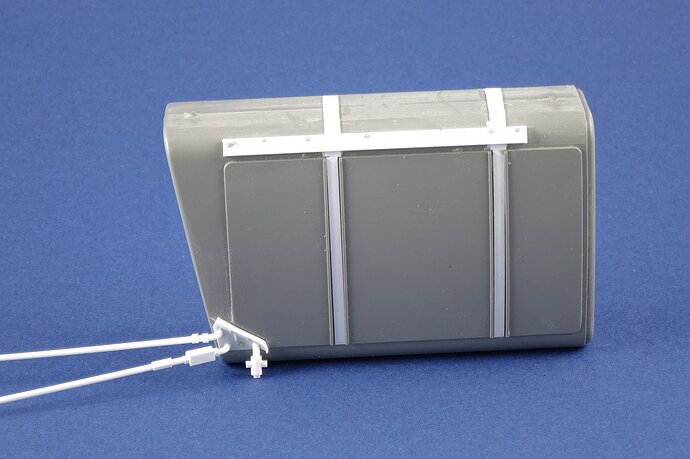

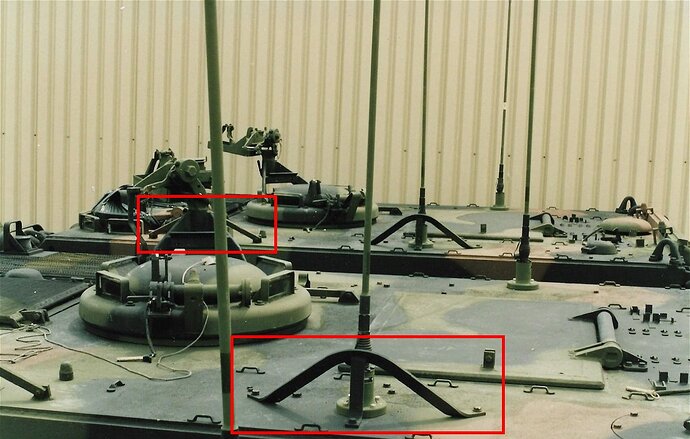

So where to start? Research, lots of research. I spent some time digging out all my books that cover the M113 and refreshing my memory. I also rediscovered a couple of walkrounds I’d done in the 1990s so I’m going to start by introducing to my friends Huey and Dewey, and their pal Red Nose (British modellers will recognise the visual reference). I’ve also started work on the fuel tank. The pipes are loose at present because when I fit the tank I will want to guide them down and along the floor edge.