Yes the one over the rear turret ventilator.

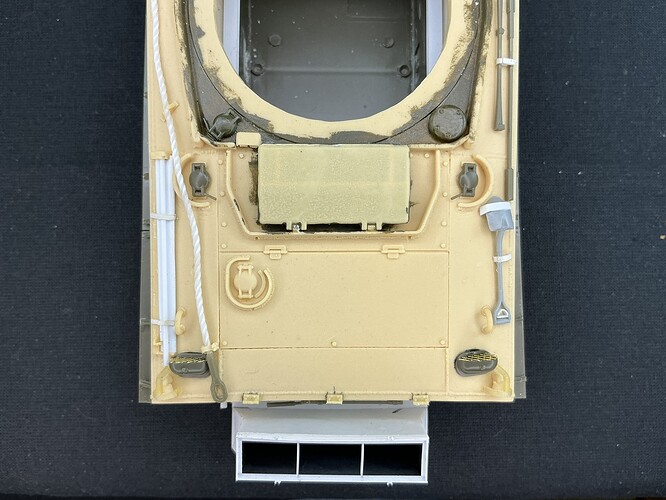

The tools etc. are now also on:

The white plastic on the left are the gun-cleaning rods for the gun, with under it a bag with the red-and-white aiming stakes that are used for indirect fire. I think the tow cable (thread from another kit) is too thick, so chances are I’ll replace it by something thinner.

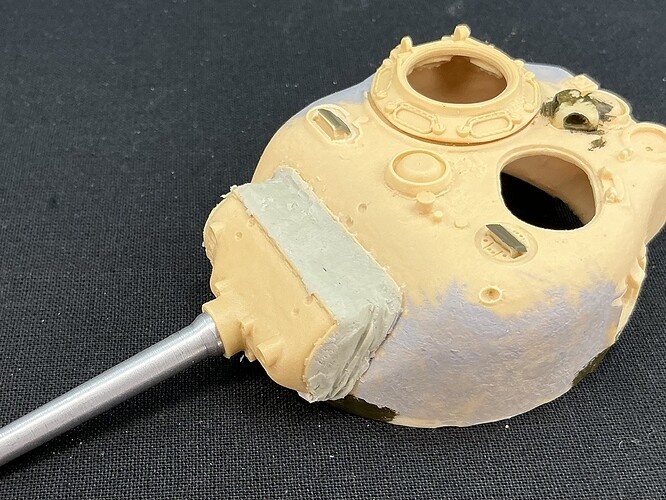

The front of the turret actually represents a fairly late version:

You can tell by the little blocks around the strip to which the canvas cover for the gun mantlet attaches, so those had to go:

There was also a hood over the gunner’s periscope, but I already sawed that off earlier because it’s also a feature of the later 105 mm Shermans.

With Magic Sculp, I made the canvas cover for the gun shield:

Earlier, I had scrounged up a crew, and because I had the Magic Sculp mixed up and left anyway, I also made a few small changes to them:

From left to right first the assistant driver, an Asuka figure whose pistol belt I cut away and whose coveralls I modified into a jacket and trousers. Then the commander, which is an upper body from MiniArt with a helmet from the spares box, and a little bit of lower body made from the remains of the Magic Sculp because when he’s in the hatch it was just a little too noticeable that his body ended at his waist. The driver is from Tamiya with Asuka goggles, and the loader is another MiniArt figure with lengthened trouser legs so his uniform can pass for 1945 Pacific style, so without leggings — it doesn’t need to be any better than this because his legs will be dangling in the loader’s hatch. His flesh has a base coat of paint from a previous employment opportunity that did not come to pass.

Very nice progress on your M4 Jakko. I like the figure modifications as well.

Here’s an overall shot of what I have now:

I did remove the tow cable and replaced it by a thinner one, for which I also had to use different eyes:

Because the old cable was threaded through the front and rear clamps and was partly glued to them, I had to cut those off the model. Fortunately, I have a bunch of those from Tiger Models in grey resin, so that was not a big deal.

And now the canvas cover is done, I could continue adding details to the turret:

The lifting eyes, periscope covers and folded-down support for the machine gun barrel are from Asuka, the periscope brush guard dfrom RFM (I think), and the covered machine gun (which is not glued on yet) on the back is also by Tiger Models. To make sure it won’t break off, I drilled out the support for it, inserted a bit of 1 mm brass rod, and glued that into a corresponding hole I drilled into the back of the turret. To the loader’s hatch, I added a grab handle (not visible), and I need to add some more details to the turret before it’s done.

After more peering at the available photos, I replaced the .50 calibre on the back of the turret by a better one:

A very old, already painted one from Italeri ![]() Partly because it’s impossible to put the Tiger Models gun in the transport clamp (which isn’t on my model yet), but also because that Tiger Models gun is in a special cover with zip etc. while on the well-known photos from Okinawa, there appears to be a simple tarp over the weapon, with that transport clamp over the tarp. (This gun is still loose too, by the way. It’s “better” because it will get covered up completely, and for that I prefer to use a part that’s as poorly detailed as possible yet still of the right shape and size.)

Partly because it’s impossible to put the Tiger Models gun in the transport clamp (which isn’t on my model yet), but also because that Tiger Models gun is in a special cover with zip etc. while on the well-known photos from Okinawa, there appears to be a simple tarp over the weapon, with that transport clamp over the tarp. (This gun is still loose too, by the way. It’s “better” because it will get covered up completely, and for that I prefer to use a part that’s as poorly detailed as possible yet still of the right shape and size.)

Making the brush guard over the gunner’s periscope was a “fun” job. It’s about the same size as the others, but the legs are completely different. For strength, I first drilled holes and glued overlong pieces of brass rod in them:

Next to the turret is the rectangular part that will go horizontally between those legs. After the glue on them had dried, I bent the legs inward and glued the rectangle between them:

Though that sounds far easier than it actually was … If I had better soldering skills, I think I would have done well to solder the legs to the rectangle and then bend them to fit the holes I drilled in the turret. But I can’t solder all that well, so I had to use superglue instead. Once that has thoroughly dried tomorrow, I’ll cut the legs down to the level of the rectangle.

It may appear like the rectangle is leaning backward, but that’s an optical illusion in the photograph. It is actually horizontal relative to the turret roof.

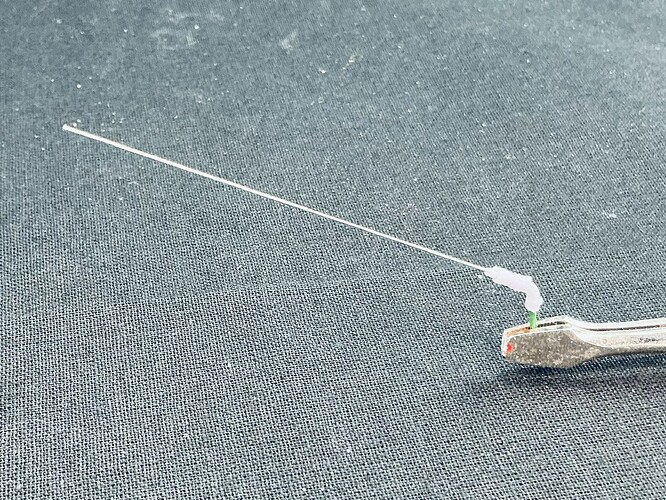

I’ve also made an antenna:

The base is by MIG, 3D-printed. I drilled a hole into it at both ends: in the top for 0.3 mm spring steel, 52 mm long to represent two antenna sections, and in the bottom for 0.8 mm florist’s wire which will go into a corresponding hole in the turret roof. That 3D-printed resin is not a nice material to drill with a bit as small as for the antenna, it’s pretty hard and you can only go very slowly.

Trimmed to size with my cheap cutters* that are specially designed for thin copper wire:

The commander’s hatch is also done, so I glued that in place too.

* A few years ago, in a store selling second-hand tools I came across some cutters costing €20 — a lot of money compared to the other cutters there. They seemed like good quality, though, so after some consideration I decided to purchase them. I got a bit of a start when I looked them up online.

Ah!

Lindström cutters, made in Sweden ![]()

I hear they are so expensive because there is metal from a Viking axe in each pair!

Damon.

I must say I’m happy I bought them, though — they cut one end of the wire pretty much square, which makes them very useful for this kind of model work because it means I don’t need to file the ends of the wire. I’m very careful with them, though — I don’t want to damage them and have to pay full price to replace them ![]()

The real tanks had sandbags covering the engine deck, so mine now has too:

These were made from Sylmasta A+B putty, and for the first time in my life I had mixed up exactly enough ![]()

I also made holes in the back and front of the exhaust duct (though slightly larger than I intended to) because today I noticed it on a photo of the real tanks. It answers the question of, “How did they start the tanks when they had that thing attached?” (Because the radial engine in the M4 and M4A1 needed to be hand-cranked for four revolutions before starting, using a crank stuck through a hole at the top of the upper rear hull plate.)

Excellent job Jakko. I need to get some bent antenna bases myself.

Did those holes have flaps to waterproof them? The hole in the rear hull wall also needed a plug…

I looked at a higher-resolution version of the photo, and have come to the conclusion that the holes are factory-installed, so they must have come with some kind of plug or cover. Which means that the ragged hole I made (based on the assumption that the crews themselves had made them) needs cleaning up/correcting, which will be fun to do in material this thin …

Taking an even better look at the photo, there’s actually a pipe running fore-and-aft through the holes. So I’ll need to add that now …

That would explain how it’s sealed when it’s in use. Clever.

The wading gear problem is now solved, too:

I sawed a length of 2.4 mm brass tube and opened up the inside a little with a round file, then glued it into the duct. I also removed the two bits of strip in the upper opening of the duct and replaced them by some rod a little lower down, because though the strips were there on the M4A3 duct, they were not correct for the M4/M4A1.

That looks better! Does the tube extend to/through the rear hull to form a watertight conduit?

Not on my model. I have no idea if it did IRL, as I haven’t been able to find photos that show this area.

By now I’ve cleaned up all of the track parts (two per link), and then put the spare links onto both hull sides:

Each of the six sprues has one link in a certain corner, which didn’t come out of the mould wuite right: the eye is torn on one side, the same on all six of these links. I therefore used these for the spares, with the retaining clips made from some plastic strip and a punched bolt head.

The track itself is easy enough to build: just put two outer parts together so that the pins on one fall in the groove on the other, then glue the inside on. Put a drop of glue where the yellow arrows point to:

… and then press the inner part on — taking care that it’s the right way round, because it can be put on in reverse. Also be careful not to use too much glue, because you don’t want it running to the pins.

By the time I had just about doubled the length of this section, I noticed that one link came loose. That proved to be because there were no pins on it, and on closer inspection, I noticed the things I circled in red … Each sprue turns out to have one spare link that already has the retention plates I made myself ![]() Luckily, the glue wasn’t dry yet so I could get it out and replace it with a normal link.

Luckily, the glue wasn’t dry yet so I could get it out and replace it with a normal link.

In the past, I’ve also built this type of track from Trumpeter, and found those easier to put together (links in one piece, with pins you push in from the sides) but these Asuka ones have a hollow guide tooth that Trumpeter’s lack (but which is hard to see). On the other hand, Trumpeter’s tracks don’t need any glue, so you can’t accidentally stick two links together. I don’t think I have a preference for either of the two for a future model.

For the back of the hull, I’ve also finished the blanket rack:

It’s resin, and judging by the paperwork I got with the pile of Sherman parts, it’s by Formations. However, it’s lacking the stowage for the gun-cleaning rods. That’s not wrong, because it was only present on later Shermans, including all 105 mm HVSS tanks, both M4 and M4A3 — though on those, it didn’t hold any cleaning rods, because those were carried to the left of the engine deck. Since the main reference picture I’m using of these tanks on Okinawa show the empty rack, I added it from some plastic strip.